A kind of vibrating dough kneading method and dough kneading equipment

A vibration type, equipment technology, applied in the direction of mixing/kneading with vertical installation tools, structural components of mixing/kneading machinery, etc. The equipment is simple in structure, easy to operate and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] A vibratory kneading method, comprising the following steps:

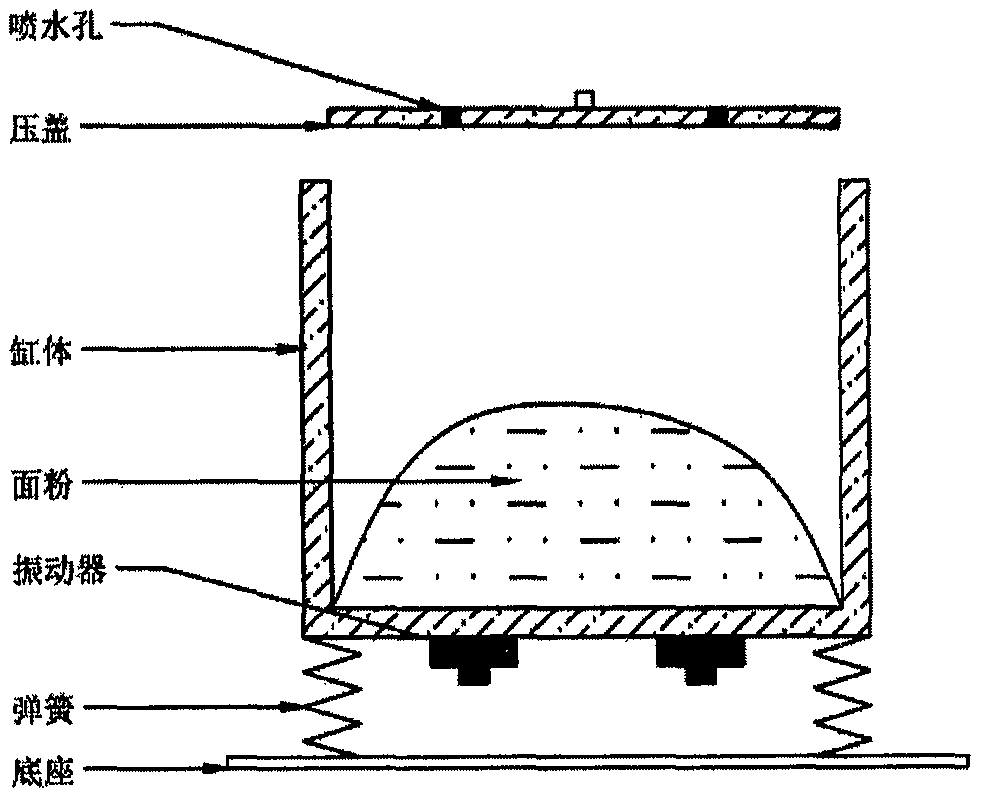

[0032] first step, such as figure 1 As shown, a certain amount of flour is poured into a cylinder with a vibrator installed at the bottom, and a gland with a water spray device is arranged on the cover, so that the flour is in a sealed cavity;

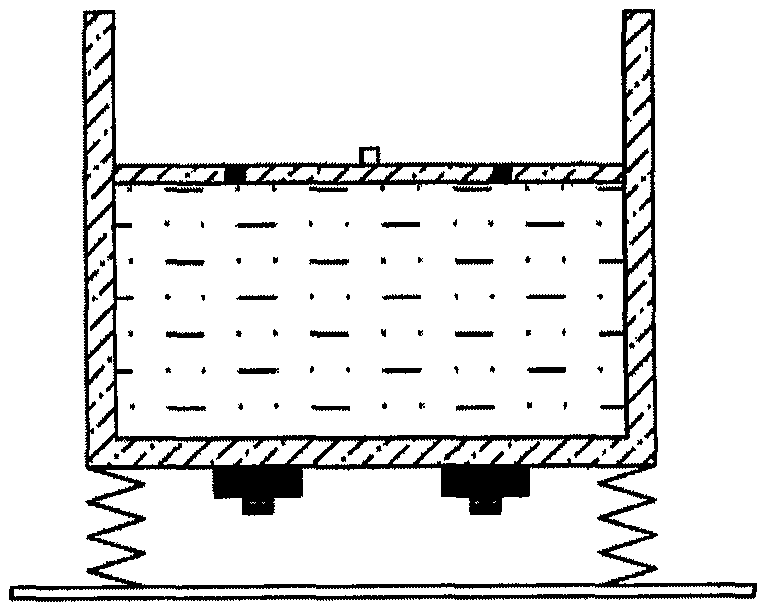

[0033] The second step, such as figure 2 As shown, open the vibrator to make the cylinder body vibrate up and down at low frequency, so that the flour in the cavity is raised, and the water spray device of the gland is opened to spray an appropriate amount of water to the raised flour in the cylinder body.

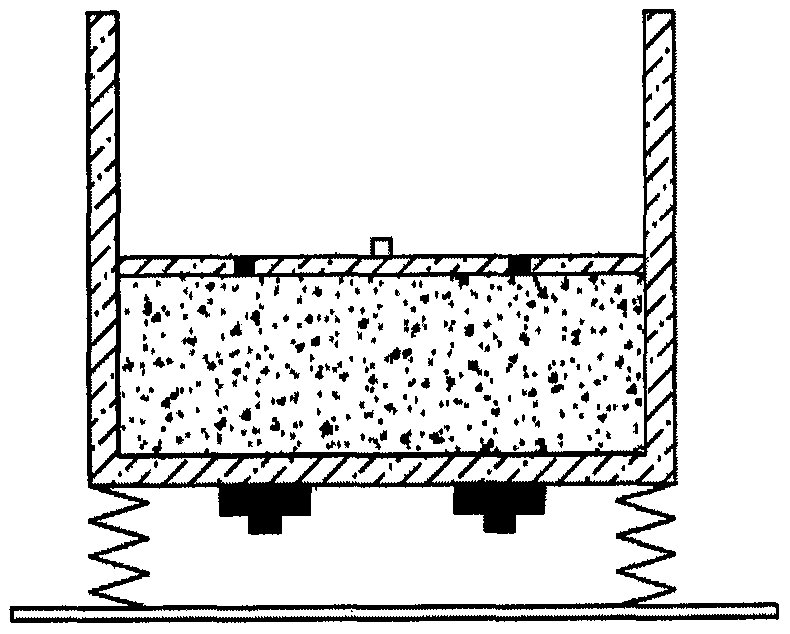

[0034] The third step, such as image 3 As shown, after spraying water, adjust the position of the gland so that the gland directly compacts the mixture of flour and water, and at this time adjust the vibrator from low frequency to high frequency. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com