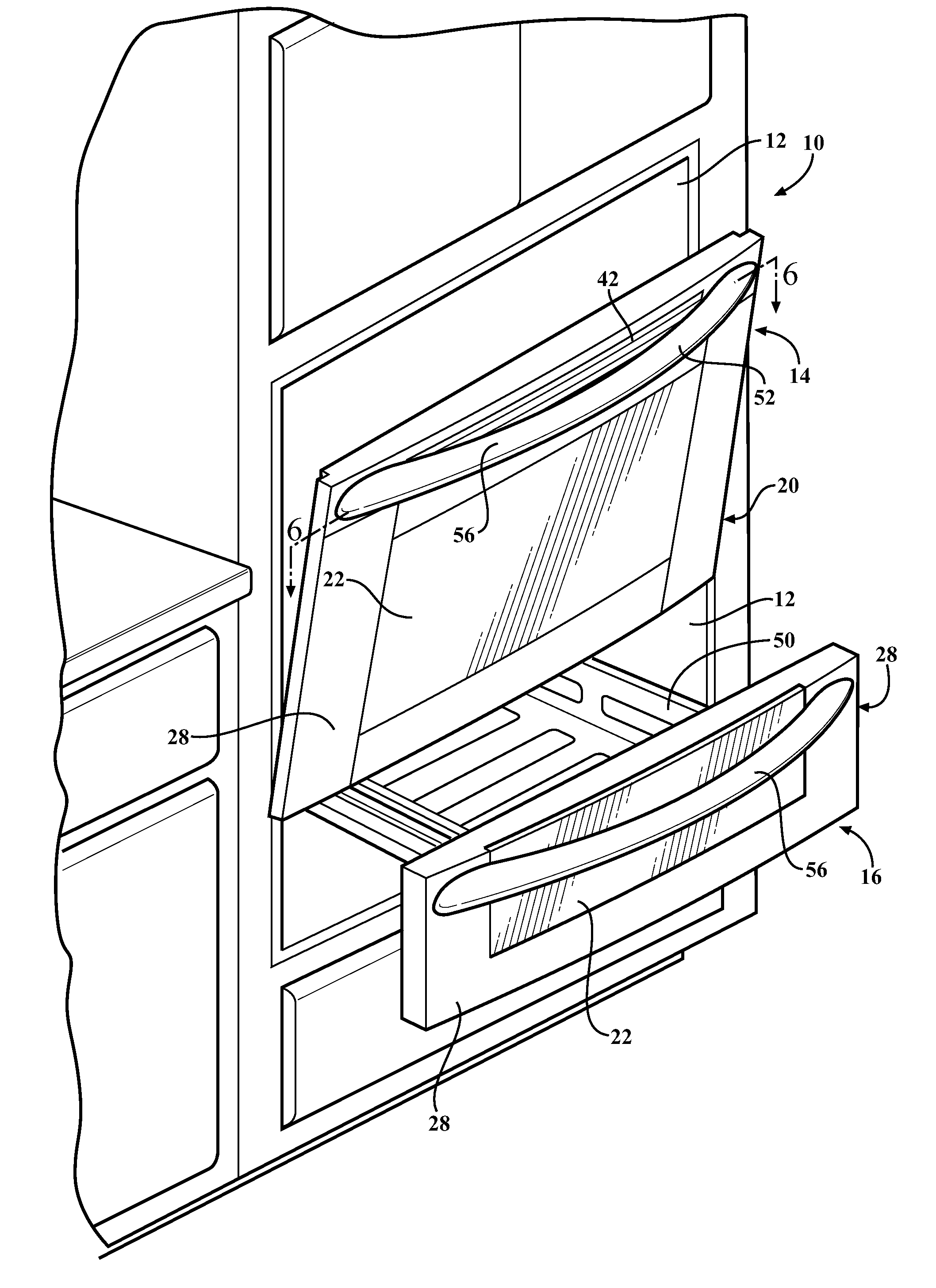

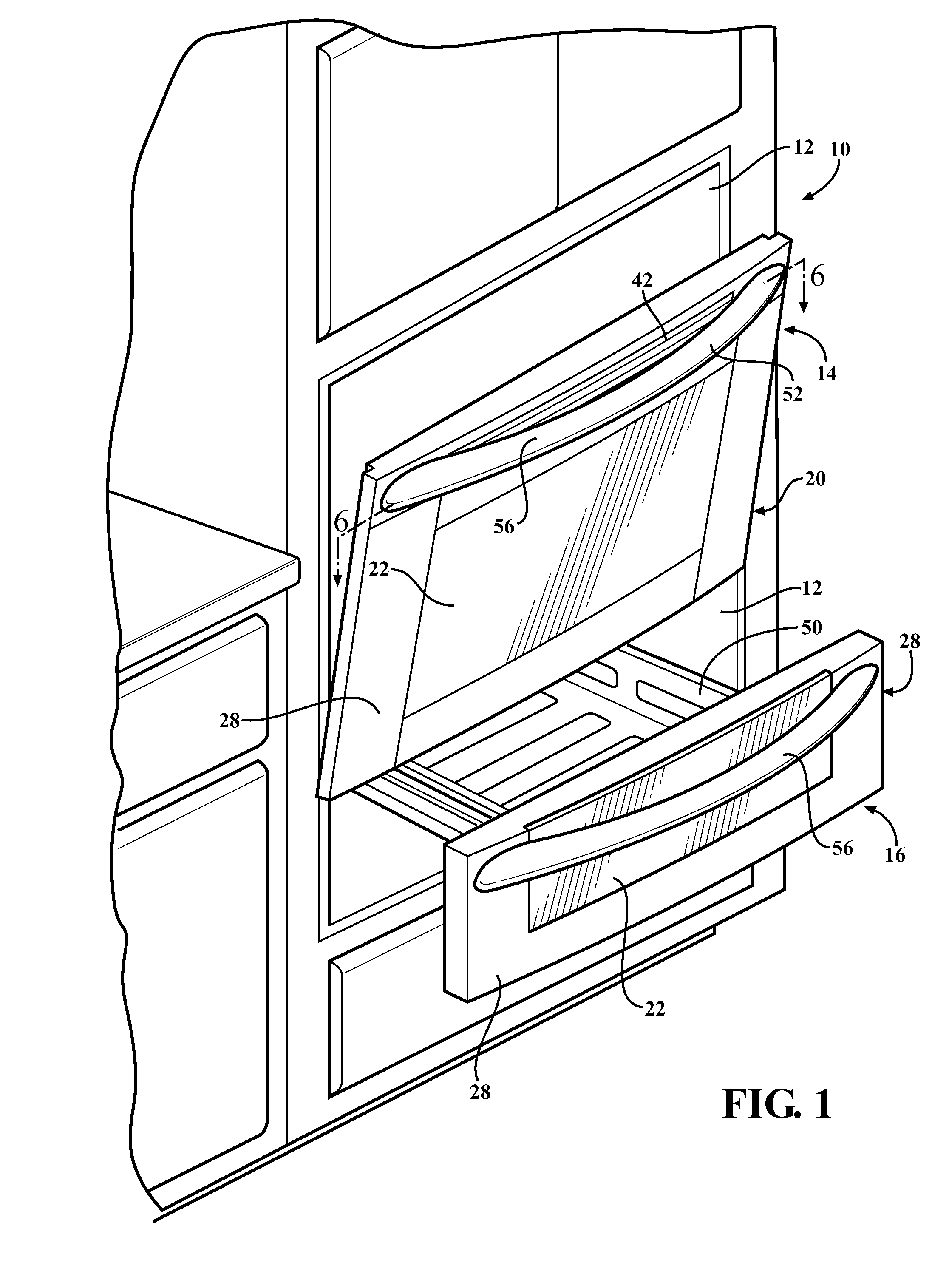

Oven door

a technology for ovens and doors, applied in the field of oven doors, can solve the problems of increasing the cost of exterior panels formed of stainless steel, increasing the cost of metal components and glass pane manufacturing, and relatively high material cost for manufacturing metal components and glass panes, etc., and achieves the effects of less cost, less material cost, and less cost of material and frame parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

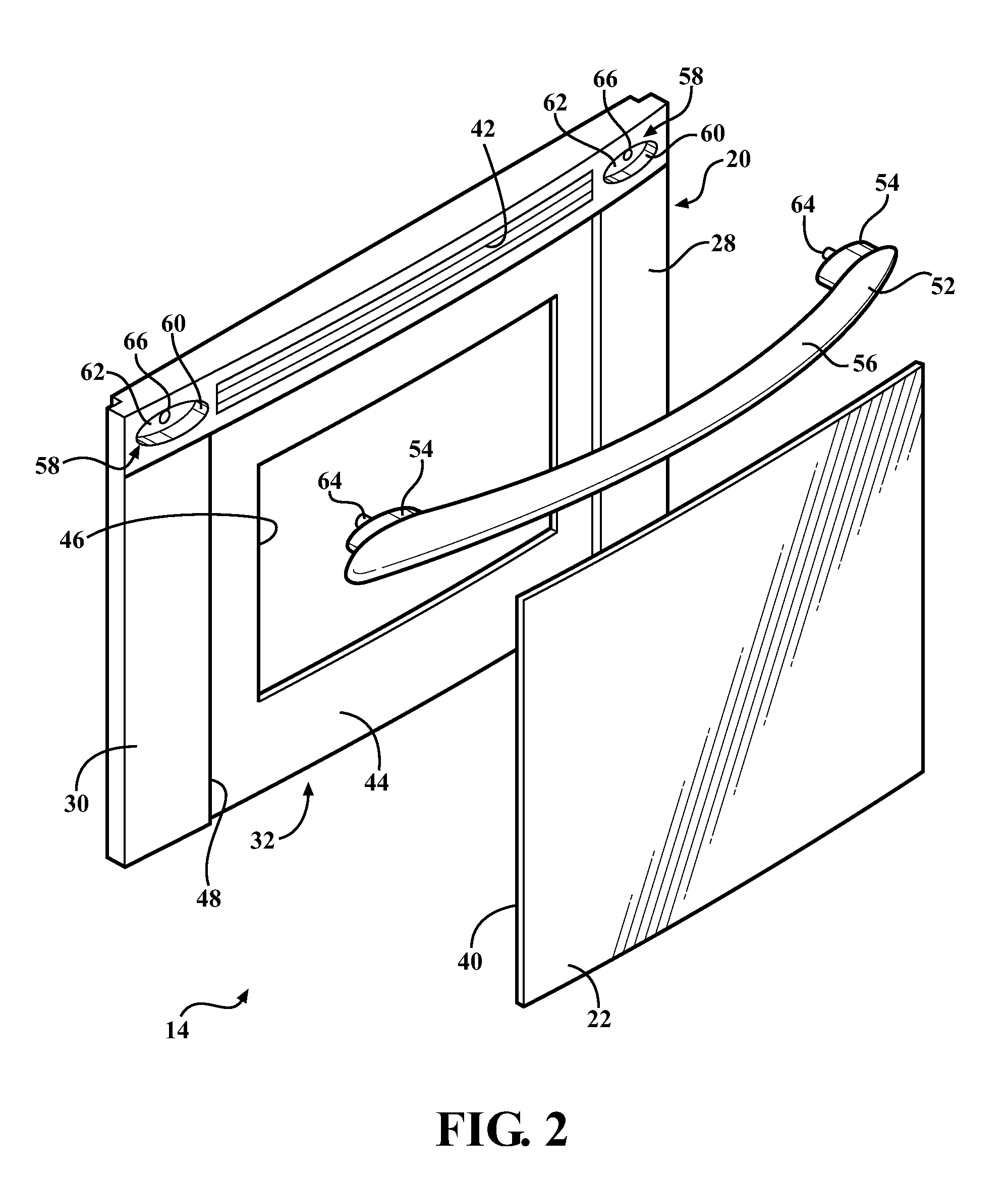

[0033]In the first oven door 14, with reference to FIGS. 2 and 3, the exterior panel 20 has a masking portion 44 typically formed of plastic. The masking portion 44 is typically integrally formed with the frame portion 30 as shown in FIGS. 2 and 3, i.e., formed together simultaneously or at substantially the same time so as to form a single part. Alternatively, the masking portion 44 is integrally formed with the non-opaque panel 22 such that the masking portion 44 and the non-opaque panel 22 in combination are assembled to the frame portion 30 in the aperture 32. In any event, the masking portion 44 extends from the frame portion 30 into the aperture 32 along the inside surface 40 of the non-opaque panel 22 and defines a window 46 for viewing the heating chamber 12 through the glass sheet of the interior panel 18.

[0034]The masking portion 44 is typically formed of the same type of plastic as the rest of the exterior panel 20 as set forth above. However, it should be appreciated tha...

second embodiment

[0041]With reference to FIG. 4, in the first oven door 14, the non-opaque panel 22 is integrally formed with the exterior panel 20, i.e., formed together simultaneously or at substantially the same time so as to form a single part. The non-opaque panel 22 is typically formed of plastic. The non-opaque panel 22 can be formed from the same type of plastic as that of the exterior panel 20 or can be formed from a different type of plastic than that of the exterior panel 20. The plastic can be glass filled or can be free of glass filling. One example of a type of suitable plastic for the non-opaque panel 22 is an unfilled polyethersufone commercially available from BASF Corporation in Florham Park, NJ under the tradename Ultrason® E2010. However, it should be appreciated that the non-opaque panel 22 can be formed of any type of suitable material without departing from the nature of the present invention.

[0042]In the second embodiment of the first oven door 14, the masking portion 44 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com