Manufacture method of integrated countertop type water purifier

The technology of a water purifier and a cylinder body is applied in the field of water purification equipment to achieve the effect of high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

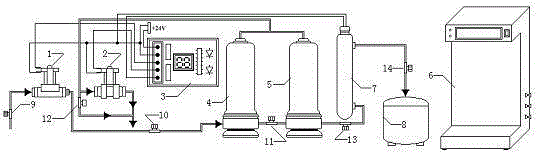

[0015] figure 1 It shows the situation that the water treatment device of the present invention is equipped with a manual integrated reverse flushing graded sewage control system device. For example, for urban and rural households, tap water or self-made tap water is directly introduced, and through the valve 9 and the normally open solenoid valve 1 And valve 10 is sent in the device of the present invention to carry out filtering treatment, and the water after processing is sent in the pure water tank 8 through valve 14 for use.

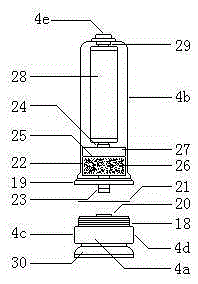

[0016] figure 2 Among them, the high-precision PP fiber cotton filter device 4 is an airtight container composed of a cylinder body 4b and a lower valve seat 4a, the cylinder body 4b and the lower valve seat 4a are connected in a screw, and the bottom of the airtight container lower valve seat is provided with a fixed pedestal 30. The upper part of the lower valve seat is provided with a spiral outer thread port 18 connected to the cylinder body, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com