Patents

Literature

58results about How to "Effective odor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano shell powder ecological functional flatly painted coating

The invention relates to environmental protection paint, in particular to nano shell powder ecological functional flatly painted coating. The coating is prepared from shell powder (calcined), ash-calcium, kaolin, heavy calcium carbonate, hydrated magnesium silicate, titanium dioxide, vinyl acetate, hydroxyethyl cellulose, polyving akohol, polydimethylsiloxane, a water reducer and a defoamer. The coating solves the problem that indoor ornament or decoration paint is not environment-friendly. The coating has the characteristics that the coating is antifungal, purifies the air, prevents mildew, adopts a spiral pore structure, is 3.0mm in press coating thickness and high in glossiness, does not has obvious color aberration, is resistant to shock, abrasion, water, high and low temperature weather and aging, and ensures that the service life of a product reaches more than 20 years.

Owner:通化市星赛尔生物科技有限公司

Diatom mud

The invention relates to diatom mud which is prepared from fine diatomite, methyl cellulose, bamboo charcoal and shell powder according to a certain weight ratio. With the diatom mud provided by the invention, indoor air can be effectively purified, wall surface reflected lights are natural and gentle; visual fatigue can be retarded, and fading is prevented. With the diatom mud, the wall surface can be kept new for a long time, such that wall surface service life is increased, wall surface decoration frequency is reduced, and household cost is reduced. The diatom mud is non-combustible, and causes no smog such as harmful gas. With the diatom mud, indoor air humidity can be automatically regulated, static electricity is prevented, and dust accumulation on the wall surface is prevented. The diatom mud is suitable to be popularized.

Owner:张维民

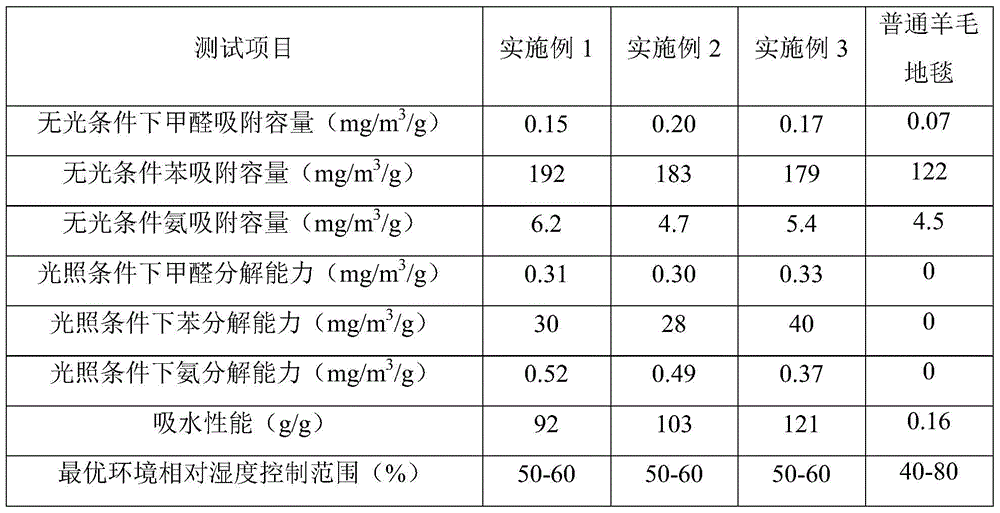

Method for preparing photocatalysis self-cleaning nanometer fiber felt

InactiveCN103966769AWith clean airEfficient decompositionFilament/thread formingNon-woven fabricsCompression moldingOrganic solvent

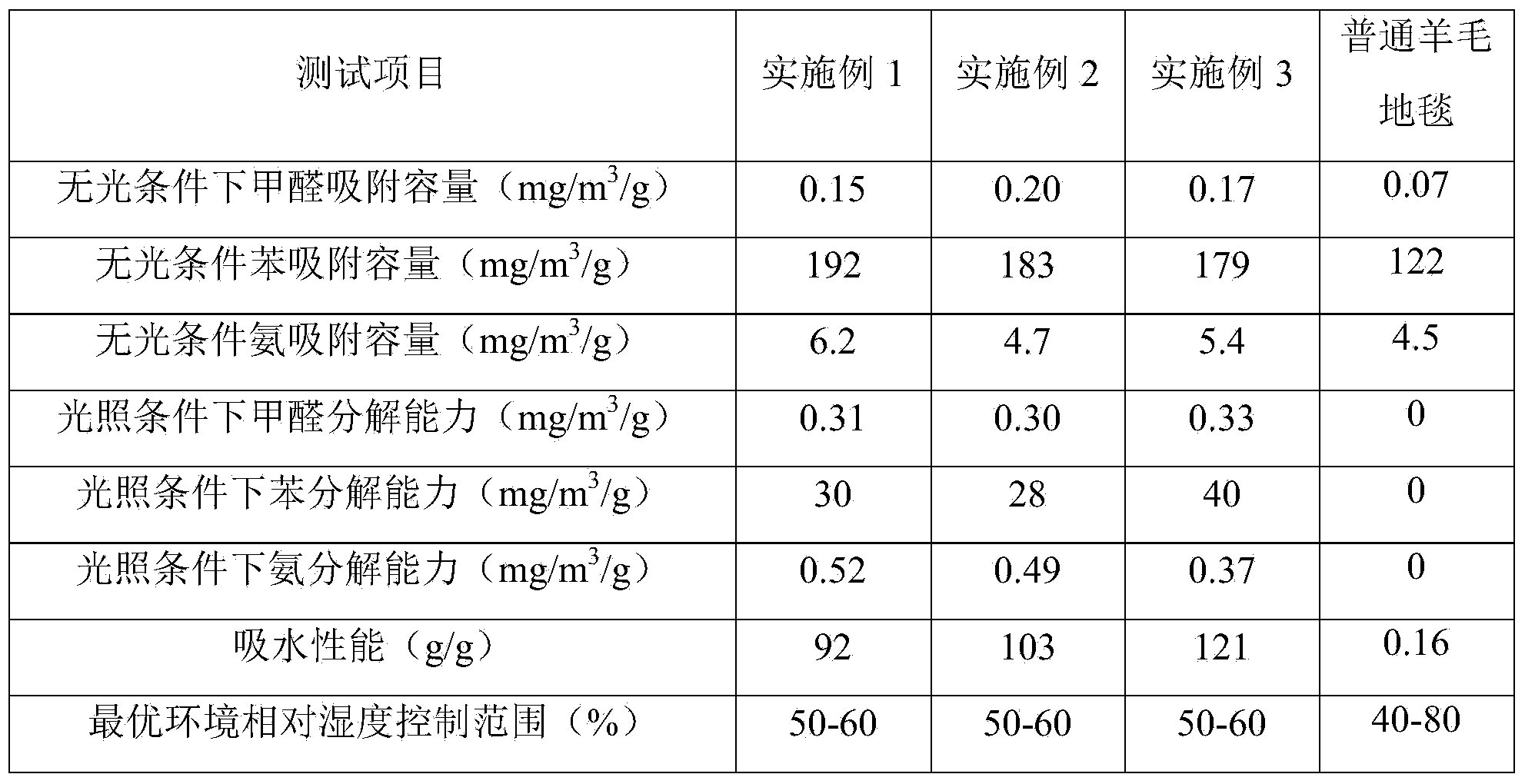

The invention discloses a method for preparing photocatalysis self-cleaning nanometer fiber felt. The method includes the steps that nanometer titania powder, nanometer diatom ooze powder and granules are evenly mixed and then placed in an extruder, and a mixture is extruded out at a working temperature ranging from 80 DEG C to 240 DEG C of the extruder and is cut into photocatalysis self-cleaning master batches; the photocatalysis self-cleaning master batches are added into the granules, the photocatalysis self-cleaning master batches and the granules are evenly mixed and then dissolved in an organic solvent, a mixture is stirred at an indoor temperature until complete dissolving is achieved, and then a spinning solution is prepared, wherein the concentration of solid matter ranges from 50g / L to 100g / L; electrostatic spinning is conducted through the spinning solution, and then a photocatalysis self-cleaning nanometer fiber layer is acquired; the photocatalysis self-cleaning nanometer fiber felt is acquired through compression molding. The fiber felt prepared through the method has the high specific area, can absorb and effectively decompose organic matter, decompose the peculiar smell produced in daily life, adjust the environment humidity, and can be used as a carpet, textile and garment materials, medical materials and the like.

Owner:NANTONG UNIVERSITY

Smell removing and low-power-consumption food heat preservation box

ActiveCN106892197AEasy to useEasy to storeDomestic cooling apparatusLighting and heating apparatusFood storingEngineering

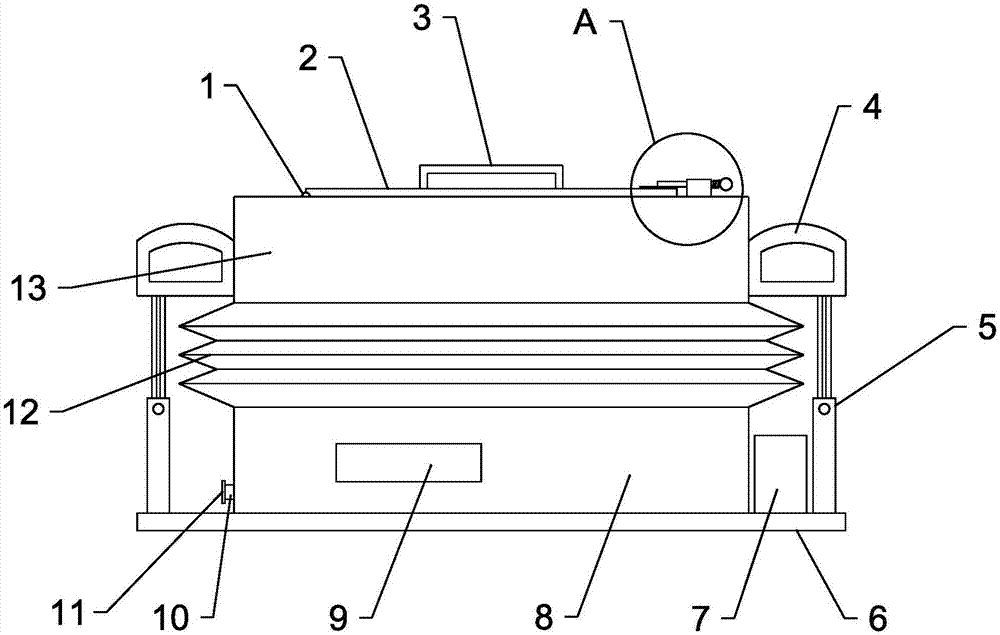

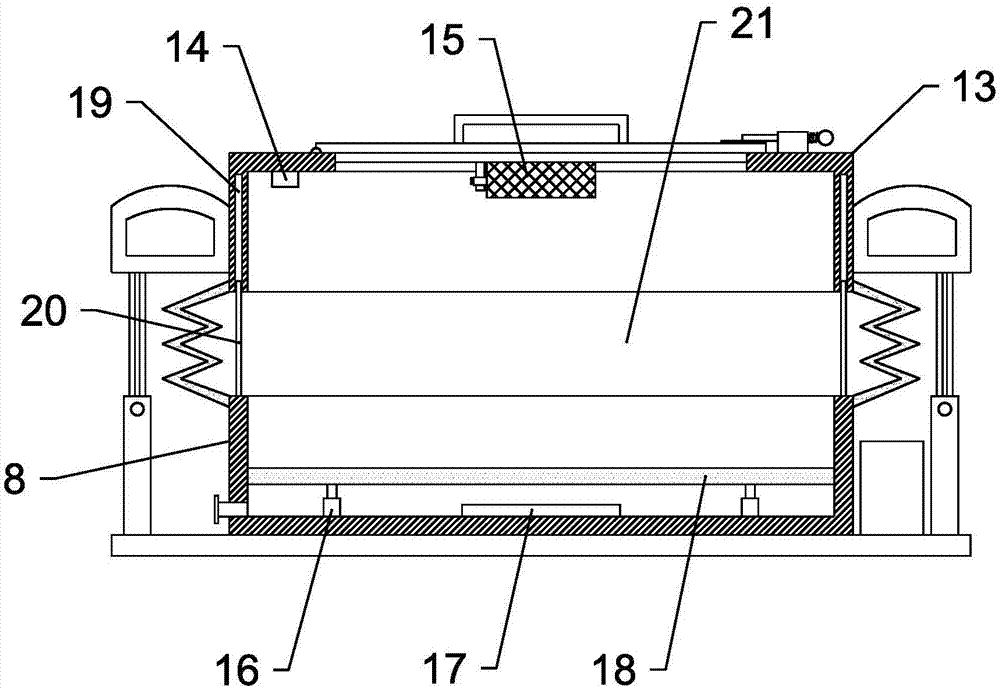

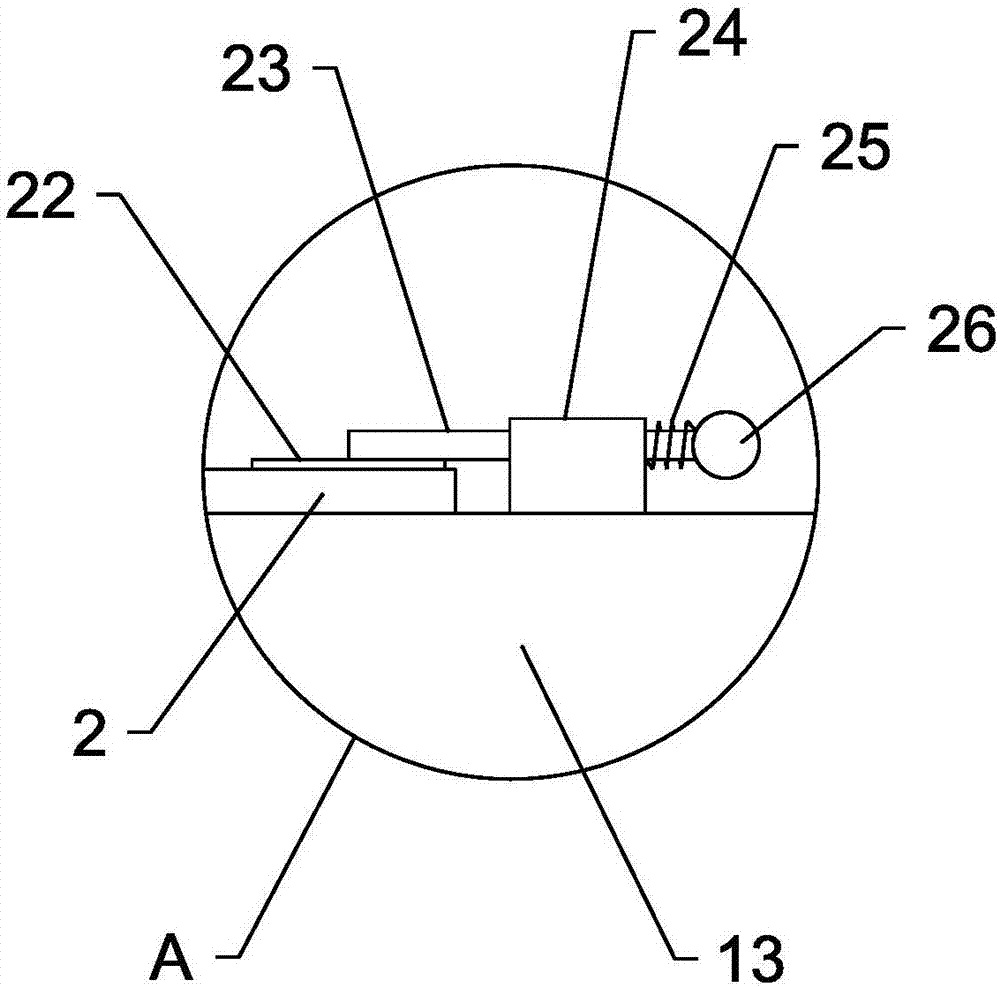

The invention discloses a smell removing and low-power-consumption food heat preservation box. The smell removing and low-power-consumption food heat preservation box comprises a box cover, a base, a lower box body, an elastic corrugated pipe and an upper box body. The upper box body is connected to the upper end of the elastic corrugated pipe. The lower box body is connected to the lower end of the elastic corrugated pipe. The base is further arranged at the bottom of the lower box body. Handles are fixedly arranged on the left side and the right side of the upper box body. Adjustable telescopic rods are fixedly arranged on the lower sides of the handles. The lower ends of the adjustable telescopic rods are fixed to the base. The box cover is arranged at the position of a top opening of the upper box body in a matched manner. A smell removing box is further arranged on the inner top of the box cover. A net-shaped support plate is further arranged at the lower portion of the inner side of the lower box body. A plurality of elastic telescopic rods are arranged on the outer side of the bottom of the net-shaped support plate. A heating block is further arranged at the inner bottom of the lower box body. The base is further provided with a power source. The smell removing and low-power-consumption food heat preservation box is convenient to use, the food storing and heat preservation effects are good, energy consumption is little, peculiar smells can be effectively removed, and the smell removing and low-power-consumption food heat preservation box is convenient to apply and popularize.

Owner:YANGZHOU HONGXIN LINE EQUIP

Environmentally-friendly biomass granule fuel

The invention discloses an environmentally-friendly biomass granule fuel. The environmentally-friendly biomass granule fuel comprises sawdust, crop straw, anthracite smalls, sludge garbage, tea leaf residues, rice hull powder, attapulgite clay, montmorillonite and red mud. According to the environmentally-friendly biomass granule fuel, treatment of the sludge garbage is more environmentally friendly and economical, and the cost of the environmentally-friendly biomass granule fuel is low; compared with biomass granule fuels of the same type which are not compatible with the sludge garbage, theenvironmentally-friendly biomass granule fuel has higher heat value; moreover, the environmentally-friendly biomass granule fuel overcomes the phenomenon of slag-bonding, and discharging of harmful air is greatly reduced.

Owner:安徽盛昌生物能源科技开发有限公司

Packaging material

InactiveCN107554028AImprove securityImprove tear resistanceFlexible coversWrappersTear resistancePolymer

The invention discloses a packaging material. The packaging material comprises a quakeproof layer, an adsorption layer and a base material layer from inside to outside sequentially, wherein the outerside of the base material layer is covered with a PET film, the adsorption layer comprises an adsorbent prepared from a high-molecular polymer material, the quakeproof layer is prepared from a flexible foaming material, and self-adhesive glue is applied to the inner side of the quakeproof layer; the base material layer serves as a support of the packaging material, the PET film can effectively resist water, the quakeproof layer has a good buffer effect and protects fragile goods, the adsorption layer can adsorb peculiar smell of the goods, the self-adhesive glue is applied to the foaming material and can permeate into the foaming material, the quakeproof layer can be torn if a stealer opens the packaging material, and stealing evidence is left. The packaging material is non-toxic, odorless, good in safety, high in buffer resistance strength, good in tear resistance and waterproof effect and capable of effectively removing peculiar smell and preventing stealing and quake and facilitatespackaging of the goods.

Owner:SUZHOU ANTEK INDAL

Environmentally-friendly floor material and preparation method thereof

The invention discloses an environmentally-friendly floor material and a preparation method thereof and relates to the field of floor materials. The environmentally-friendly floor material comprises,by weight, 30-40 parts of waste and old polyvinyl chloride foam, 15-22 parts of waste phenolic foam, 22-28 parts of polylactic acid, 8-15 parts of polycaprolactone, 5-10 parts of castor oil, 8-15 parts of wood chip powder, 15-20 parts of waste and old glass particles, 4-9 parts of nano-zinc oxide, 8-15 parts of nano-silica, 10-18 parts of glass fibers, 8-15 parts of modified montmorillonite powder, 6-12 parts of bamboo charcoal powder, 3-7 parts of polyethylene wax and 1.5-3.5 parts of a silane coupling agent. The environmentally-friendly floor material utilizes waste plastic and waste glass.Through combination of the wastes and other components, the environmentally-friendly floor material has good strength, flexural and compressive resistance and flame retardancy, solves the problems ofspace occupation and recycling of wastes, reduces a production cost and is environmentally friendly.

Owner:HEFEI SHANGQIANG ELECTRIC TECH CO LTD

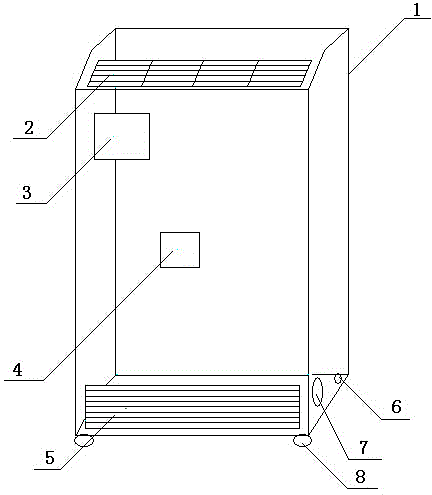

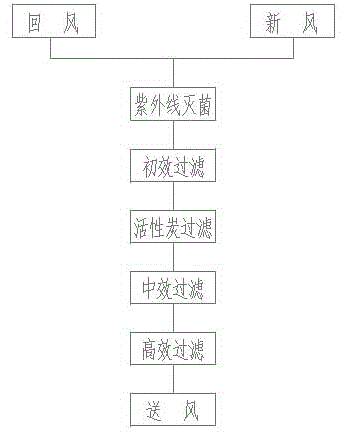

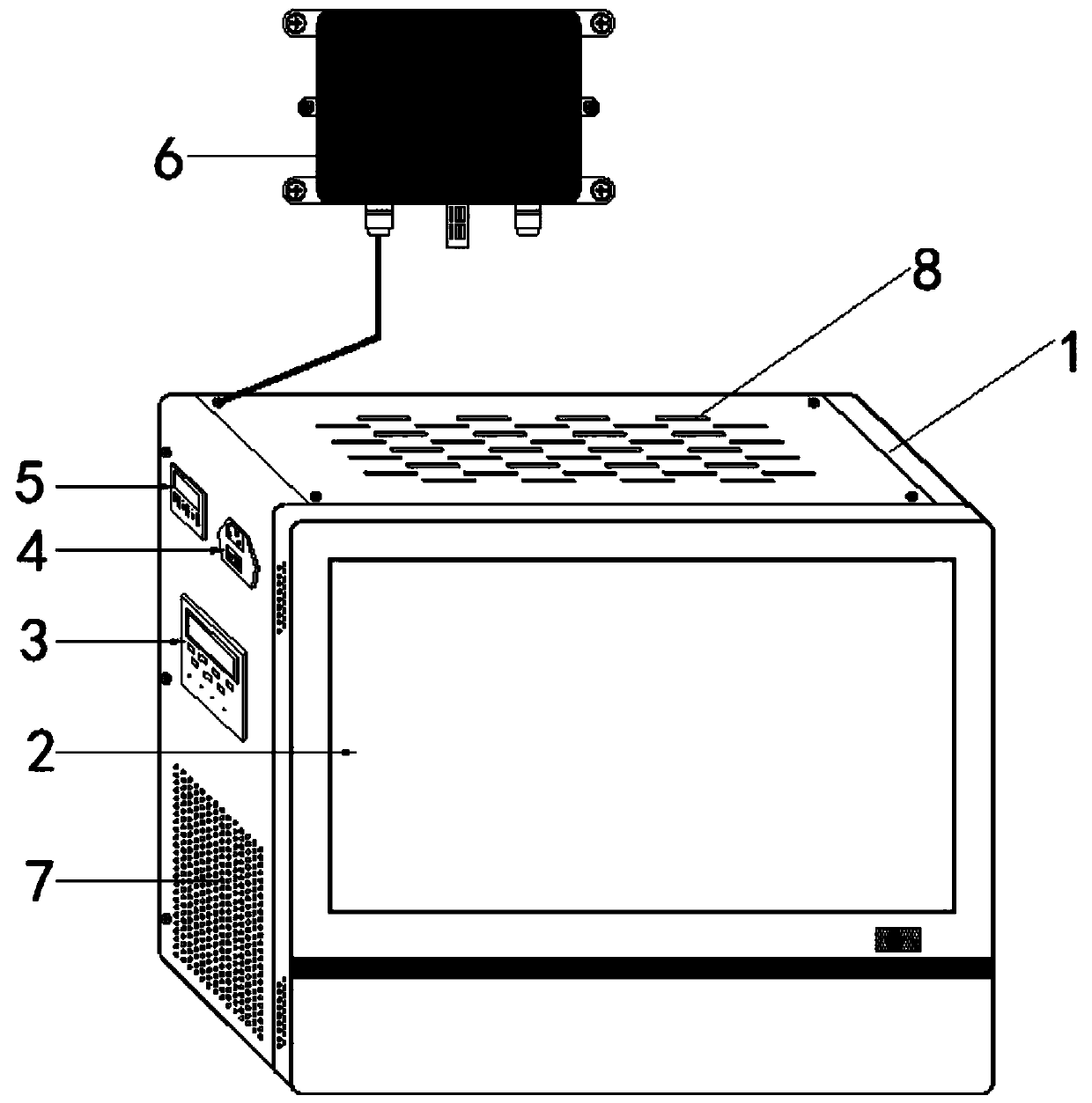

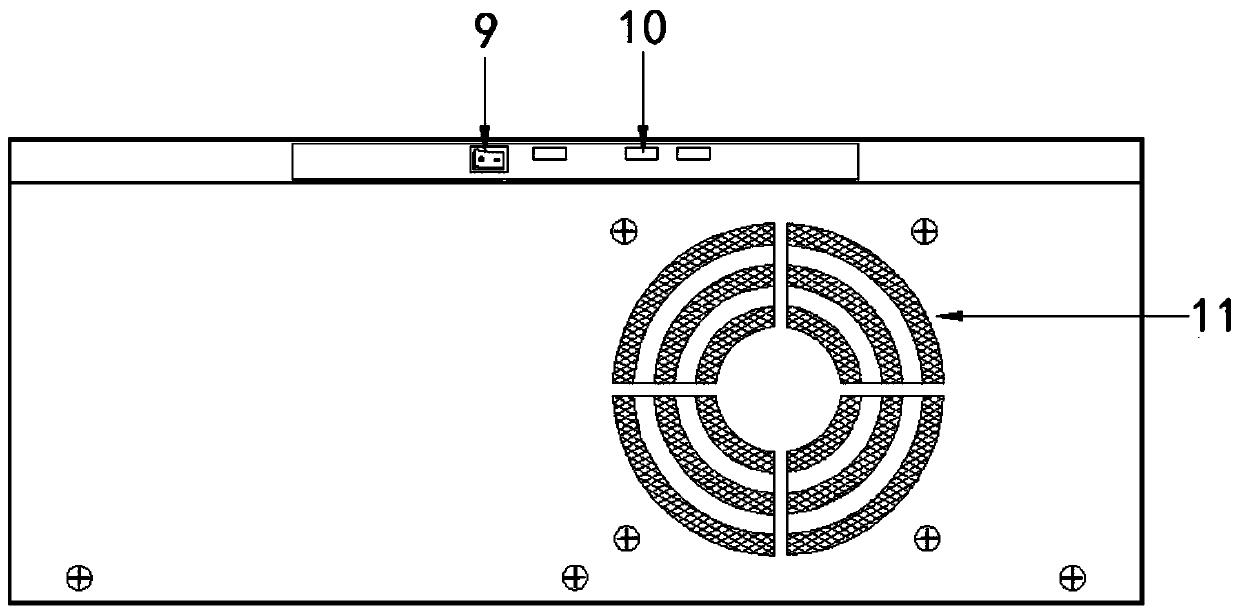

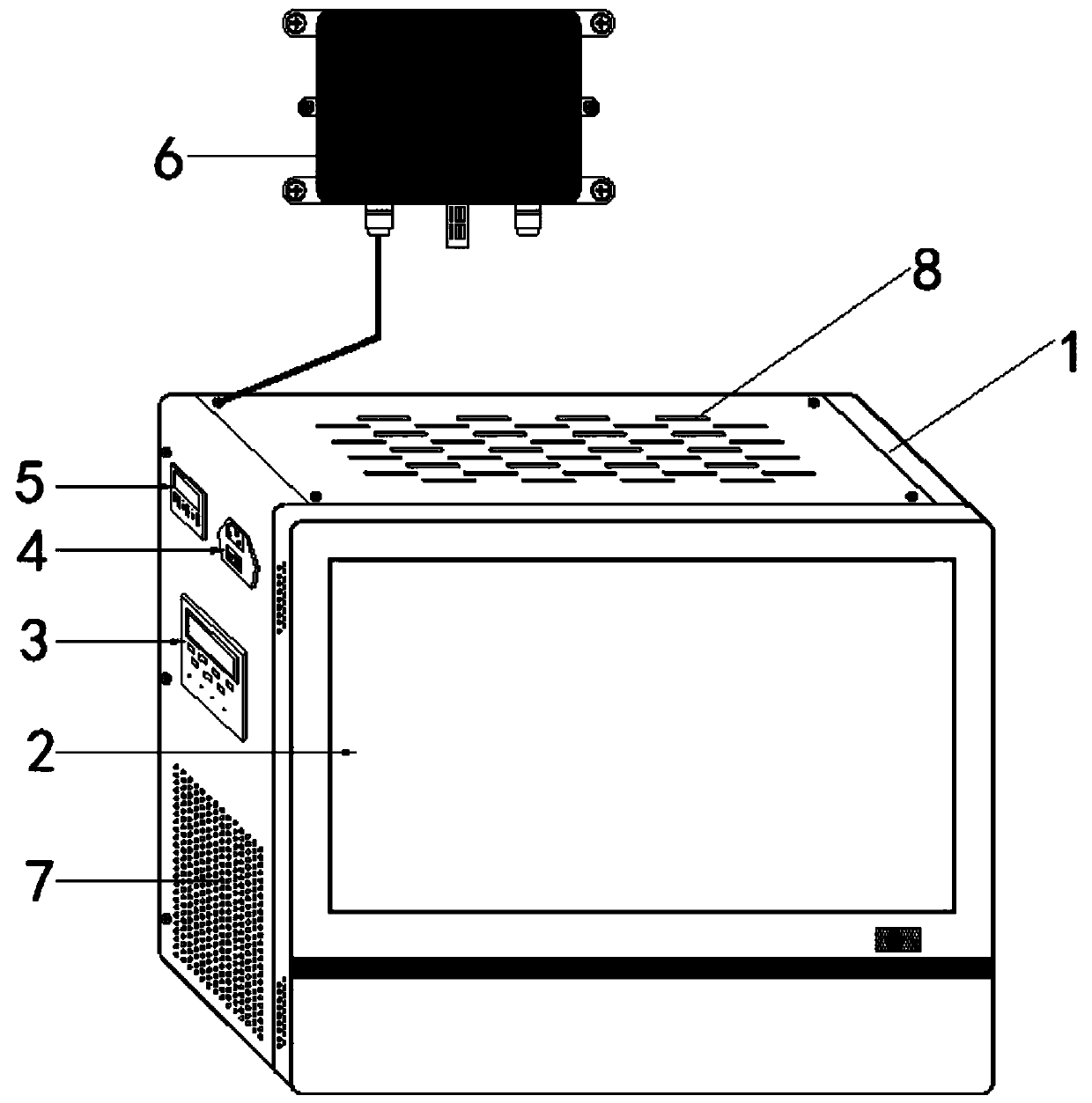

Air sterilizing and purifying system

InactiveCN104406238ASimple structureEasy to installMechanical apparatusLighting and heating apparatusLiquid-crystal displayActivated carbon filtration

The invention discloses an air sterilizing and purifying system. The system comprises a shell; an air outlet is formed in the top of the shell; a liquid crystal display control screen and a probe detecting hole are arranged on the front surface of the shell; an air returning hole is formed below the probe detecting hole; an ultraviolet sterilizing lamp is arranged at the bottom end of the inner side of the shell; a primary filter, a medium-efficiency filter and a high-efficiency filter are sequentially arranged over the ultraviolet sterilizing lamp; an active carbon filter is arranged between the primary filter and the medium-efficiency filter; a supporting cross bar is arranged between the medium-efficiency filter and the high-efficiency filter; a fan bracket is arranged on the supporting cross bar and used for fixing a fan. The air sterilizing and purifying system disclosed by the invention is simple in structure, convenient to install, capable of disinfecting and sterilizing air, filtering and removing dust, also capable of effectively removing peculiar smells, low in electric energy usage, low in noise and convenient to move.

Owner:汤坤林

Grapefruit fragrant washing liquid

The invention discloses a grapefruit fragrant washing liquid, which comprises the following components in weight percent: 10-15% of a grapefruit peel extract, 5-10% of a grapefruit flower extract, 3-6% of glycerol, 8-12% of an emulsifier, 2-5% of a non-ionic surface active agent, 2-5% of jojoba oil, 1-3% of olive oil, 0.5-1% of a daily use essence, 0.5-1% of a pigment, and the balance of distilled water. The product uses the grapefruit peel as the main raw material, can effectively remove the odor and efficiently clean clothes dirt, is gentle and harmless to the hand, and also has the characteristics of sterilization, bacteriostasis, pleasant fragrance, and lasting fragrance.

Owner:陆阳林

Carpet bacterium-removing deodorant

The invention relates to carpet deodorant and a preparation method thereof. The carpet deodorant is mainly used for removing bacteria and odor of various carpets. The carpet deodorant has the following advantages that effects of removing the bacteria and preventing bacteria are obvious, various odors caused by bacteria on the carpets can be effectively removed, the long-acting antibacterial activity is realized, the carpets are not required to be washed after the carpet deodorant is used, carpet fabric fiber is not influenced, and the carpet deodorant does not corrode or irritate skin and does not have residue on the skin. The carpet deodorant comprises the following selected formula (components in percentage by weight) 3 to 6 percent of carboxymethyl chitosan, 6 to 10 percent of algal polysaccharides, 10 to 16 percent of marine organism lysozyme, and the balance of pure water to 100 percent.

Owner:QINGDAO HIFUN MARINE BIOLOGICAL TECH

Natural refrigerator odor removal bactericide

InactiveCN106561729AFresh tasteEasy to useBiocideMetabolism disorderActivated carbonBatch production

The invention belongs to the field of daily supplies, and particularly relates to a natural refrigerator odor removal bactericide. The natural refrigerator odor removal bactericide is characterized by being composed of, by mass, 50-70 parts of pericarp particles, 3-8 parts of sophora flavescens powder, 2-5 parts of thymol, 3-8 parts of a rosa multiflora extraction solution, 5-10 parts of a cactus extraction solution, 5-10 parts of a monstera deliciosa extraction solution, 10-15 parts of bamboo charcoal, 15-25 parts of activated carbon and 5-10 parts of medical stone. The required raw materials all come from frequently-seen natural crops, a manufacture method is simple, no complex processes are needed, sterilization and odor removal can be conducted in a refrigerator, smell in the refrigerator can be kept naturally fragrant, meanwhile, the safety requirement for food in the refrigerator is also met, it is avoided that toxicity of the bactericide is too large, and the natural refrigerator odor removal bactericide is suitable for batch production and wide application.

Owner:GUANGXI UNIV

Deodorant special for livestock and poultry breeding excrement and preparation method thereof

The invention discloses a deodorant special for livestock and poultry breeding excrement. The deodorant is prepared from the following raw materials by weight: 35-40 parts of corn flour, 5-9 parts of cyclodextrin, 8-12 parts of soybean meal, 2-3 parts of sodium chloride, 6-10 parts of lotus leaf, 3-5 parts of artemisia argyi, 4-7 parts of purslane, 2-3 parts of an inoculant, 8-12 parts of modified vermiculite powder, 5-8 parts of alum, and 24-28 parts of plant ash. The invention also discloses a preparation method of the deodorant special for livestock and poultry breeding excrement. The deodorant prepared by the method provided by the invention can effectively remove the odor of livestock and poultry breeding excrement, avoids the adverse effect of malodorous gas on the health of people on the scene and around, is conducive to maintaining the surrounding environment of breed farms, and has strong practicability.

Owner:HUNAN VAUBAN ENVIRONMENTAL PROTECTION TECH CO LTD

Essential oil air purifier

The invention discloses an essential oil air purifier which comprises the following components in parts by weight: 2-2.5 parts of dipropylene glycol monomethyl ether, 2-2.5 parts of dipropylene glycol, 0.1-1 part of ethyl alcohol and 4-6 parts of plant essential oil. The preparation method comprises the following steps: a) distilling and purifying to obtain plant essential oil; b) weighing the plant essential oil and ethyl alcohol in parts by weight, adding the plant essential oil and ethyl alcohol into a mixing tank, stirring the mixing tank on a stirrer for 2-3 minutes, adding dipropylene glycol monomethyl ether and dipropylene glycol while stirring, further stirring for 2-3 minutes, taking down the mixing tank, placing in a shady and cool place, and standing, thereby obtaining the purifier. According to the invention, the natural plant essential oil serves as a raw material, so that odor can be effectively removed; the added dipropylene glycol monomethyl ether is mixed with the dipropylene glycol and ethyl alcohol, and the original essential oil is diluted, so that the aroma is soft and pleasant. During use, pipeline inner wall adhesion is reduced, and the loss is reduced. Moreover, the purifier disclosed by the invention is good in odor removal effect, excellent in water solubility, low in adhesive capacity, wide in applicability and high in diffusivity and volatility.

Owner:彭博

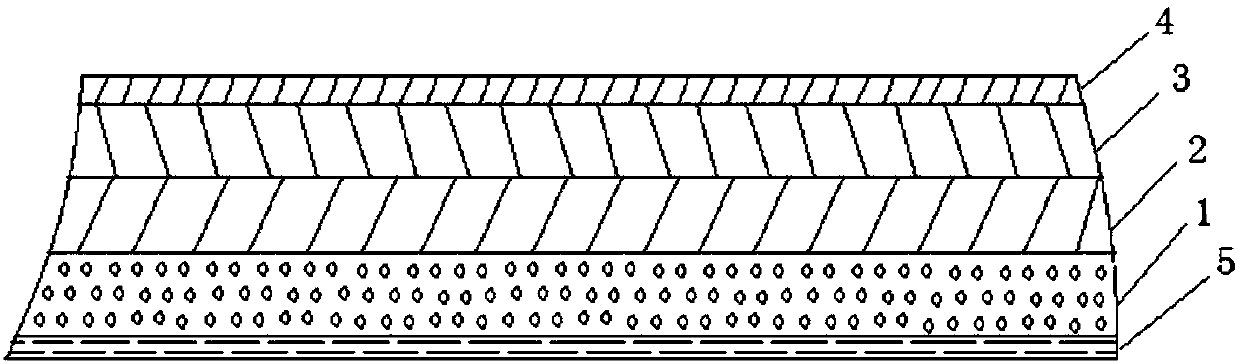

Novel 3D (three-dimensional) mattress

The invention relates to a novel 3D (three-dimensional) mattress. The novel 3D mattress comprises a mattress, wherein the mattress is of a three-dimensional structure, the intermediate part is formed by superimposing a fiber yarn cushioning fabric with strong air permeability and a 3D function, and fiber yarns are mutually intersected for supporting. The fiber yarns of the mattress disclosed by the invention are intersected for supporting, so that the mattress has the advantages of high elasticity, high density, no springs, no latex and no sponge, as well as air permeability and rebound resilience, which are beyond comparison with traditional materials. Simultaneously, the novel 3D mattress is environment-friendly, non-toxic, less prone to being moisturized and breeding bacteria, mildew-proof and easy to clean, and can be used for effectively removing the peculiar smell, thereby being a perfect substitute for traditional sponge mattresses and red elm mattresses.. The novel 3D mattress disclosed by the invention has the advantages of simple structure, convenience in manufacturing, environmental friendliness and no toxicity.

Owner:JIANGSU TEVEL

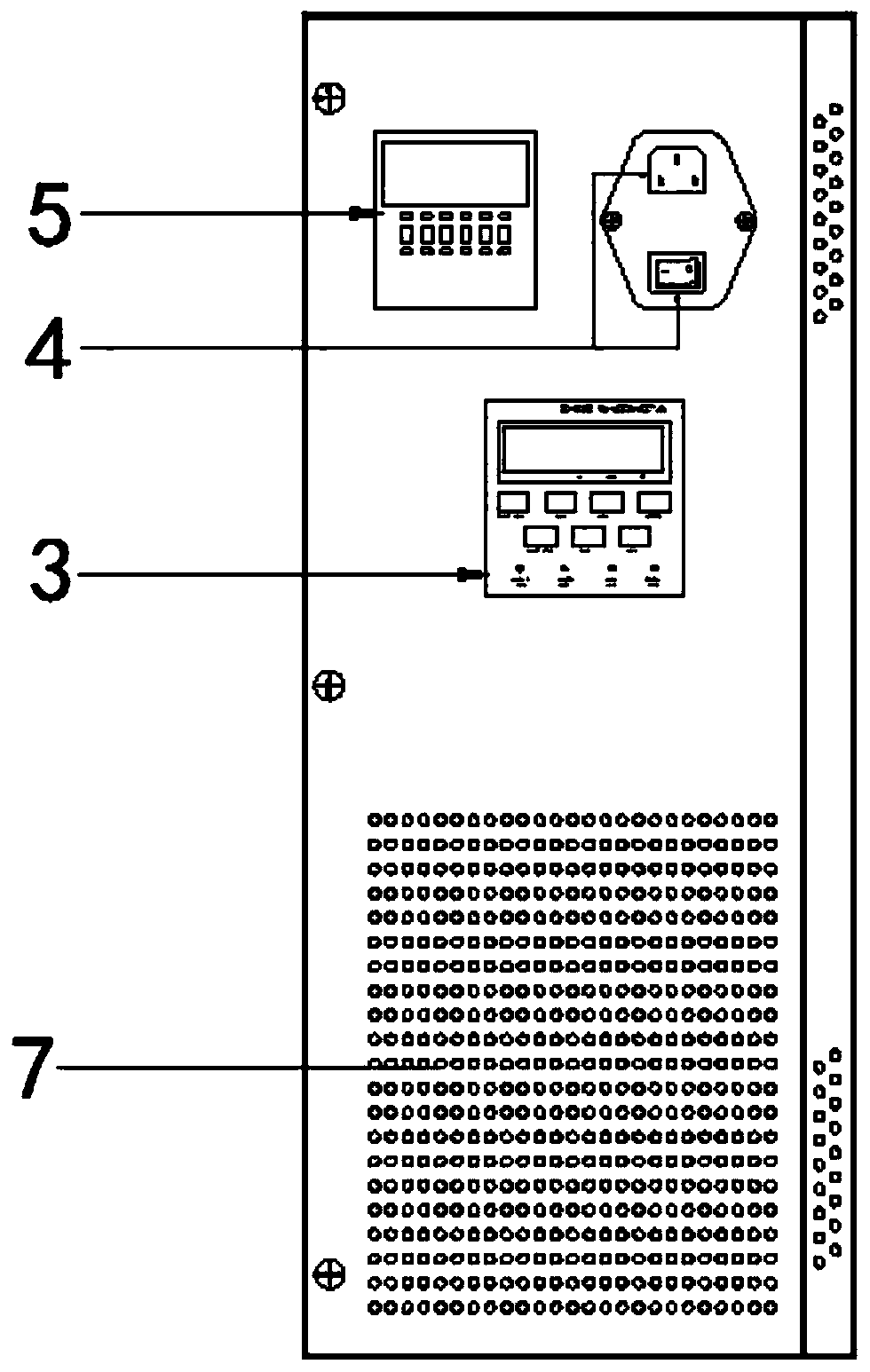

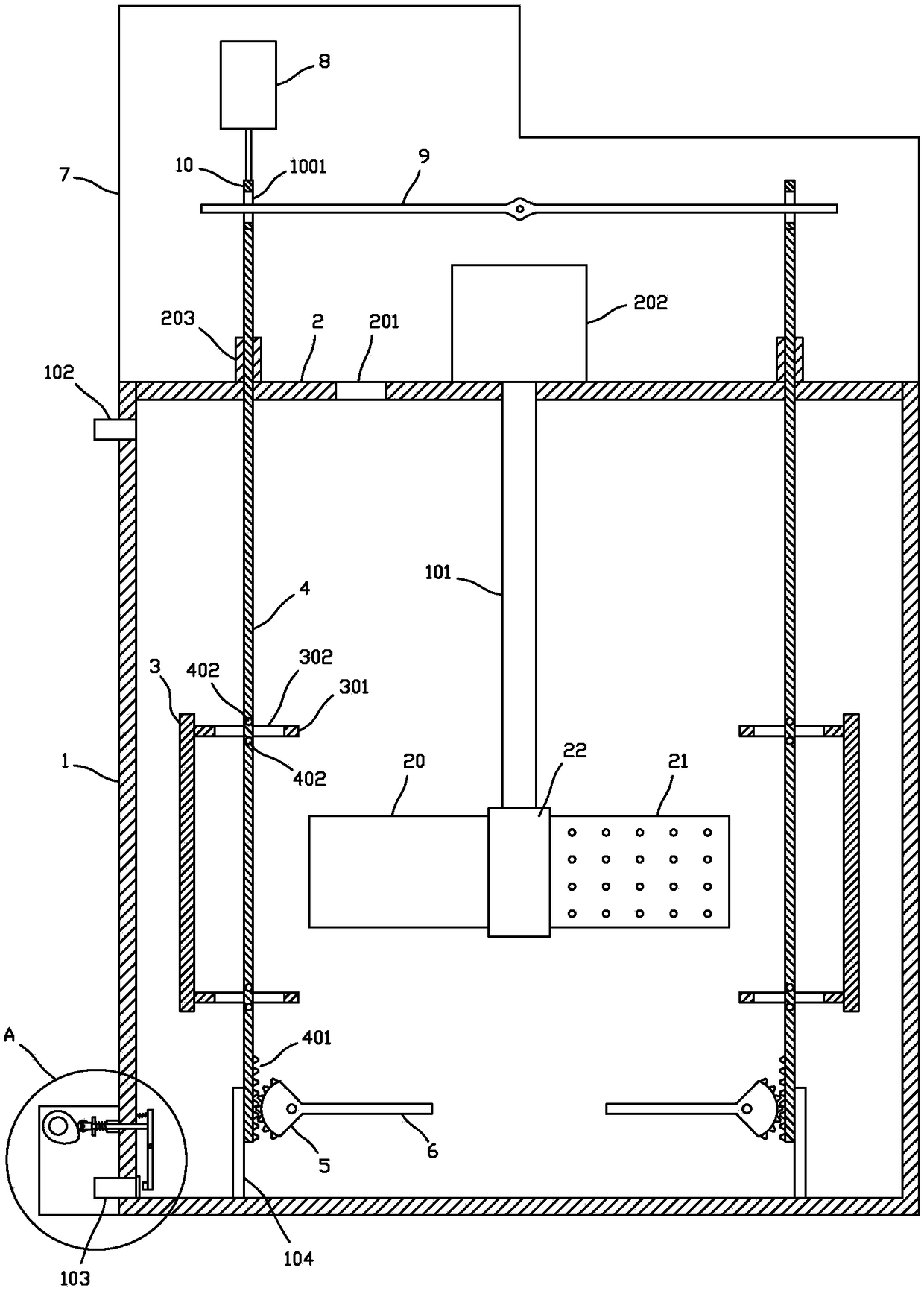

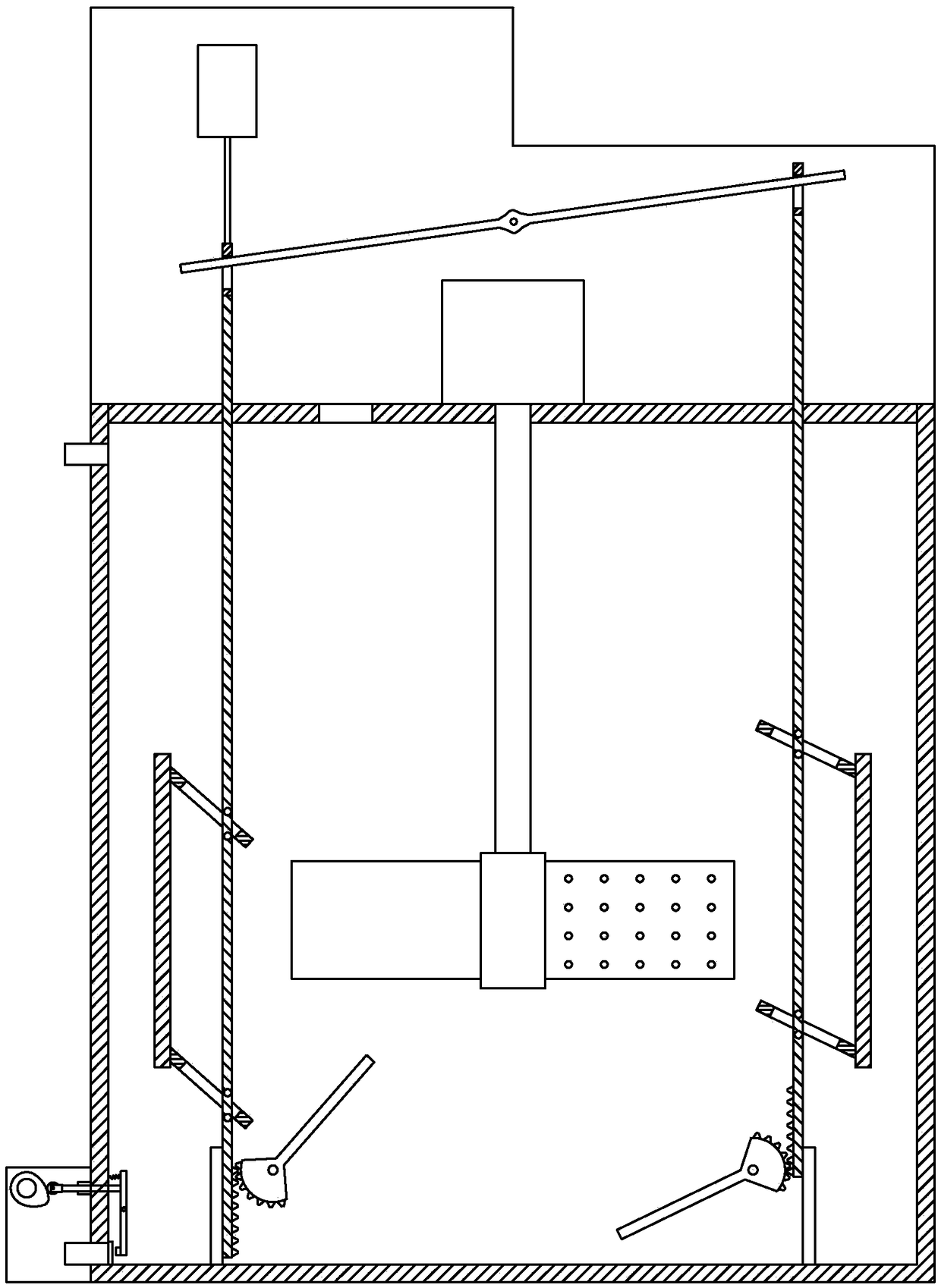

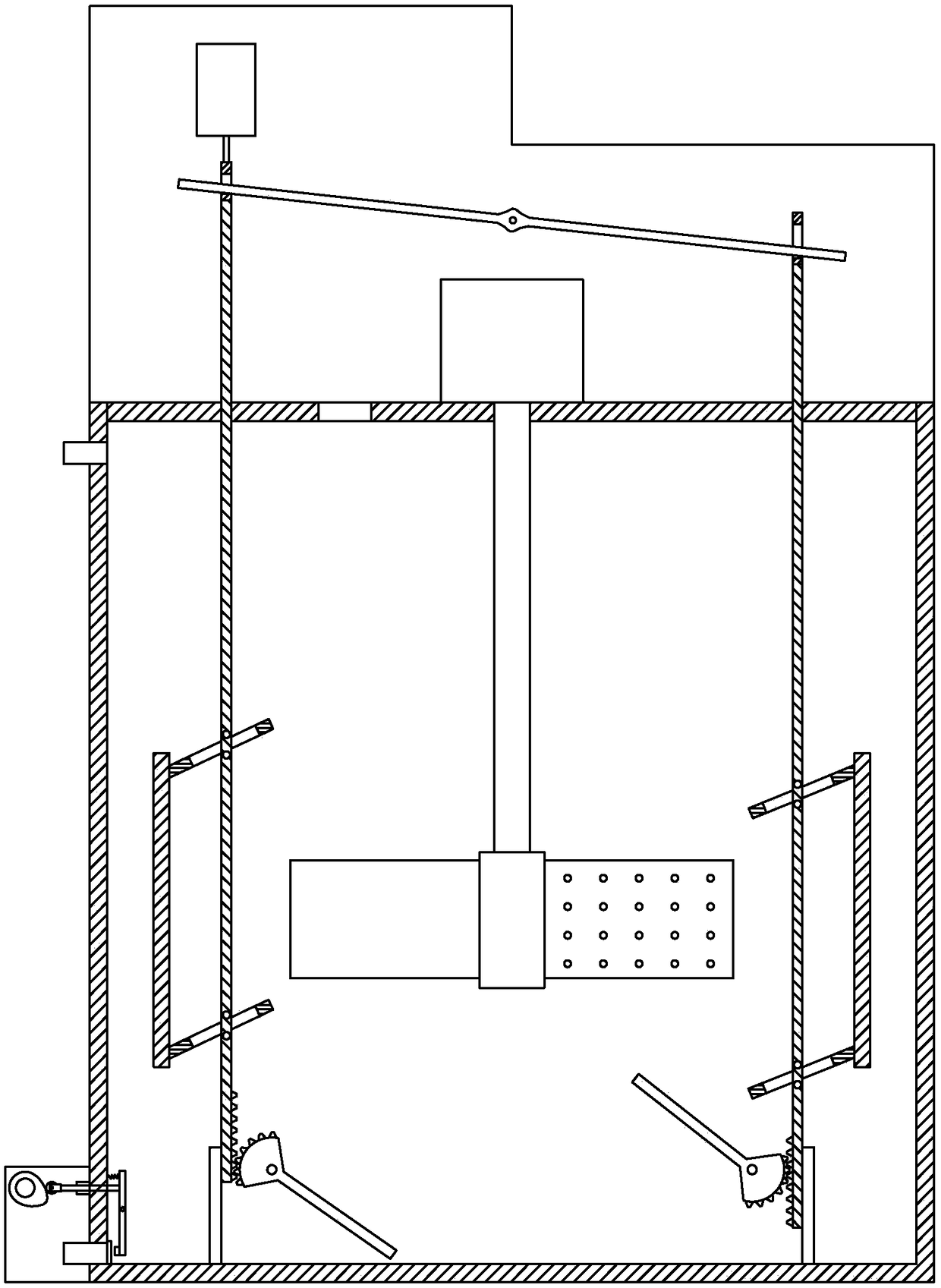

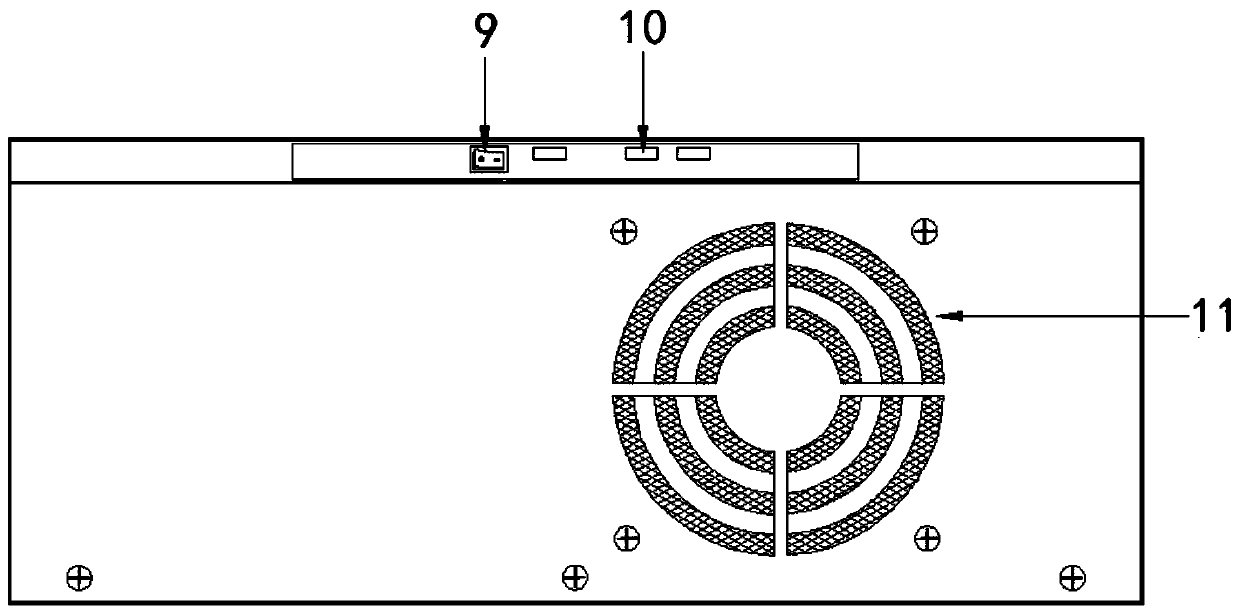

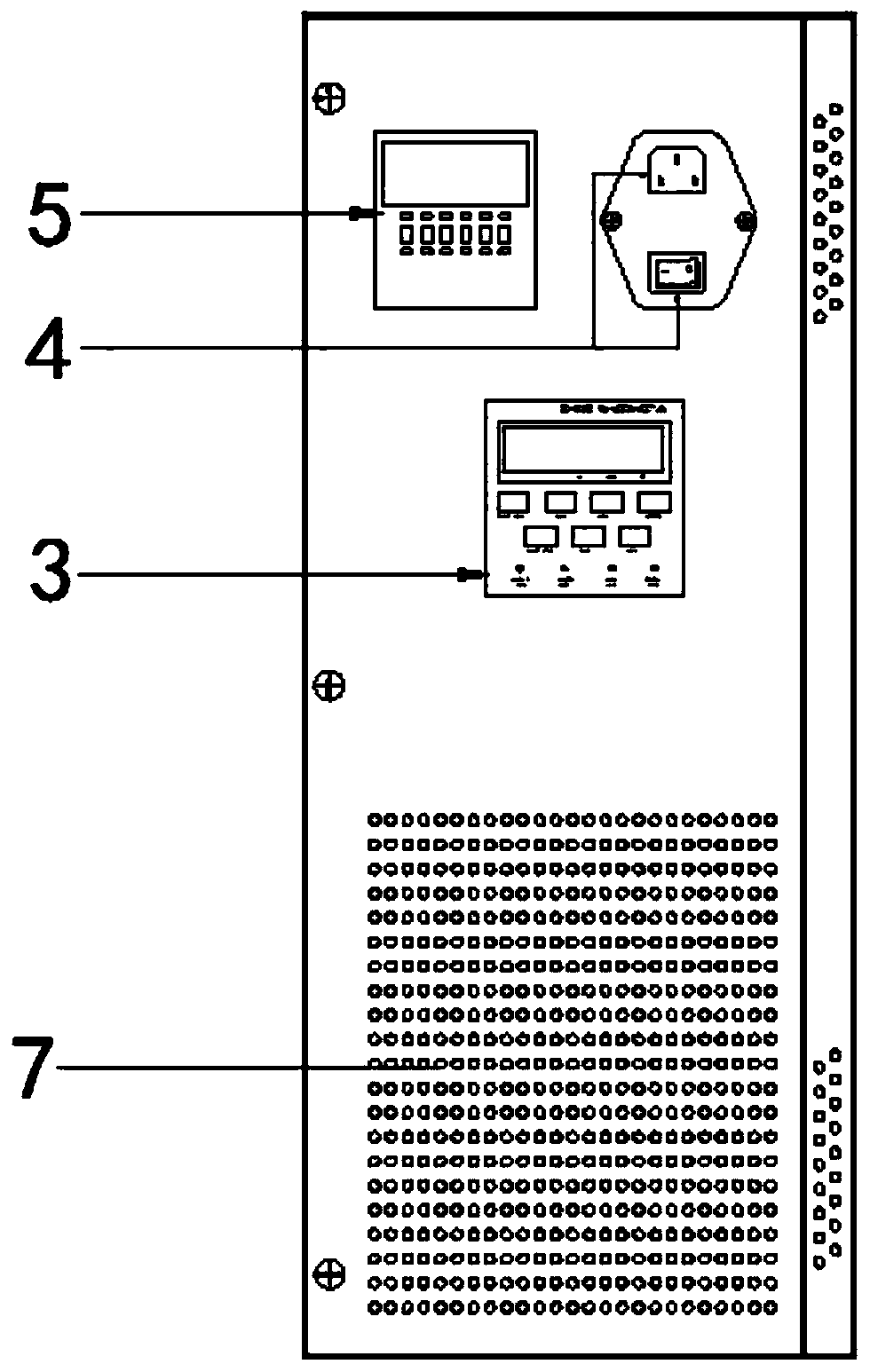

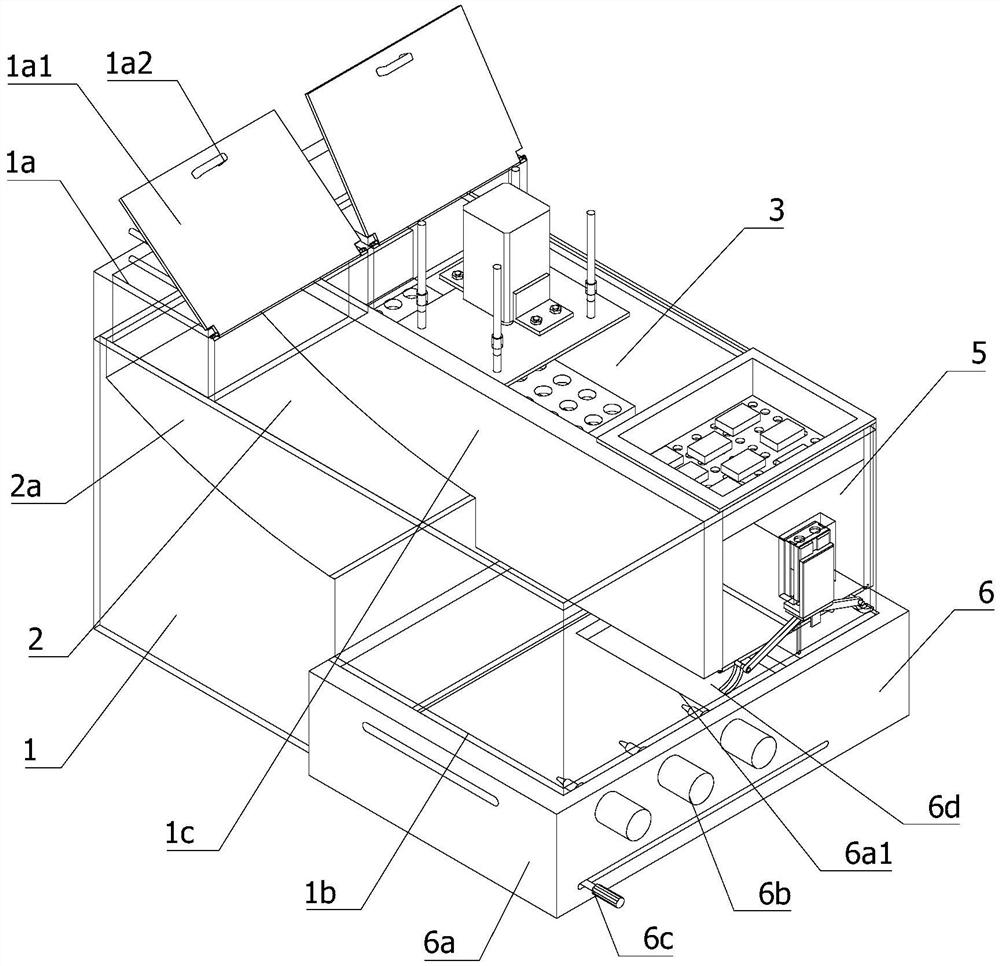

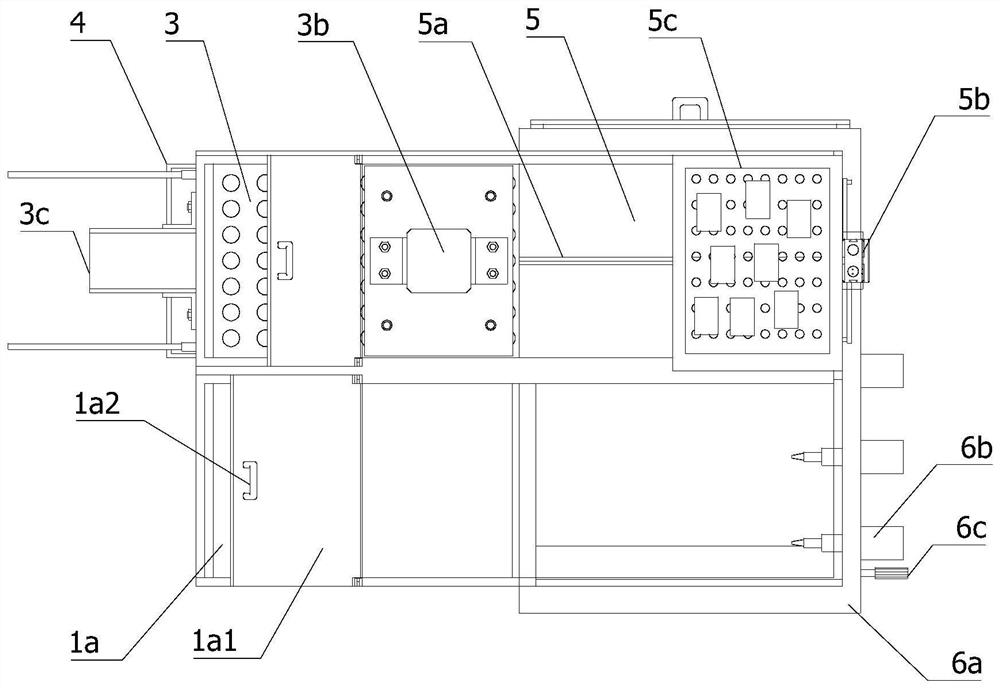

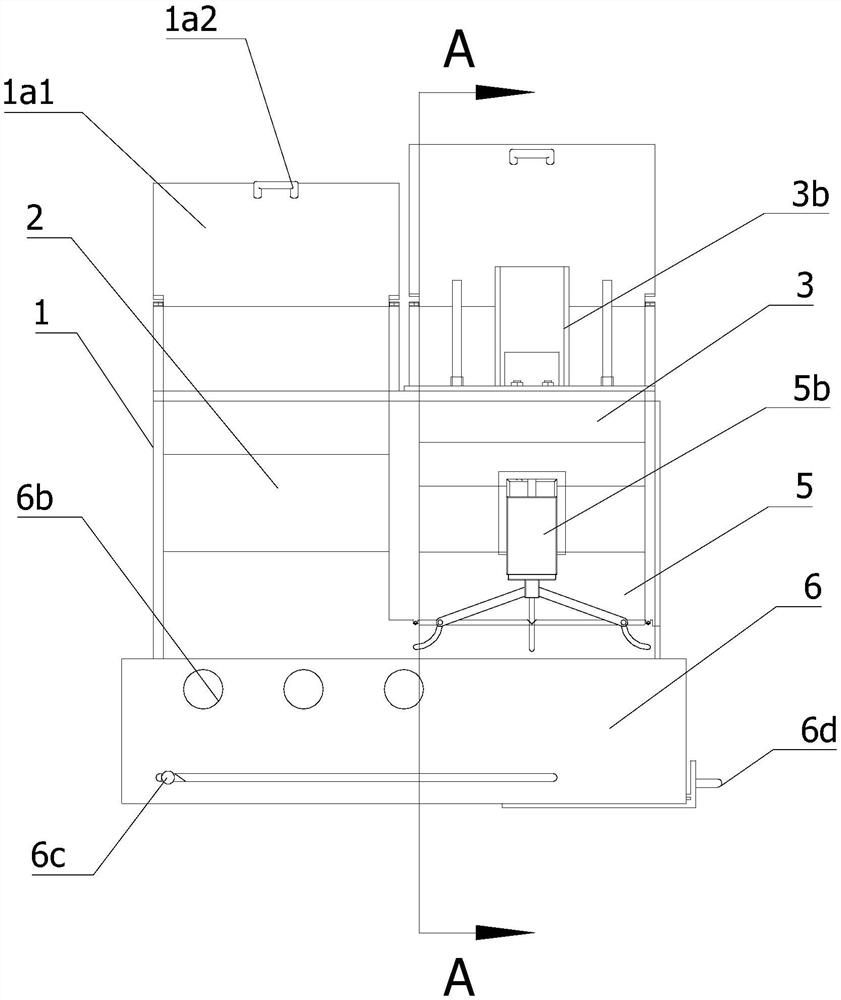

Internet of Things public washroom deodorization system

PendingCN110616783AGood deodorizing effectVersatileLavatory sanitoryArticle advertisingInternet of ThingsControl equipment

An Internet of Things public washroom deodorization system is characterized by comprising a main body and a detection sensor; the detection sensor is connected with a controller arranged in the main body through a wire, the detection sensor transmits a detection signal to the controller, and the controller controls equipment to work for deodorization; the controller is connected with a communication module and performs information interaction with a remote control terminal through the communication module; the controller is further connected with an ultraviolet air purification module, a fragrance diffusion module and the control end of a control panel which are arranged in the main body; the controller controls the ultraviolet air purification module and the fragrance diffusion module towork through detection information of the detection sensor. The system has the beneficial effects that the detection data of the detection sensor can be remotely checked in real time, so that an operator can conveniently and remotely control equipment deodorization and advertisement putting; air aroma enhancement and deodorization are combined with sterilization and deodorization from the source,the deodorization effect is better, and the content of odor in air is restrained from the source. Complete functions are provided.

Owner:深圳市东荣环保科技有限公司

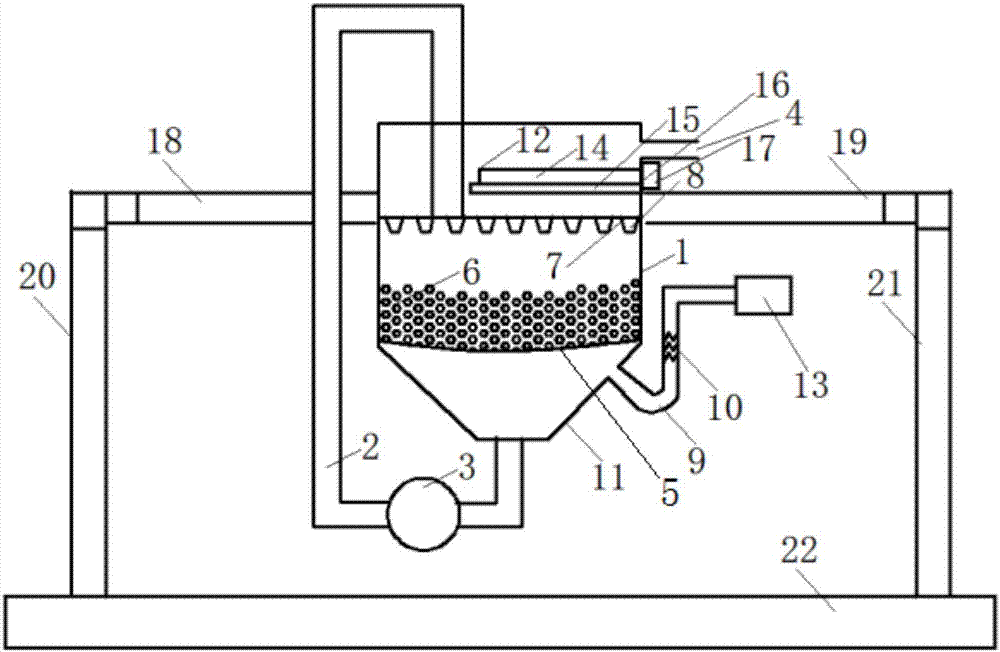

Sewage purification treatment device

InactiveCN108862732AImprove purification efficiencyWell mixedSpecific water treatment objectivesTreatment involving filtrationEngineeringSewage

The invention discloses a sewage purification treatment device which comprises a barrel body, wherein a stirring paddle assembly is arranged in the barrel body, first flat plates are respectively arranged on the two sides of the stirring paddle assembly, two second flat plates are arranged below the stirring paddle assembly, the stirring paddle assembly can be used for stirring sewage to make thesewage rotate and flow in the horizontal direction, the first flat plates and the second flat plates can be used for stirring the sewage in the up-down direction, and sewage treatment chemicals can bequickly and evenly mixed with upper-layer sewage and lower-layer sewage. The sewage treatment chemicals used by the sewage purification treatment device disclosed by the invention in sewage purification comprise a flocculating agent and a deodorizing agent; the deodorizing agent is prepared from the following substances in parts by mass: 15 to 20 parts of bamboo leaf, 10 to 15 parts of wormwood,4 to 8 parts of herba menthae and 4 to 8 parts of cortex cinnamomi; the deodorizing agent in the sewage purification treatment device disclosed by the invention is prepared from natural plants and hasthe advantages of health, environmental friendliness and very good deodorizing effect; the sewage deodorizing effect can be achieved by adding a small amount of the deodorizing agent into the sewage.

Owner:俞松炜

Equipment and method for producing chili oil by using equipment

InactiveCN106147991ARealize automated productionSave manpower and material resourcesFatty-oils/fats productionEdible oils/fatsGARLIC POWDERProcess engineering

The invention discloses equipment and a method for preparing chili oil by using the equipment. The equipment comprises a drying device, a dampening device, a crushing device, an extracting device and a separating device. The method comprises the steps of baking chilies, carrying out crushing, carrying out dampening, carrying out extracting and carrying out separating. According to the equipment and the method, through effectively connecting the drying device, the dampening device, the crushing device, the extracting device and the separating device, automated production is basically achieved, human and material resources are greatly saved, and the production cost is reduced greatly. Through mixing pungent litse fruit powder, garlic powder, tea leaf meal, ginger powder and chili powder and carrying out extraction, off odors can be effectively removed from the chili oil, the flavor of the chili oil is improved, and the quality and aroma of the chili oil are improved.

Owner:张杰

Decontamination device aiming to waste gas and method of decontamination device

InactiveCN106975330AEfficient removalEffective odorGas treatmentDispersed particle separationFusion weldingExhaust pipe

The invention discloses a decontamination device aiming to waste gas and a method of the decontamination device. The decontamination device comprises a decontamination tower arranged in a residential quarter; the decontamination tower is internally provided with a plant purification module to enable the waste gas entering the decontamination tower to be purified, is also equipped with a connecting piece and comprises a tower body and a pump pipe with two ends being communicated with the top and the bottom of the tower body respectively; the tower body is also internally provided with the plant purification module; the plant purification module is arranged below an exhaust pipe and above a spraying plate; an air outlet of an air pump is communicated with an air inlet pipe; and an air inlet of the air pump is used for enabling atmosphere to permeate through within a residential quarter range. According to the decontamination device and the method, by combining with the method, the defects that the needs for purifying harmful gas, such as formaldehyde, benzene, ammonia and the like, and peculiar smell in the waste gas which is spread in the residential quarter cannot be met, a fusion welding part is usually damaged by erosion of acid materials in air, and a worker is usually scalded by a welding flux during fusion welding in the prior are effectively prevented.

Owner:北京立道立德科技有限公司

Preparation method of nanometer starch deodorant

The invention discloses a preparation method of a nanometer starch deodorant, comprising the following steps: (1) adding an appropriate amount of starch into a buffer solution, heating in a boiling water bath, and gelatinizing sufficiently to obtain a starch solution; (2) enzymatically hydrolyzing the gelatinized starch solution for a certain time, and then heating to terminate the enzyme activityto obtain product A; 3) centrifuge product A, crystallizing, filter and vacuum drying to obtain nanometer starch particles; and 4) ultrasonic washing the obtained nanometer starch particles to prepare the nanometer starch deodorant. The nano-starch deodorant prepared by the preparation method has the advantages of wide source of raw materials, easy obtaining, low cost, good effect, and can effectively remove peculiar smell, thus being environment-friendly and free from any side effects; and the preparation method of the nanometer starch deodorant has the advantages of mild condition, simple procedure, low cost and environmental protection.

Owner:ANHUI KIWI BIOTECH CO LTD

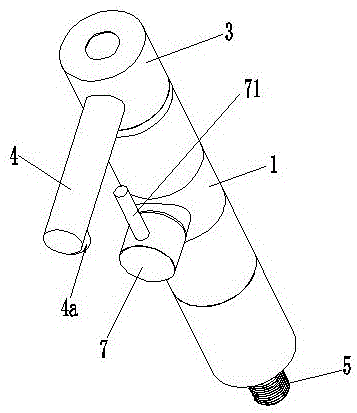

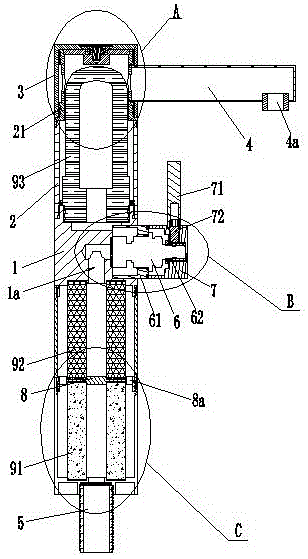

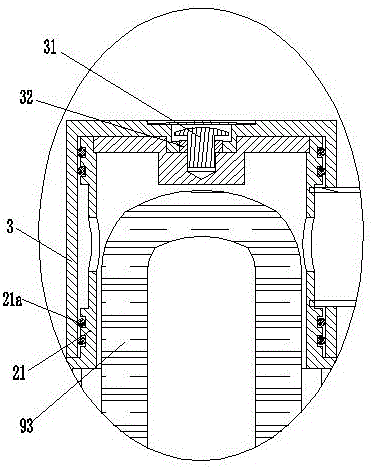

Three-stage filtering water tap

InactiveCN106337959AEffective impuritiesEffective odorOperating means/releasing devices for valvesFiltration separationThree stageAgricultural engineering

The present invention discloses a three stage filter water tap, which comprises a water tap body , on top of which a sleeve is connected; on upper part of which a connecting piece is provided; on casing of the connecting piece a cover lid is provided, which permit the said connecting piece to rotate for fitting; a water outlet tube is connected on the cover lid and a water outlet is provided on the water outlet tube; on the lower part of the water tap body is provided with a water inlet hole and the lower part of the water tap is connected with an inlet tube; the inlet tube is connected with the said water inlet hole;the water inlet hole on the water tap is connected with the water outlet tube through a valve core, on external of which a valve shell is provided; the flower tooth end is provided with a valve core cover; and outside the valve core a hand wheel is provided; and the first-stage filter, the second-stage filter and the third-stage filter in different materials are provided in sequence from bottom up in side the water tap. The present invention has advantages of simple structure, easy to manufacture, the outlet can rotate 360 o and the use of three stage filter structure composed of different filter elements will ensure the safety of use.

Owner:谢裕祖

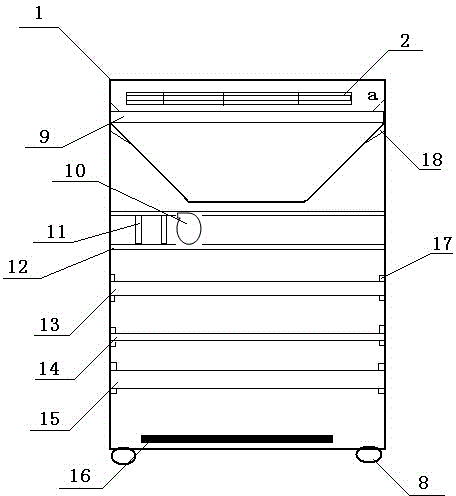

Public washroom deodorizing system

PendingCN110593370AGood deodorizing effectVersatileLavatory sanitoryArticle advertisingControl equipmentEngineering

The invention relates to a public washroom deodorizing system. The public washroom deodorizing system is characterized in that a main body and a detection sensor are included, the detection sensor isconnected to a controller arranged in the main body through a wire, the detection sensor transmits a detection signal to the controller, and the controller controls equipment to work to achieve deodorization; the controller is also connected to an ultraviolet air purification module, a fragrance diffusing module and the control end of a control panel, and the ultraviolet air purification module, the fragrance diffusing module and the control panel are arranged in the main body; and the ultraviolet air purification module includes an ultraviolet air pipe, a lower pipe of the ultraviolet air pipe is internally provided with an exhaust fan, the diameter of an air inlet of the ultraviolet air pipe is larger than the diameter of an air outlet, and the ultraviolet air pipe is arranged at the airinlet. The public washroom deodorizing system has the beneficial effects that air fragrance enhancement and deodorization are combined with sterilization and deodorization from the source, a better deodorizing effect is achieved, and the content of odor in air is suppressed fundamentally. The functions are complete, the system is best used, the system can achieve deodorization effectively, the functions like advertising are also considered, and the device is used as much as possible.

Owner:深圳市东荣环保科技有限公司

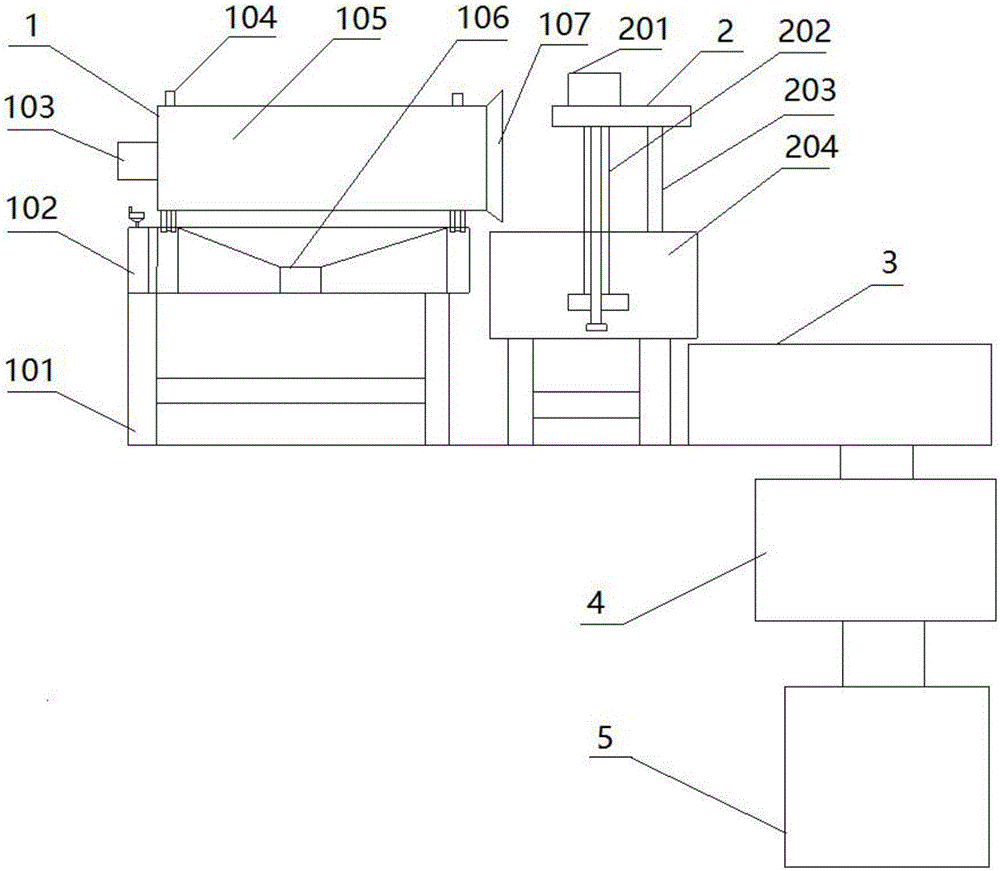

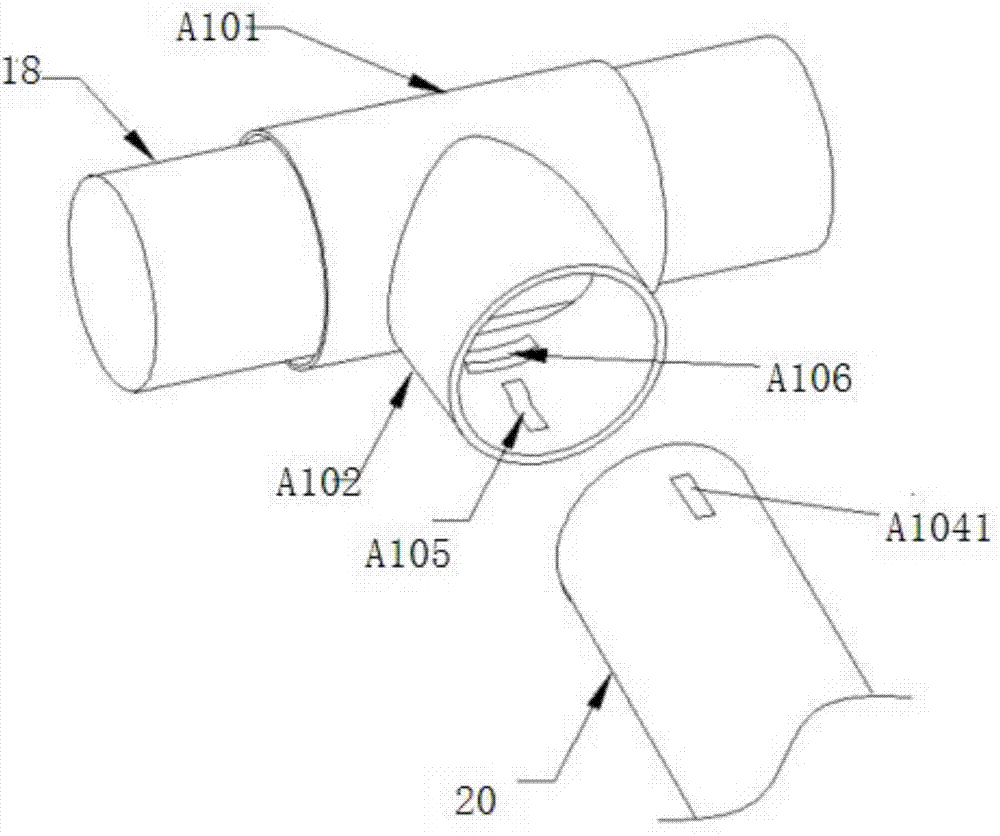

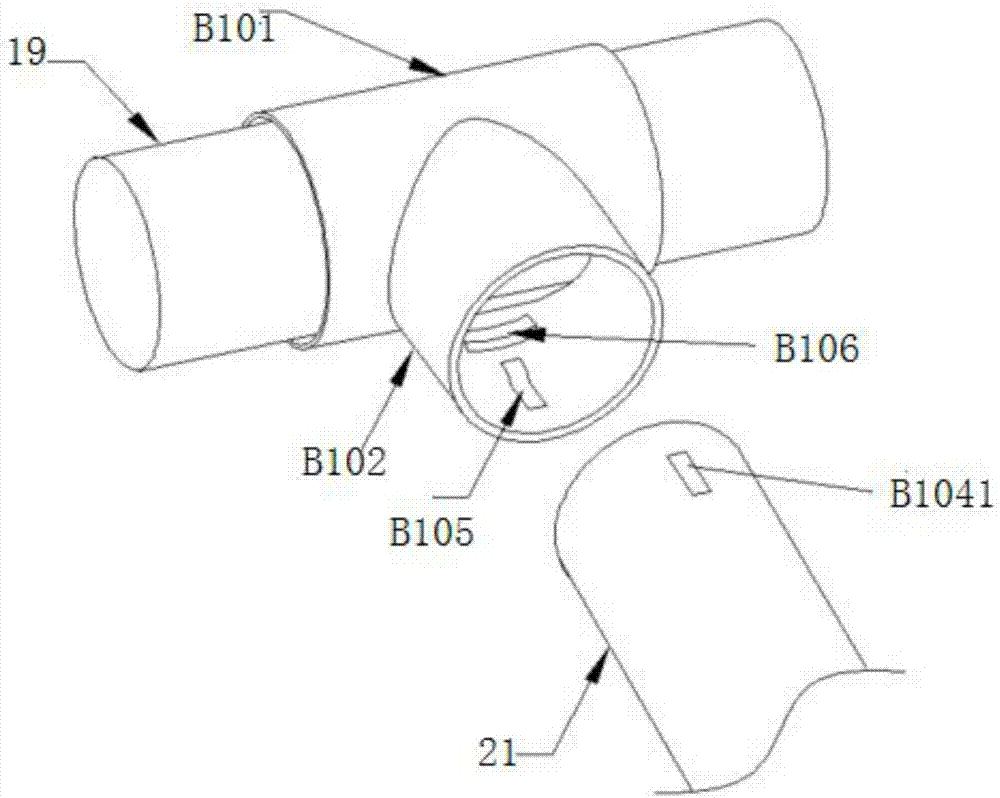

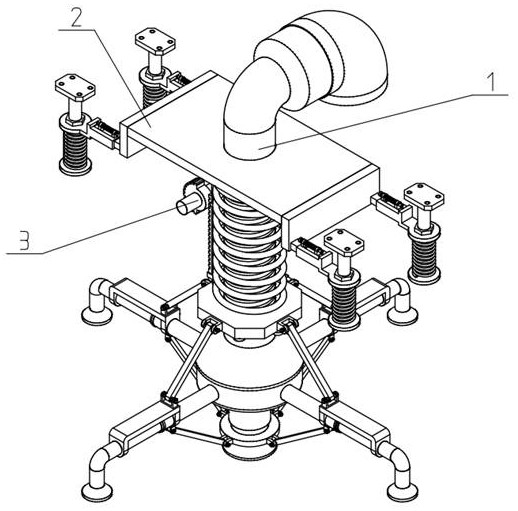

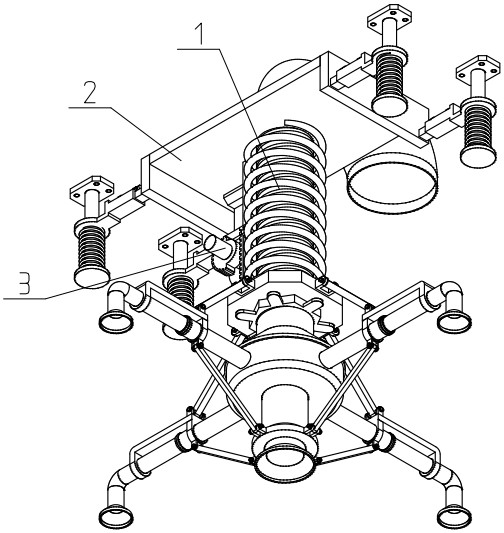

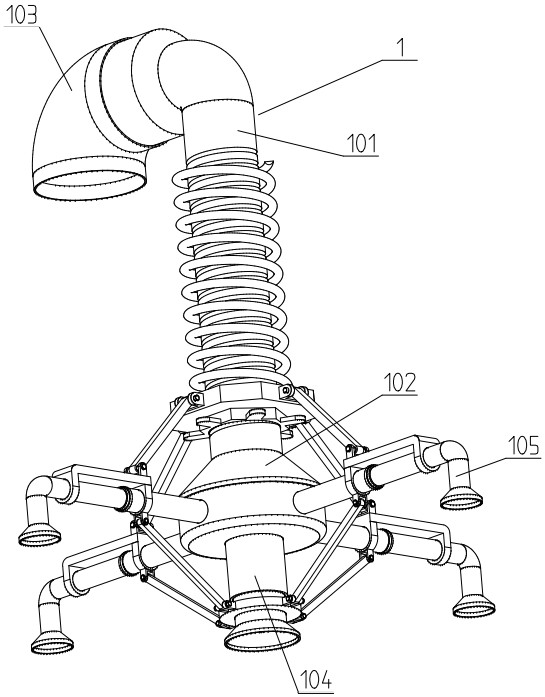

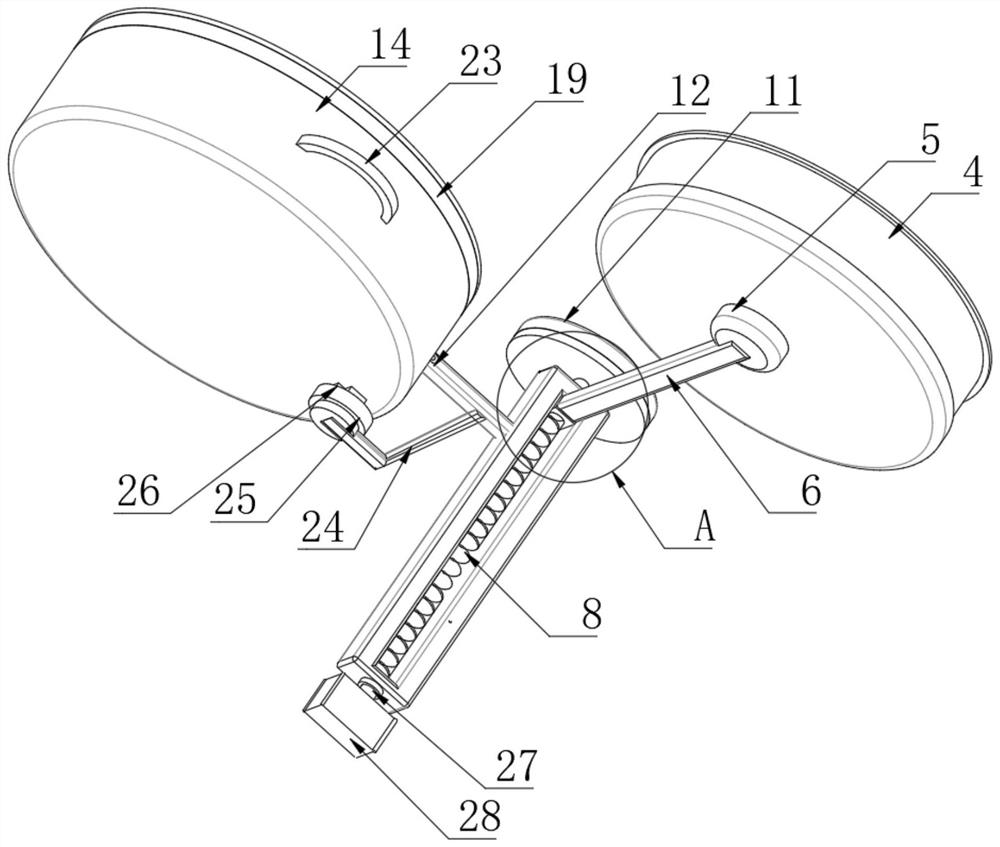

Grain plant ventilation system

ActiveCN113154585AReduce the impact of noiseGuaranteed working environmentDucting arrangementsMechanical apparatusAgricultural scienceAgricultural engineering

The invention relates to the field of modern agricultural ventilation systems, in particular to a grain plant ventilation system which comprises an exhaust fan, an exhaust pipeline and a damping mounting seat. The exhaust fan is connected into the exhaust pipeline in a matched mode so as to pump and exhaust air in a grain factory building to the outside of the grain factory building through the exhaust pipeline. The exhaust pipeline is fixed on the damping mounting seat, so that the exhaust pipeline is fixed in a grain plant through the damping mounting seat. The damping mounting seat comprises a center frame, a side frame, a vertical shaft, a damping spring, a spring seat and a connecting seat. The exhaust pipeline is fixed to the center of the center frame, and the side frames are fixed to the four corners of the center frame respectively. The four side frames are in sliding fit with the middle parts of the four vertical shafts. The damping mounting seat is arranged in the grain plant ventilation system, noise generated between the grain plant ventilation system and a grain plant in the working state can be effectively reduced, the damping effect can be achieved when the grain plant slightly vibrates, and the service life of the grain plant ventilation system can be guaranteed.

Owner:衡阳市稻香农业股份有限公司

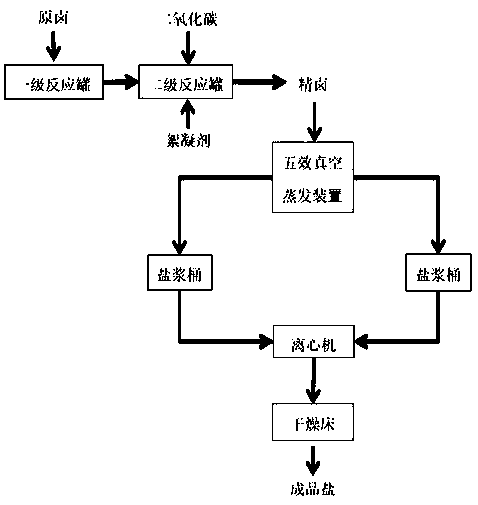

Method for removing peculiar smell in refined salt production

ActiveCN108862330AControl concentrationEfficient ConcentrationAlkali metal halide purificationEvaporationNational standard

The invention provides a method for removing peculiar smell in refined salt production. The method comprises the following steps: insoluble impurities in raw brine are removed, then the raw brine is purified, air is blown into in a purifying process, a part of micromolecular organic matters are removed by an aerating method, then a flocculant is added in the purifying process, micromolecular organic matter dissolved in water and fine granule matter suspending in the water are gathered to form macromolecular group precipitate, standing is performed, the precipitate is discharged out, multi-effect evaporation is performed on the purified refined brine, mother liquor is controlled by an unsaturated method in a multi-effect evaporation process, micromolecular organic matter is prevented from being attached to crystal salt, and edible salt meeting the national standard is obtained after evaporation and crystallization. All the used methods of the method disclosed by the invention are physical methods, and other matter is prevented from being added into; a production process has the advantages of safety, environmental friendliness, simpleness, visuality, small investment and low production cost; the produced finished-product edible salt has pure white appearance, whiteness of the edible salt is 85% or more, the edible salt has no foreign smell, and all items of indexes of the ediblesalt can meet and exceed the national standards.

Owner:中盐舞阳盐化有限公司

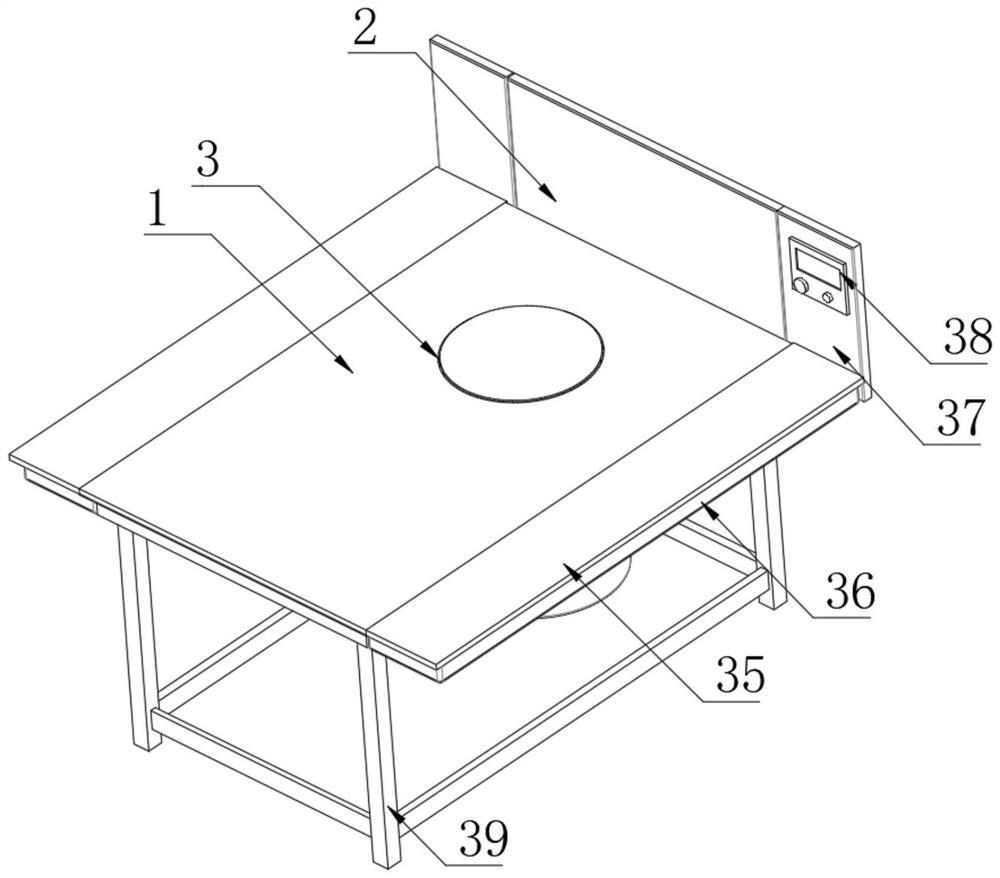

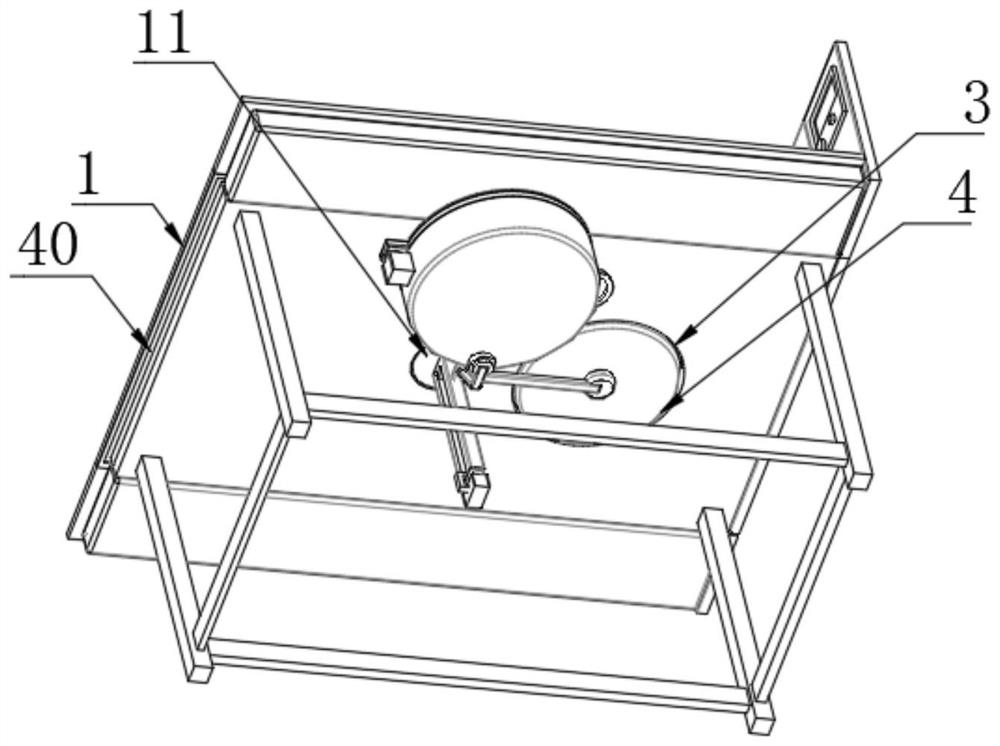

Nursing device special for obstetrics and gynecology department

The invention discloses a special nursing device for gynaecology and obstetrics, and belongs to the technical field of nursing devices, the special nursing device for gynaecology and obstetrics comprises tiled bedding, the top end of the tiled bedding is connected with a back backup plate, one side of the back backup plate is provided with a through hole, and a switching mechanism is arranged in the through hole; the switching mechanism comprises a supporting sleeve arranged in the through hole, and the bottom end of the supporting sleeve is connected with a supporting linkage block. The switching mechanism is adopted to enable the movable support to drive the supporting linkage block to move downwards, the positioning support drives the positioning clamping block to rotate, and the containing basin rotates to the position below the through hole, so that the through hole can be rapidly opened, a patient can directly relieve the hand on the flatly laid bedding and does not need to be supported by a person to enter a toilet for defecation, and the working efficiency is greatly improved. The patient can operate by himself / herself even if no person nurses, operation is simpler, the workload of medical staff is reduced, the patient is prevented from catching a cold, relieving operation is more convenient, and the nursing effect is better.

Owner:THE FIRST AFFILIATED HOSPITAL HENGYANG MEDICAL SCHOOL UNIV OF SOUTH CHINA

Dry-wet separation incineration device for household garbage disposal

InactiveCN113028416ATo achieve separate processingReduce moistureIncinerator apparatusWastewaterRefuse Disposals

The invention relates to the technical field of incineration devices, in particular to a dry-wet separation incineration device for household garbage disposal. The incineration device comprises an outer shell, wherein feeding ports are formed in the upper part of the outer shell, a first discharging port is formed in the lower part of the outer shell, a partition plate is arranged in the center of the outer shell and divides the interior of the outer shell into two spaces including a dry garbage channel, a wet garbage filtering area and a wet garbage drying area, a waste water collecting box is arranged below the wet garbage filtering area, and an incineration device body is fixedly installed below the first discharging port of the outer shell and comprises a heat insulation shell, igniters, a sliding shovel used for cleaning the interior of the incineration device body and a drawing door arranged at a second discharging port of the heat insulation shell. By means of the incineration device, the purpose of separating dry garbage from wet garbage and dewatering the wet garbage to make the wet garbage incinerated as soon as possible is achieved, and thus the technical problem that the working efficiency is affected as the time of waiting for incineration of wet garbage with high moisture is too long is solved.

Owner:杜增琴

Papaya juice and preparation method thereof

The invention relates to papaya juice and a preparation method thereof. In the preparation method, the peculiar smell of papaya is removed effectively, and the beneficial ingredients of the papaya are kept by a physical method and by adding natural raw materials appropriately. The scheme is that the preparation method comprises the following steps of: heating papaya normal juice to 63+ / -2 DEG C, maintaining for 60 minutes, cooling naturally to normal temperature, standing for over 24 hours, heating to 92+ / -2 DEG C, and maintaining at the constant temperature for 20 minutes; and cooling to normal temperature, and adding 0.5 percent of rose pollen, 1 percent of hawthorn normal juice and 4 percent of white sugar or honey.

Owner:高宝库

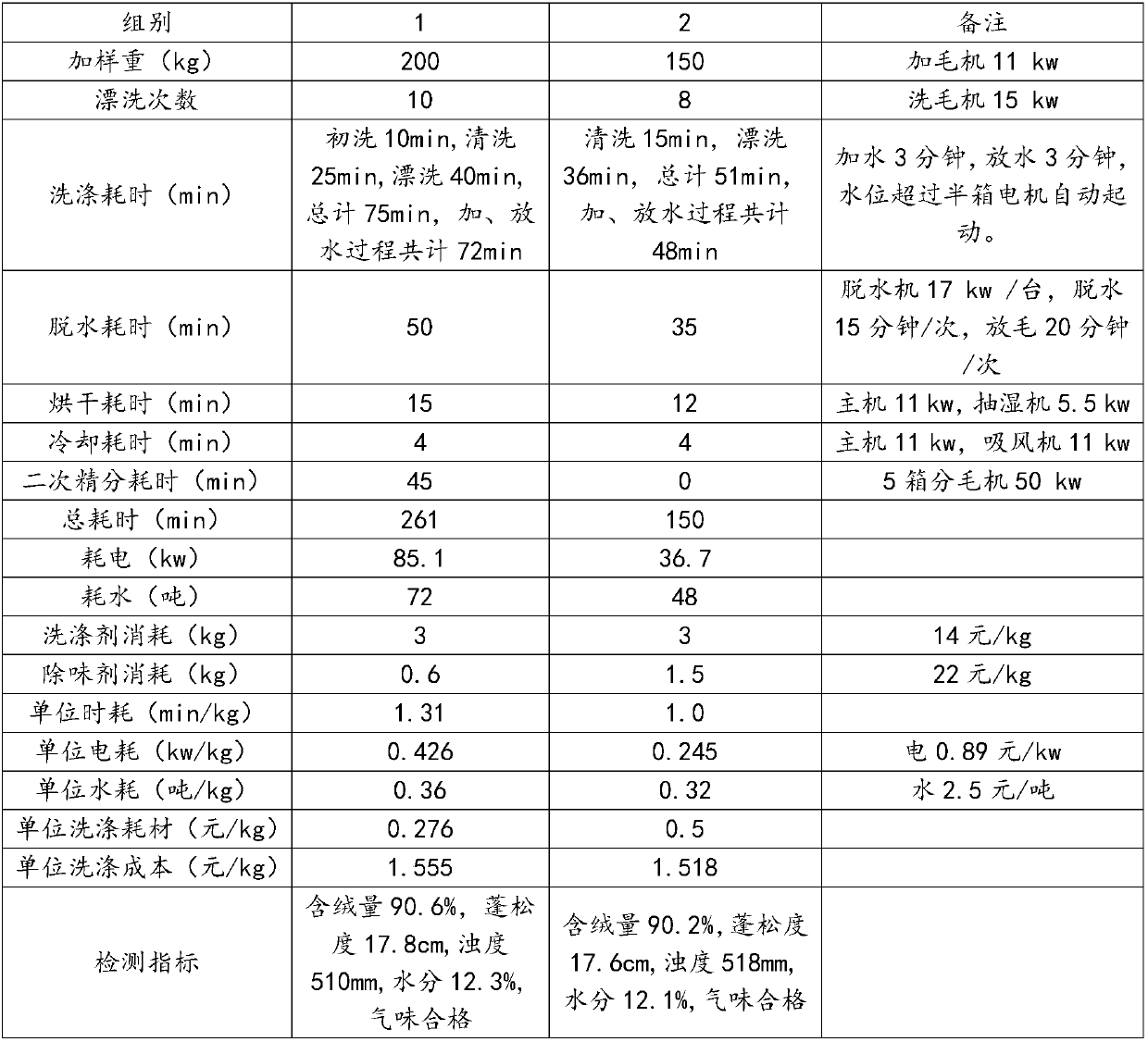

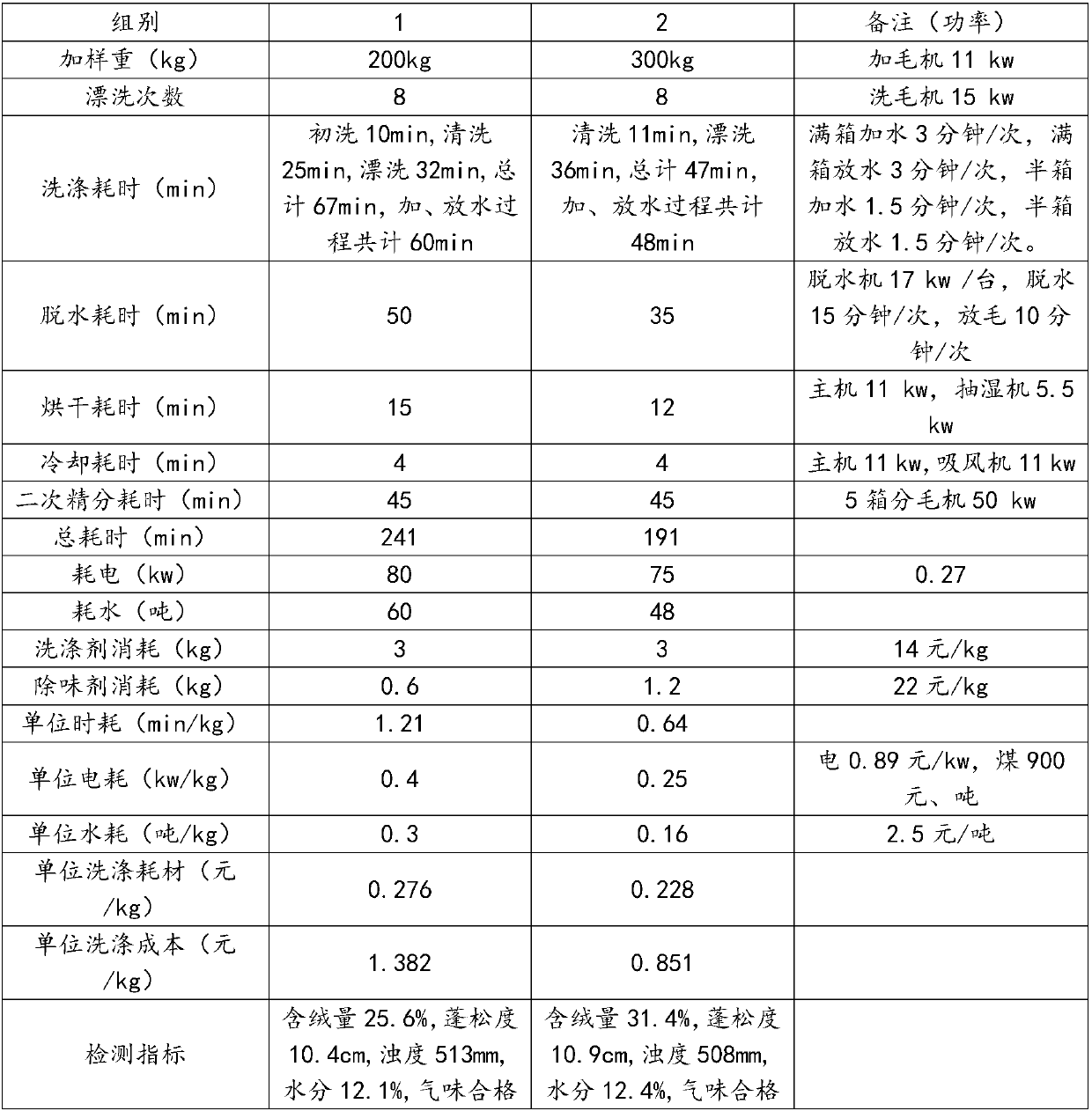

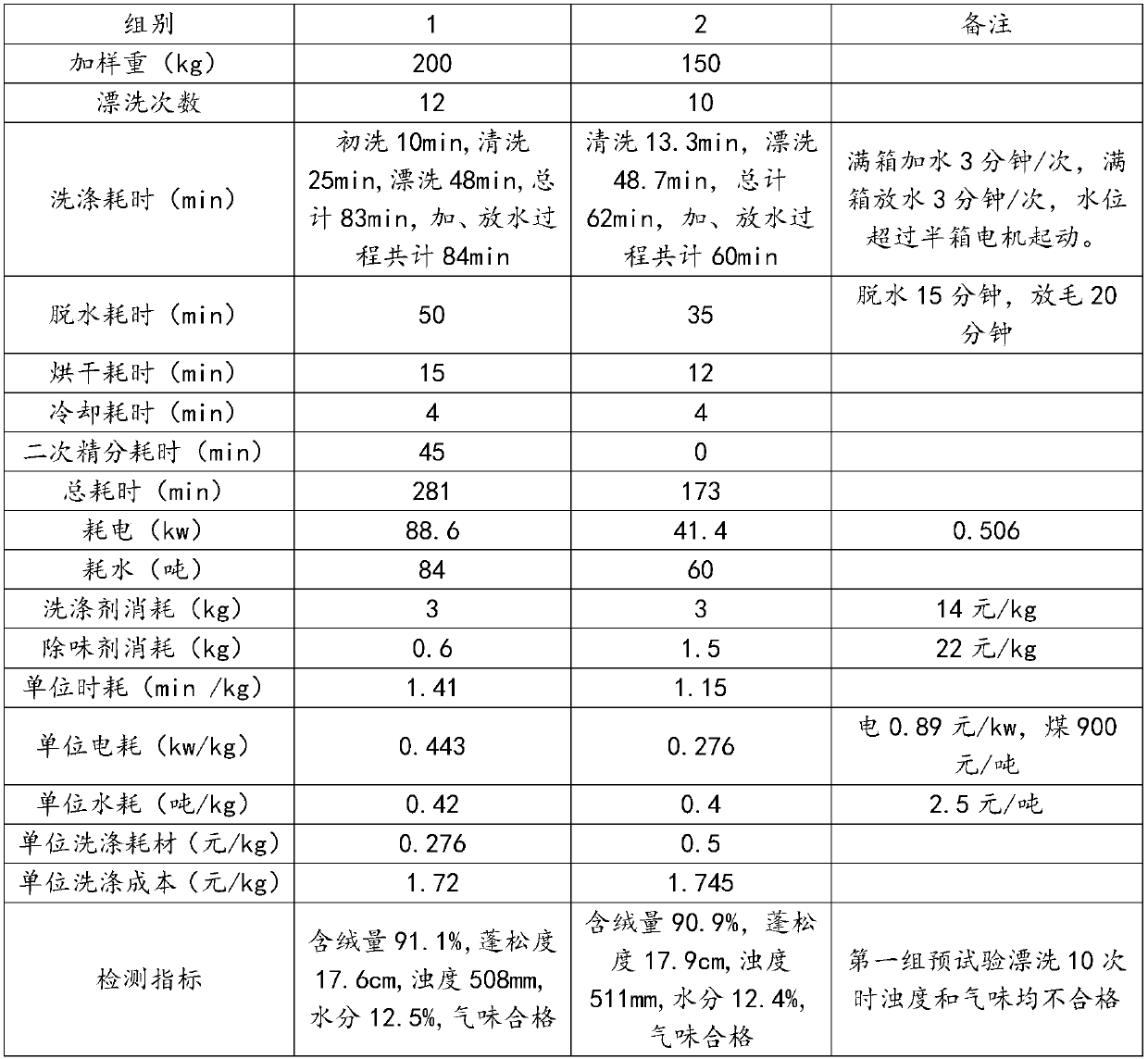

Down feather washing technology

InactiveCN107653494AReduce water consumptionImprove work efficiencyWool fibre washing/scouringElectricityEngineering

The invention discloses a down feather washing technology. The down feather washing technology includes the following steps: (1) rough separation; (2) refined separation; (3) washing; (4) dewatering;(5) drying; (6) cooling; (7) secondary refined separation; and (8) inspection. Original feathers are divided into feather hair and feather pieces, and the down content of the feather hair reaches above 75%. The washing process includes cleaning and rinsing; during cleaning, a semi-box of hot water is used; during rinsing, a full box of water at a normal temperature is used; when the feather hair and the feather pieces are rinsed for the last time, a semi-box of water is added; when the feather hair is rinsed for the last time, a deodorant is added; dewatering, drying, and cooling is performedon the washed feather hair and the washed feather pieces, the cooled feather hair is packaged, and secondary refined separation is performed on the cooled feather pieces; the feather hair and the feather pieces are packaged respectively; and the packaged feather hair is inspected. The washing technology can reduce the frequency of rough cleaning and rinsing, can improve the efficiency, can reduceenergy consumption, and can save water, electricity, and the cost; and the feather hair can meet the national standard demand.

Owner:JIANGSU INST OF POULTRY SCI

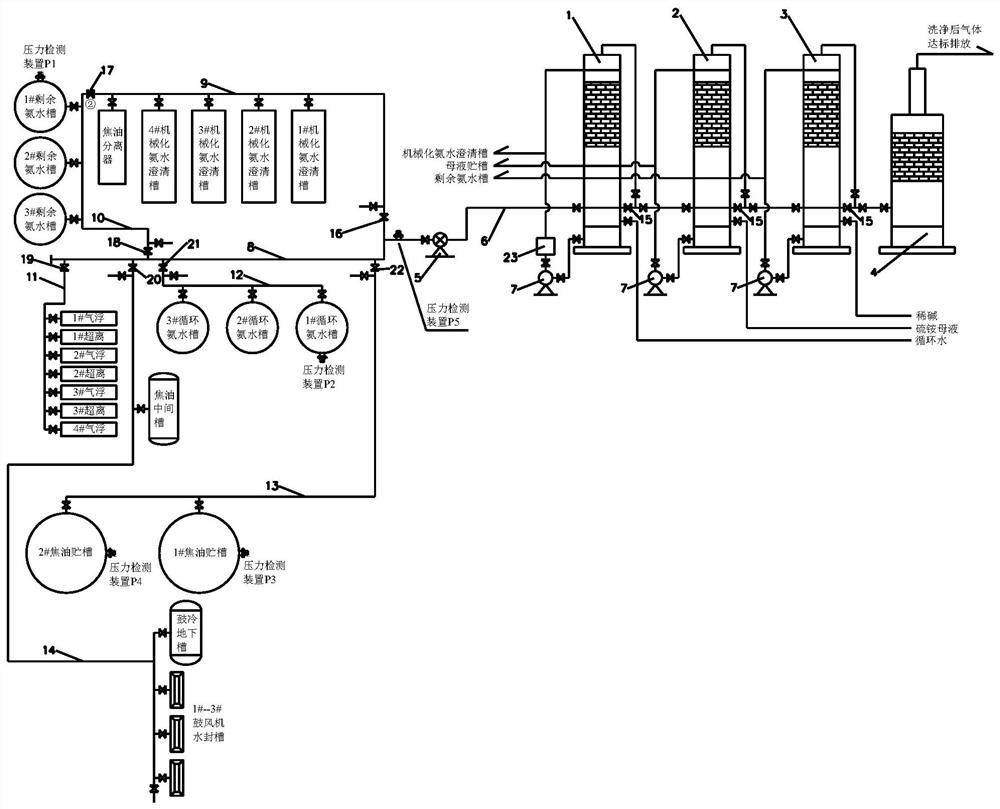

Washing system and method for tail gas of blower cooling tank area

InactiveCN112275116ARealize washing and purificationSatisfy the process requirements of cycle operationDispersed particle separationAcid washingEngineering

The invention relates to the technical field of coking tail gas treatment, in particular to a washing system and method for tail gas of a blower cooling tank area. The system comprises a water washingtower, an acid washing tower, an alkaline washing tower, an activated carbon adsorption tower, a fan and a tail gas pipeline, wherein the water washing tower, the acid washing tower, the alkaline washing tower and the activated carbon adsorption tower are connected in series through pipelines and then connected with the tail gas pipeline through a first connecting pipe, and the fan is mounted onthe first connecting pipe; and the tail gas pipeline comprises a main tail gas pipe and first to sixth branch tail gas pipes, the first branch tail gas pipe is connected with a mechanical ammonia water clarification tank and a tar separator, the second branch tail gas pipe is connected with a residual ammonia water tank, the third branch tail gas pipe is connected with a tar intermediate tank, a super centrifuge and an air floatation tar remover, the fourth branch tail gas pipe is connected with a circulating ammonia water tank, the fifth branch tail gas pipe is connected with a tar storage tank, and the sixth branch tail gas pipe is connected with a blower cooling underground tank and a blower water seal tank. According to the invention, the process requirements of a drum condensation tank area are met, and the purpose of zero emission of tail gas in the tank area of a blower cooling procedure is achieved.

Owner:鞍钢化学科技有限公司

A kind of preparation method of photocatalytic self-cleaning nanofiber mat

InactiveCN103966769BWith clean airEfficient decompositionFilament/thread formingNon-woven fabricsFiberCompression molding

The invention discloses a method for preparing photocatalysis self-cleaning nanometer fiber felt. The method includes the steps that nanometer titania powder, nanometer diatom ooze powder and granules are evenly mixed and then placed in an extruder, and a mixture is extruded out at a working temperature ranging from 80 DEG C to 240 DEG C of the extruder and is cut into photocatalysis self-cleaning master batches; the photocatalysis self-cleaning master batches are added into the granules, the photocatalysis self-cleaning master batches and the granules are evenly mixed and then dissolved in an organic solvent, a mixture is stirred at an indoor temperature until complete dissolving is achieved, and then a spinning solution is prepared, wherein the concentration of solid matter ranges from 50g / L to 100g / L; electrostatic spinning is conducted through the spinning solution, and then a photocatalysis self-cleaning nanometer fiber layer is acquired; the photocatalysis self-cleaning nanometer fiber felt is acquired through compression molding. The fiber felt prepared through the method has the high specific area, can absorb and effectively decompose organic matter, decompose the peculiar smell produced in daily life, adjust the environment humidity, and can be used as a carpet, textile and garment materials, medical materials and the like.

Owner:NANTONG UNIVERSITY

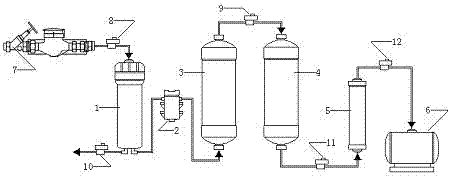

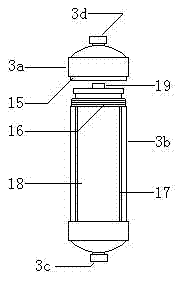

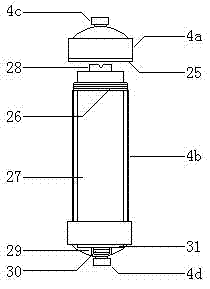

Manufacturing method of pre-proposed filtering and pressure type backwashing water purifier

InactiveCN103922496AEffective emission controlEffective odorMultistage water/sewage treatmentReverse osmosisFilter element

The invention relates to a manufacturing method of a pre-proposed filtering and pressure type backwashing water purifier. The water purifier comprises a pressure type backwashing and discharging unit, a pressurizing pump, a pressure tank, a compressed active carbon filter element, a post-proposed active carbon filter element and a microfiltration membrane filter device. The water purifier is characterized by further comprising a reverse osmosis (RO) membrane filter device, wherein a spiral inner thread joint connected with a barrel is arranged on an upper seal cover of a closed container, a spiral outer thread joint connected with the upper seal cover is formed at the upper opening of the barrel, a circular gripper tube is arranged at the bottom of the closed container and can effectively fix the membrane shell of the RO membrane, an RO membrane filter element is arranged in the middle of the membrane shell, an insertion nozzle is arranged at the middle part of the upper end of the membrane shell, a seal ring is arranged at the lower end of the membrane shell, a concentrated water channel is arranged around the membrane shell, a water inlet is formed at the top of the closed container and a water outlet is formed at the bottom of the closed container. The water outlet of the microfiltration membrane filter device is communicated with the water inlet of the RO membrane filter device. The pre-proposed filtering and pressure type backwashing water purifier is economic and practical.

Owner:四川金堂海纳生物医药技术研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com