Three-stage filtering water tap

A three-stage filtration and faucet technology, applied in the direction of filtration and separation, valve details, valve housing structure, etc., can solve problems such as increased production costs, low yield, and impact on drinking health, so as to remove impurities and odors and improve service life , the effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

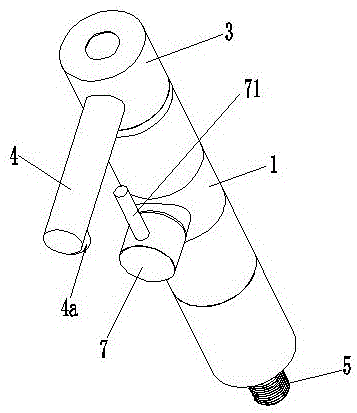

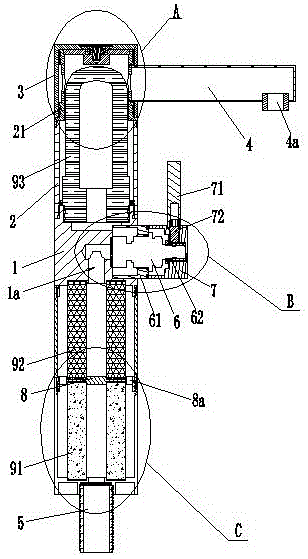

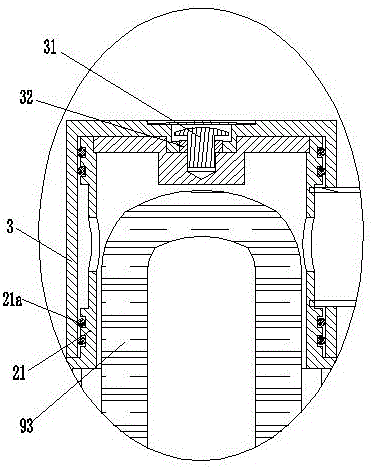

[0028] Embodiment one, such as Figure 1 to Figure 6 as shown,

[0029] A three-stage filter faucet, including a faucet body 1, a sleeve 2 is connected to the upper part of the faucet body 1, and a connecting piece 21 is arranged on the upper end of the sleeve 2, and the connecting piece 21 is provided with a sleeve capable of 360° with the connecting piece 21. Rotate the cover 3 that fits, the cover 3 is connected with a water outlet pipe 4, and the water outlet pipe 4 is provided with a water outlet 4a; the lower part of the faucet main body 1 is provided with a water inlet 1a, and the lower part of the faucet is connected with a water inlet pipe 5. The water inlet pipe 5 is connected with the water inlet hole 1a, and the water inlet hole 1a of the faucet body 1 is connected with the water outlet pipe 4 through the valve core 6. A spool sleeve 62 is provided, and a hand wheel 7 is arranged outside the spool sleeve 62; a primary filter element 91, a secondary filter element ...

Embodiment 2

[0047] Embodiment two, such as Figure 7 with Figure 8 as shown,

[0048] The structure of the faucet in this embodiment is similar to the structure of the faucet in Embodiment 1, the difference is that in this embodiment,

[0049] The first-stage filter element 91 is a ceramic filter element, the second-stage filter element 92 is an activated carbon filter element, and the third-stage filter element 93 is a PPF cotton filter element; the first-stage filter element 91 is arranged under the main body 1 of the faucet, and the second-stage filter element 92 and the third-stage filter element 93 are arranged on the Above the main body 1 of the faucet.

[0050] In the embodiment, the activated carbon filter element has a cylindrical structure, and the PPF cotton filter element has a ring structure.

[0051] working principle:

[0052] When turning the hand wheel 7 to turn on the faucet, water enters the faucet from the water inlet pipe 5. During the water inflow process, the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com