Rapid molding pattern carving glue and preparation method thereof

A fast, acrylic monomer technology, used in pedicures, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems affecting the overall effect of nail art, easy to break and damage, poor nail adhesion, etc., to achieve short curing time, increase adhesion, The effect of reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

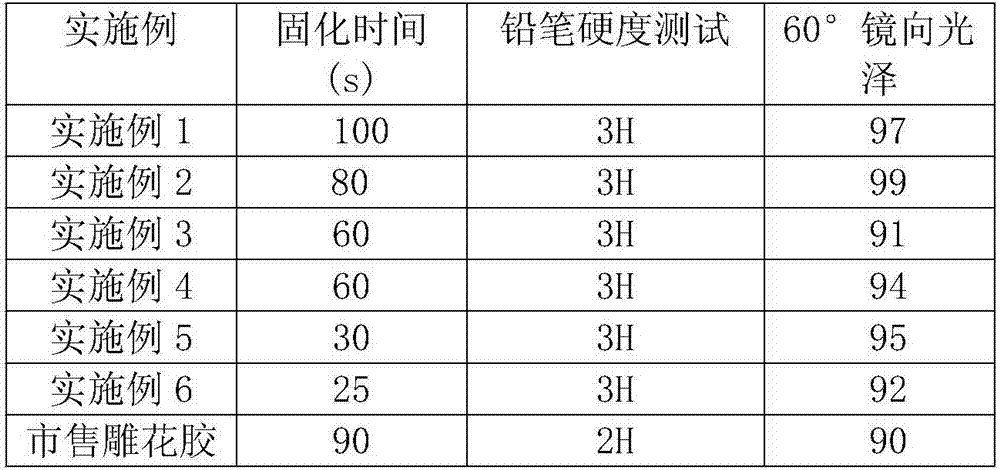

Examples

preparation example Construction

[0030] A kind of preparation method of quick-molded carved glue, is characterized in that, comprises the following steps:

[0031] a) Mix 35% to 45% wt of acrylic acid monomer / methacrylic acid monomer with 10% to 20% wt of polymerized rosin, heat up to 70-90°C in a water bath, and stir mechanically to make the acrylic acid monomer / methacrylic acid monomer The mixture of acrylic acid monomer and the polymerized rosin is uniformly dissolved and ready for use;

[0032] b) Add 35% to 45% wt of filler and 1% to 5% wt of colorant to the mixture described in step a), and mechanically stir to fully disperse;

[0033] c) adding 1% to 5% wt of photoinitiator, mechanically stirring, and mixing evenly to obtain the rapid prototyping carved glue;

[0034] There is no sequence for adding the fillers and colorants;

[0035] The polymerized rosin is B-100 polymerized rosin.

Embodiment 1

[0041] 35g of ethyl methacrylate was mixed with 15g of polymerized rosin B-100 (Shanghai Jiuqing Chemical Industry Co., Ltd.), the water bath was heated to 80°C, and mechanically stirred to make the mixture of said ethyl methacrylate and said polymerized rosin dissolve uniformly. stand-by;

[0042] b) Add 45g of nano-calcium carbonate and 4g of color paste to the mixture described in step a), and mechanically stir to fully disperse;

[0043] c) adding 1g of hydroxycyclohexyl phenyl ketone, mechanically stirring, and mixing evenly to obtain the rapid-forming engraved glue;

Embodiment 2

[0045] Mix 35g of hydroxypropyl methacrylate with 20g of polymerized rosin B-100 (Shanghai Jiuqing Chemical), heat up the water bath to 80°C, and stir mechanically to dissolve the mixture of the hydroxypropyl methacrylate and the polymerized rosin Uniform, ready to use;

[0046] b) Add 40g of nano-calcium carbonate and 3g of color paste to the mixture described in step a), and mechanically stir to fully disperse;

[0047] c) adding 2g of hydroxycyclohexyl phenyl ketone, mechanically stirring, and mixing evenly to obtain the rapid-forming engraved glue;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com