Water-based paint suitable for continuous production of pencils and preparation method thereof

A kind of water-based paint, water-based technology, applied in the direction of coating, polyurea/polyurethane coating, etc., can solve the problem of uneven paint surface, speed up the drying speed of water-based paint, and the gloss and adhesion of pencil paint film need to be improved, so as to eliminate Effects of adverse factors, good adhesion and gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

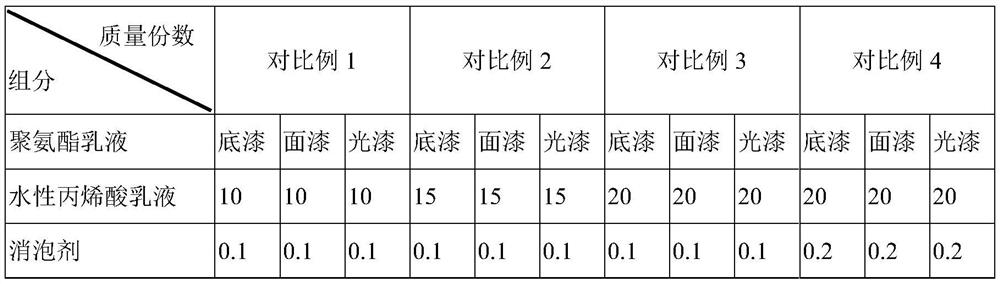

[0040] A kind of water-based paint suitable for the continuous production of pencils, the preparation steps of the primer are: according to weight percentage, weigh 10 parts of polyurethane emulsion, 10 parts of water-based acrylic emulsion, 15 parts of water-based acrylic resin, 15 parts of deionized water, and mix uniformly and stir Minutes, then add 0.1 part of defoamer, 3 parts of film-forming aids, 0.5 part of diethanolamine, 10 parts of talcum powder, at a temperature of under stirring Minutes, first dissolve 0.01 part of dibutyltin dilaurate into 15 parts of 95% ethanol, and then add to the above mixture; then add 18 parts of water-based color paste, 2 parts of covering polymer, and stir minute. After mixing well, a primer is obtained.

[0041] The preparation steps of the topcoat are: according to weight percentage, weigh 10 parts of polyurethane emulsion, 10 parts of water-based acrylic emulsion, 15 parts of water-based acrylic resin, and 15 parts of deionized ...

Embodiment 2

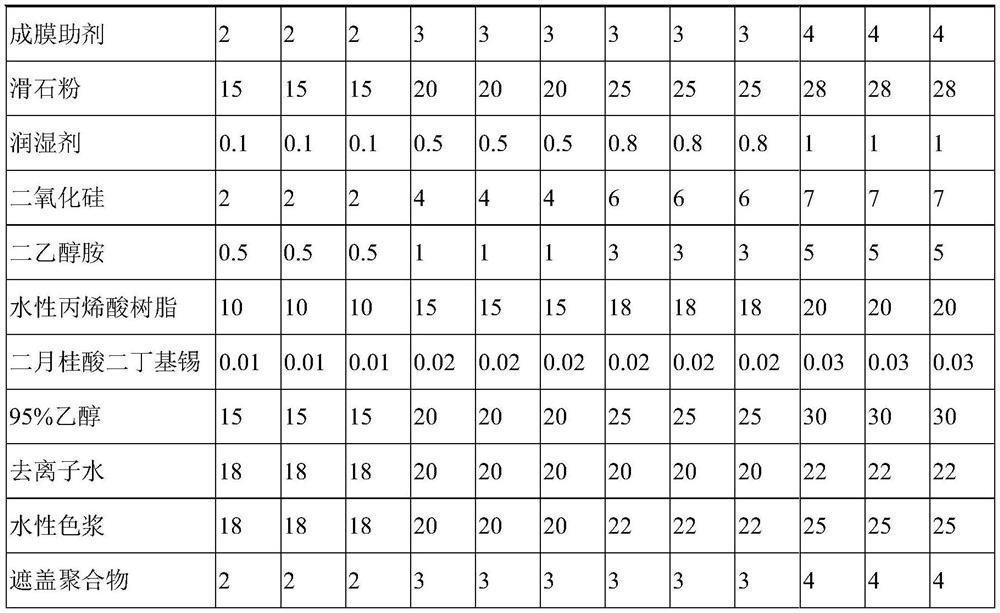

[0058] Screening of drying aids

[0059] The preparation method of water-based paint is the same as in Example 1. Except the type of drying aid in the formula, the types and contents of other components are the same as in Comparative Example 3. The influence of different drying aids on the performance of pencil water-based paint is investigated. The results are as follows: table 3.

[0060] Table 3 Effects of different types of drying aids on the performance of water-based paints

[0061]

[0062]

[0063] It can be seen from the above table that dibutyltin dilaurate not only has obvious drying aid effect, but also has no adverse effect on adhesion and gloss, and its performance is obviously better than other drying aids.

Embodiment 3

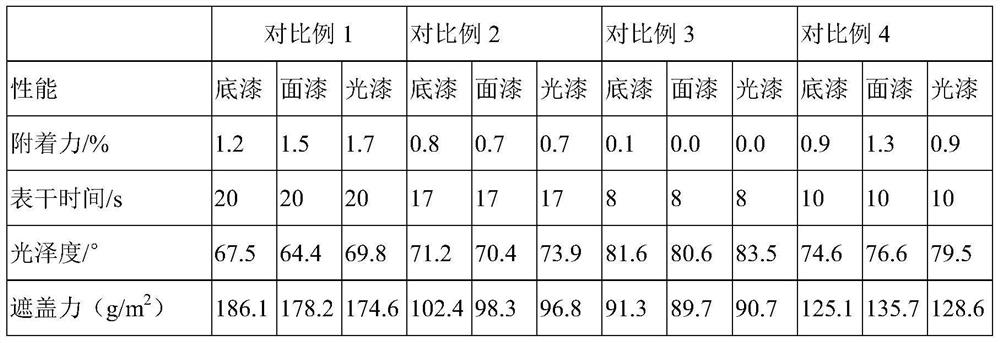

[0065] The influence of ethanol concentration on the performance, the preparation method and content of the water-based paint are the same as in Comparative Example 3, and the influence of different concentrations of ethanol on the performance of the water-based paint is investigated, and the results are shown in Table 4.

[0066] The impact of table 4 ethanol concentration on the performance of water-based paint

[0067]

[0068] It can be seen from Table 4 that the higher the ethanol concentration is not the better, the surface drying time will be faster if the concentration is higher than 95%, but other properties will be reduced. Therefore, considering comprehensively, ethanol with a concentration of 95% is optimal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com