Method for removing peculiar smell in refined salt production

A technology for refining salt and odor, applied in the field of salt chemical industry, can solve the problems of high input cost, high operating cost, and non-compliance with food production requirements, and achieve the effect of low production cost, less investment and safe production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The method for removing peculiar smell in the production of refined salt in this embodiment includes the following steps: the original brine is purified after removing insoluble impurities, blowing gas into the purification process to remove some small molecular organic matter through aeration method, and using a carbon dioxide compressor to extract the purified brine The boiler flue gas is passed into the secondary reaction tank, and the pH value is detected with a pH meter after ventilating. When the pH value is less than 7, stop feeding carbon dioxide; then add a flocculant during the purification process to dissolve the small Molecular organic matter and fine-grained substances suspended in water aggregate into macromolecular clusters to precipitate, let stand, and discharge the precipitate. The purified refined brine undergoes multi-effect evaporation. Attached to the crystalline salt, after evaporation and crystallization, the edible salt meeting the national stand...

Embodiment 2

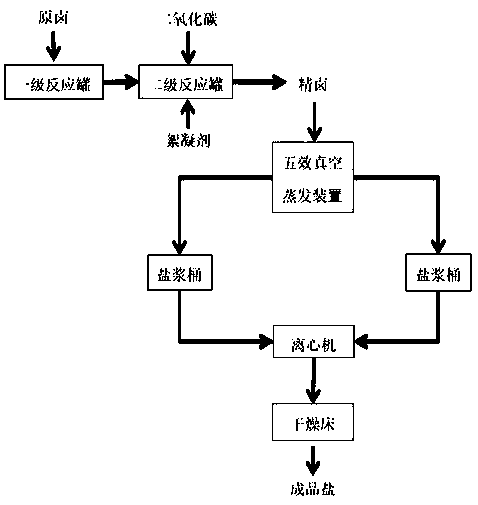

[0020] This embodiment removes the technological process of peculiar smell in refined salt production as figure 1 As shown, the raw halogen goes through the primary reaction tank to remove insoluble impurities and then enters the secondary reaction tank for purification. Carbon dioxide gas is blown into the secondary reaction tank to remove some small molecular organics through aeration method, and the purified halogen is extracted by a carbon dioxide compressor. After the boiler flue gas, the boiler flue gas is passed into the secondary reaction tank, and the pH value is detected with a pH meter after ventilation. When the pH value is less than 7, stop feeding carbon dioxide; then add a flocculant to the secondary reaction tank to make the water Dissolved small molecular organic matter and suspended fine particles in water aggregate into macromolecular clusters for precipitation, stand still, and the sediment is pumped together with the mud to the Doyle settler through the mud...

Embodiment 3

[0024] The method for removing peculiar smell in the production of refined salt in this embodiment includes the following steps: the raw brine passes through the primary reaction tank to remove insoluble impurities and then enters the secondary reaction tank for purification, and blows carbon dioxide gas into the secondary reaction tank through the aeration method Remove some small molecular organic matter, use a carbon dioxide compressor to extract the purified boiler flue gas, pass the boiler flue gas into the secondary reaction tank, and use a pH meter to detect the pH value after ventilation, and stop feeding carbon dioxide when the pH value is less than 7 ; Then add flocculant in the secondary reaction tank to make the small molecule organic matter dissolved in the water and the fine particle substance suspended in the water gather into a macromolecular mass for precipitation, let it stand for 2 hours, and the sediment will be pumped to the Doyle settler through the mud pum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com