an aluminum alloy

A technology of aluminum alloy and aluminum liquid, applied in the field of aluminum alloy, can solve the problems of high rigidity, low density, high strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

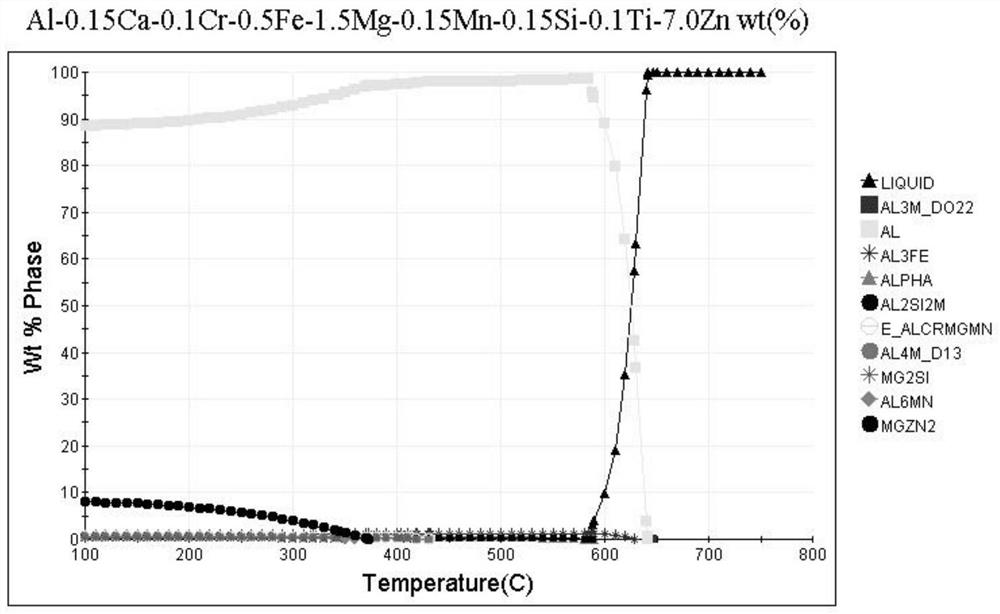

[0038] 0.5wt% Fe, 1.5wt% Mg, 7wt% Zn, 0.1wt% Cr, 0.15wt% Ca, 0.1wt% Ti, 0.2wt% Ce, 0.15wt% Y, 0.15wt% Si, 0.15wt% Mn;

[0039] Such as figure 1 As shown, Zn is very easy to dissolve in molten aluminum, and dissolves quickly. Within the range of internal oxidation temperature, the dissolution reaction of Zn is very thorough, which ensures that MgZn2 in solid solution state can be fully demelted, and greatly improves Increase the strength of aluminum alloy and improve its impact resistance.

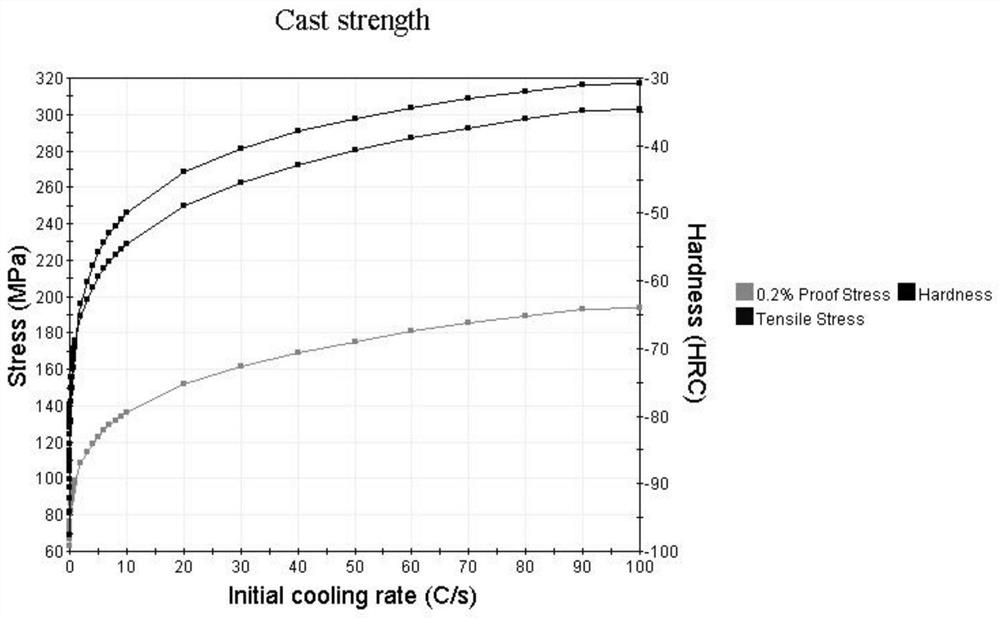

[0040] Such as figure 2 As shown, due to the addition of Zn, the tensile strength (Tensile stress) and hardness (Hardness) of the aluminum alloy are simultaneously increased, and have higher impact resistance.

Embodiment 2

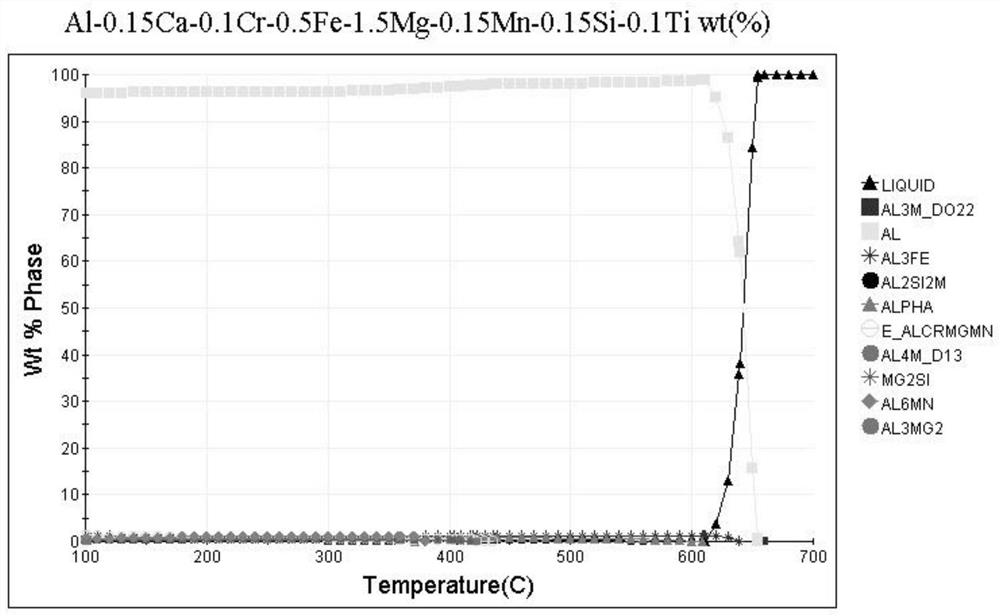

[0042] 0.5wt% Fe, 1.5wt% Mg, 10wt% Zn, 0.1wt% Cr, 0.15wt% Ca, 0.1wt% Ti, 0.2wt% Ce, 0.15wt% Y, 0.15wt% Si, 0.15wt% Mn;

[0043] Such as image 3 As shown, when the rest of the ingredients remain unchanged and only the content of Zn is increased, Zn dissolves easily and quickly in molten aluminum. When the internal oxidation temperature range is not reached, the dissolution reaction of Zn is very thorough, destroying the entire smelting process. The smelting balance of the alloyed metal content will lead to a decrease in the hardness of the aluminum alloy, making it impossible to use doors and windows.

[0044] Such as Figure 4 As shown, when the rest of the ingredients remain unchanged and only the content of Zn is increased, although the tensile strength (Tensilestress) is improved, the hardness of the aluminum alloy (Hardness) is reduced, which may easily lead to breakage of the aluminum alloy, which is not suitable for normal use.

[0045] Based on the comparison betwee...

Embodiment approach

[0048] As an embodiment of the present invention, the preparation method of the aluminum alloy includes the following steps:

[0049] S1. Ingredients: Calculate the amount of aluminum alloy raw materials and prepare the aluminum alloy raw materials according to the ratio. Put the prepared aluminum alloy raw materials into the ultrasonic vibration equipment with a filter on the bottom layer, and perform ultrasonic vibration for 20-30 minutes, while oscillating High-pressure anhydrous ethanol impacts aluminum alloy raw materials, and finally obtains aluminum alloy raw materials with a pure surface; by using high-pressure anhydrous ethanol to impact aluminum alloy raw materials while oscillating, unnecessary impurities attached to the surface of aluminum alloy raw materials can be cleaned, reducing the melting process. The content of impurities in the medium improves the performance of aluminum alloy, and the use of absolute ethanol can quickly volatilize in the subsequent smeltin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com