Down feather washing technology

A technology of down washing process, which is applied in the field of energy-saving and water-saving down washing process, can solve the problems of low efficiency in the initial washing step, long drying process time, and low efficiency in the dehydration process, and achieve seamless connection, efficiency improvement, and reduction The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1350

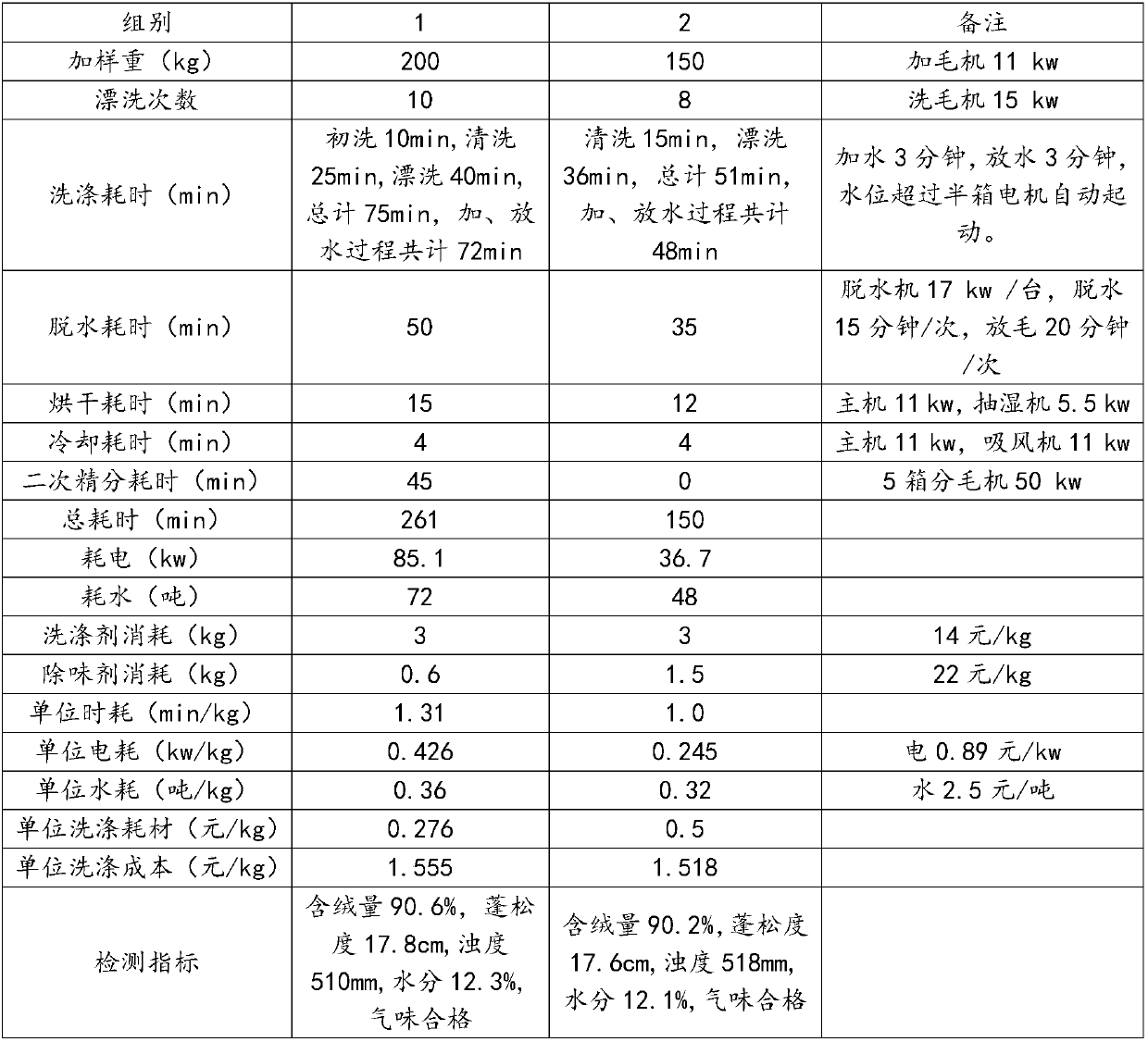

[0042] Embodiment 1 350kg better quality goose down washing comparison test

[0043] Select 350kg of goose down from the 5th box wool with better quality in the same batch, and divide it into two groups for testing. The first group takes 200kg and operates according to the original washing process, and the second group takes 150kg according to the optimized washing process provided by the present invention. operate.

[0044] The process used for the first group of goose down washing is: after feeding 200Kg, add 6 tons of normal temperature water for initial washing for about 10 minutes, then release the water, add 6 tons of 45°C-50°C hot water, add 3kg of detergent, wash for 25 minutes, release the water, and rinse 10 times , adding 6 tons of normal temperature water each time, rinsing for 4 minutes each time, adding 0.6kg deodorant for the last rinsing, stirring for 5 minutes to release the fluff pulp, then dehydrating, dehydrating twice, and dehydrating takes 30 minutes in t...

Embodiment 2

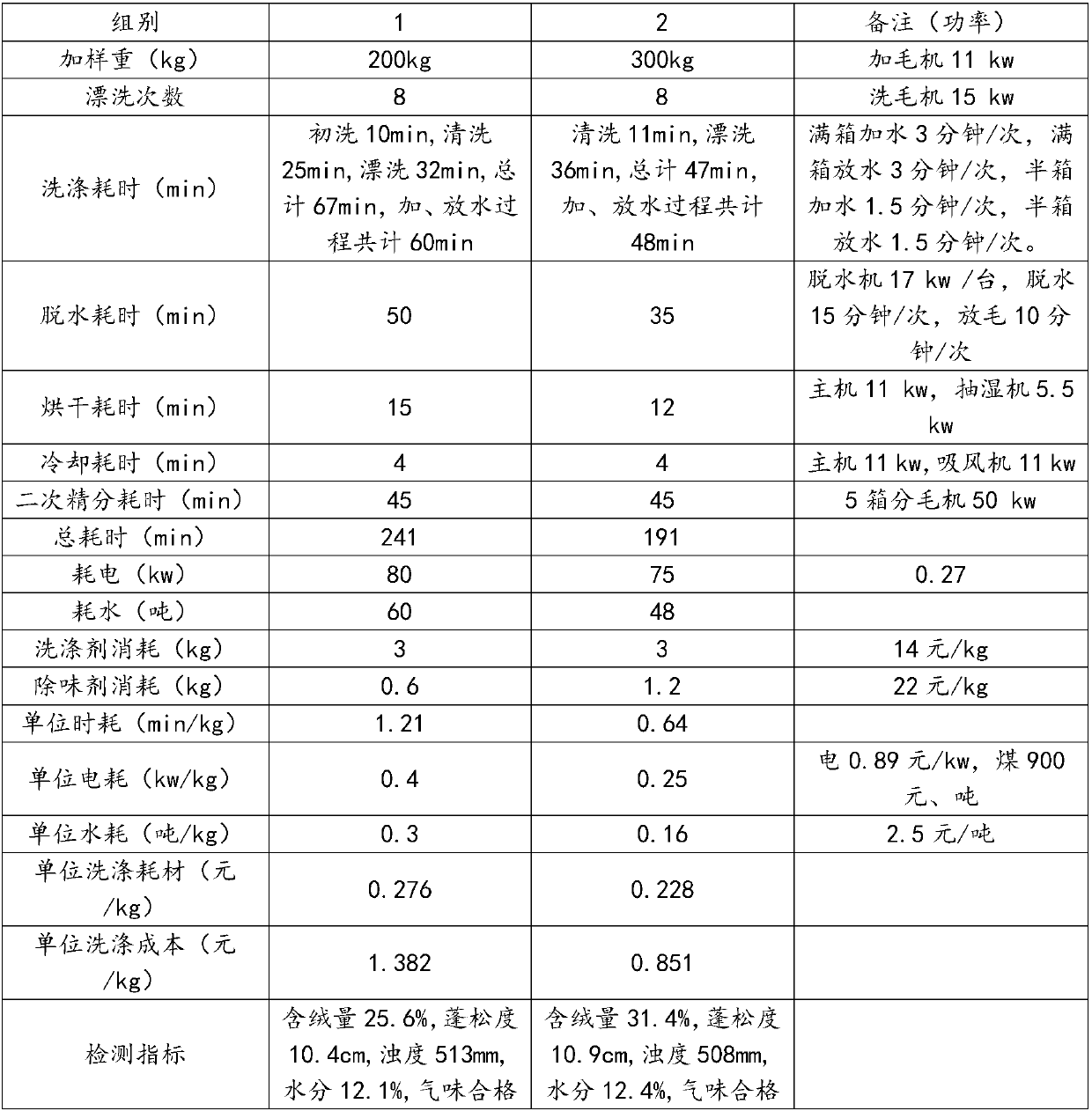

[0051] Embodiment 2 500kg of better quality goose feather flakes washing comparison test

[0052] Choose 500kg in the better goose feather chip raw material (the 2nd-4 box wool) of same batch quality, divide into two groups and carry out the test, the first group gets 200kg and operates according to the original washing process, and the second group gets 300kg and provides according to the present invention The optimized washing process operation.

[0053] The washing process of the first group of goose feather flakes is the same as the washing process of the first group of goose down in Example 1, except that it is rinsed 8 times, which will not be repeated here.

[0054] The technology of the second group of goose feather flakes washing is: feed intake 300kg, add 3 tons of hot water of 58 ℃ and clean 660s (being 11min), detergent adds 3kg (1% of pinna weight), deodorant adds 1.2kg (pinna weight) 0.4% of the weight), rinse 8 times, add 6 tons of normal temperature water to e...

Embodiment 3

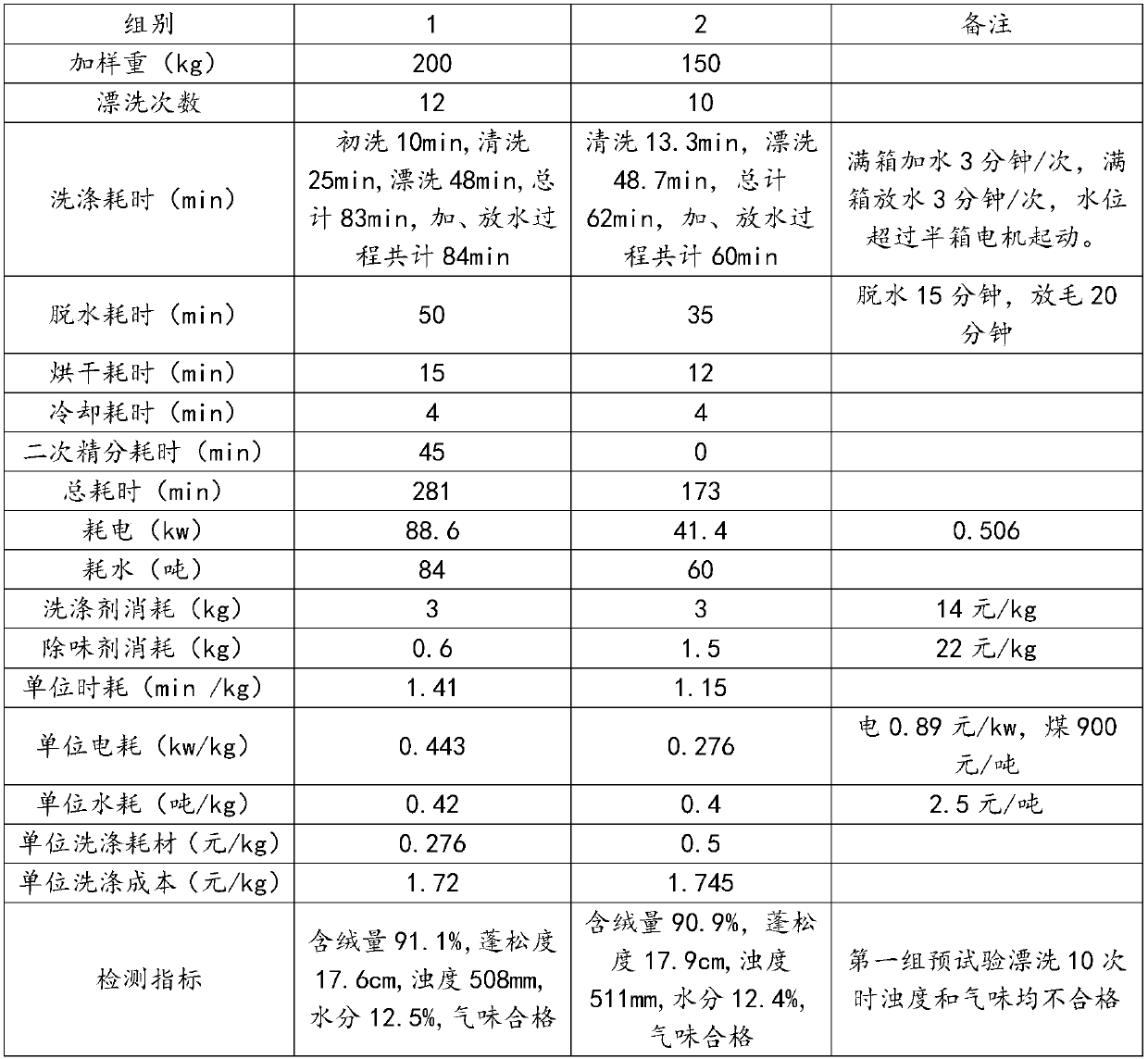

[0060] Embodiment 3 350kg duck down washing comparison test with poor quality

[0061] Choose 350kg in the duck down raw material (the 5th box wool) with poor quality of the same batch, divide into two groups and carry out the test, the first group gets 200kg and operates according to the original washing process, and the second group gets 150kg after the optimization provided by the present invention washing process operation.

[0062] The washing process of the first group of duck down is the same as the washing process of the first group of goose down in Example 1, except for 12 times of rinsing, which will not be repeated here.

[0063] The process of the second group of duck down washing is: feed 150kg, add 4 tons of hot water at 60°C for 800s (i.e. 13.3min), add 3kg of detergent (2% of the weight of the down), and add 1.2kg of deodorant (2% of the weight of the down) 0.8%), rinse 10 times, add 6 tons of normal temperature water for each of the first 9 rinses, rinse for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com