Method for preparing photocatalysis self-cleaning nanometer fiber felt

A nanofiber, self-cleaning technology, applied in fiber processing, textiles and papermaking, non-woven fabrics, etc., can solve problems such as pollution, poor living conditions, and pollute the ecological environment, and achieve the effect of simple production process and decomposition of harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

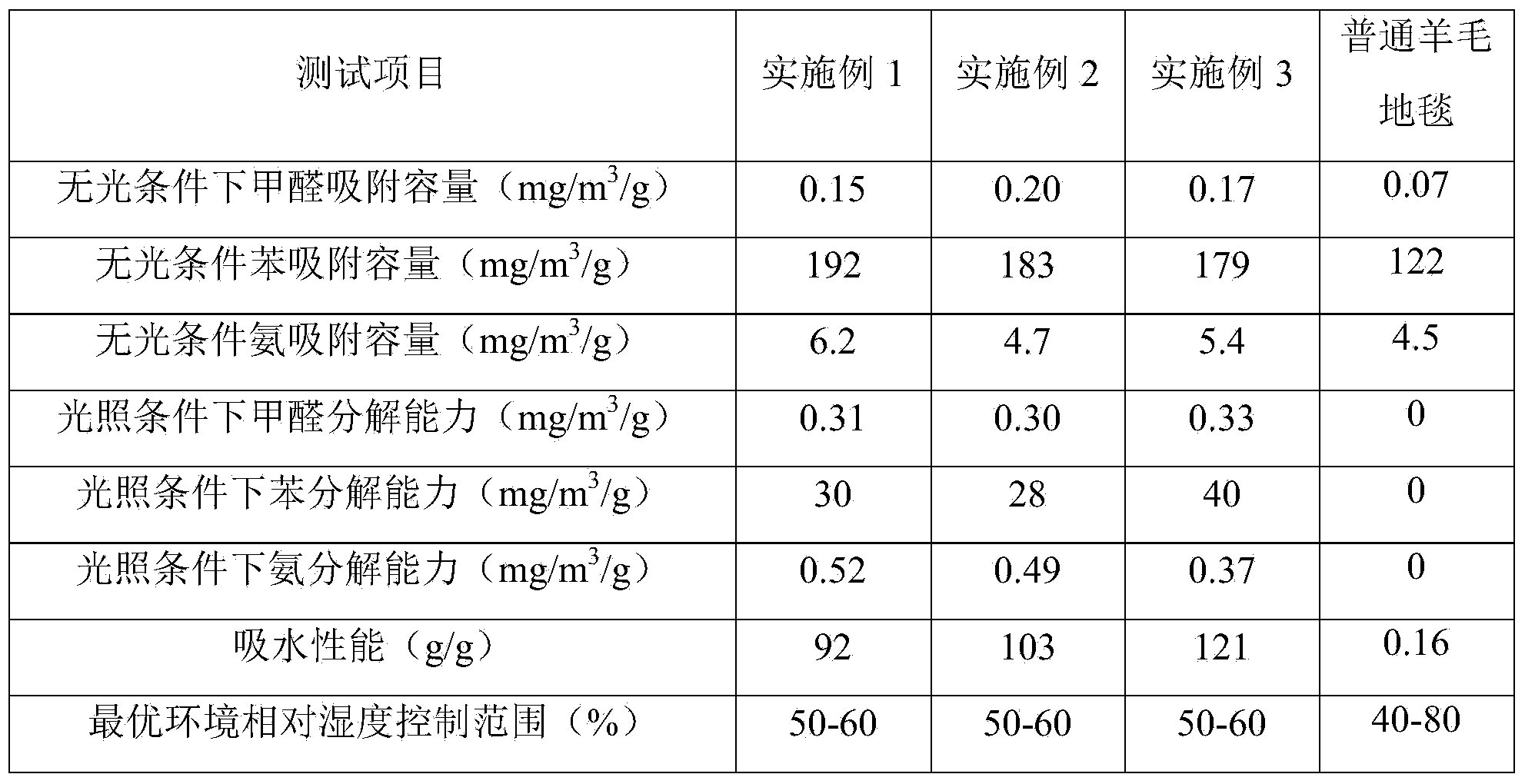

Examples

Embodiment 1

[0026] A preparation method of photocatalytic self-cleaning nanofiber felt, comprising the steps of:

[0027] (1) Preparation of photocatalytic self-cleaning masterbatch

[0028] Commercially available nano-titanium dioxide powder (quality standard particle diameter 5-10nm) 150g, nano diatom mud powder 100g (wherein, active carbon white powder (quality standard particle diameter is 50-100nm, BET surface area is 5-300m 2 / g) 43.75g, diatom mud (quality standard particle size is 50-100nm, BET surface area is 5-300m 2 / g) 43.75g, YPO4: Ce, Th (mass standard particle size is 50-100nm, BET surface area is 5-300m 2 / g) 12.5g) and 750g of polyamide pellets, put into the extruder after mixing, extrude and pelletize at the working temperature of the extruder at 180°C to obtain photocatalytic self-cleaning masterbatch;

[0029] (2) Preparation of spinning solution

[0030] Add 1000g of photocatalytic self-cleaning masterbatches prepared in step (1) to 19000g of polyamide pellets, dis...

Embodiment 2

[0033] A preparation method of photocatalytic self-cleaning nanofiber felt, comprising the steps of:

[0034] (1) Preparation of photocatalytic self-cleaning masterbatch

[0035] Commercially available nano titanium dioxide powder (quality standard particle diameter 5-10nm) 40g, nano diatom mud powder 40g (wherein, active carbon white powder (quality standard particle diameter is 50-100nm, BET surface area is 5-300m 2 / g) 20g, diatom mud (quality standard particle size is 50-100nm, BET surface area is 5-300m 2 / g) 18g, MgSrBF3:Eu (mass standard particle size is 50-100nm, BET surface area is 5-300m 2 / g) 2g) and polylactic acid pellets 20g, put into the extruder after mixing, extrude and cut into pellets at the working temperature of the extruder to obtain photocatalytic self-cleaning masterbatch;

[0036] (2) Preparation of spinning solution

[0037] Add 100 g of photocatalytic self-cleaning masterbatches prepared in step (1) to 900 g of polylactic acid pellets, dissolve in...

Embodiment 3

[0041] A preparation method of photocatalytic self-cleaning nanofiber felt, comprising the steps of:

[0042] (1) Preparation of photocatalytic self-cleaning masterbatch

[0043] Commercially available nano-titanium dioxide powder (quality standard particle diameter 5-10nm) 30g, nano diatom mud powder 29.9g (activated carbon white powder (quality standard particle diameter is 50-100nm, BET surface area is 5-300m 2 / g) 13.3g, diatom mud (quality standard particle size is 50-100nm, BET surface area is 5-300m 2 / g) 13.3g, MgSrBF3:Eu (mass standard particle size is 50-100nm, BET surface area is 5-300m 2 / g) 3.3g) and 40g of polyacrylonitrile pellets, put into the extruder after mixing, extrude and pelletize at the working temperature of the extruder at 200°C to obtain photocatalytic self-cleaning masterbatch;

[0044] (2) Preparation of spinning solution

[0045] Add 99.9 g of photocatalytic self-cleaning masterbatches prepared in step (1) to 1235 g of polyacrylonitrile pellets...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com