Self-leveling dry powder mortar and preparation method thereof, terrace manufactured from dry powder mortar, and construction method of terrace

A dry-mixed mortar and self-leveling technology, used in buildings, building structures, floors, etc., can solve the problems of unstable quality, easy bursting, and material inconsistency of on-site mixing mortar, so as to reduce labor and machine equipment costs. High compressive strength and density, toughness and crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

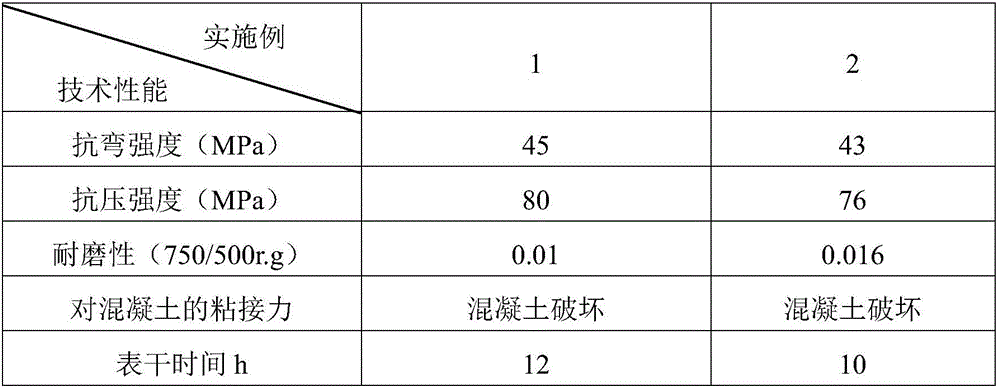

Embodiment 1

[0021] Raw materials: Ordinary Portland cement 42%, 4-8 mesh quartz sand 12%, 10-30 mesh quartz sand 30%, 60-140 mesh quartz sand 10%, methyl cellulose MT400 0.1%, dispersible latex powder 5111L 2%, superplasticizer F10 0.4%, defoamer P803 0.4%, rutile titanium dioxide 0.6%, and high-strength and high-modulus polyvinyl alcohol fiber 2.5%.

[0022] The preparation method includes: mixing 4-8 mesh quartz sand, 10-30 mesh quartz sand, and 60-140 mesh quartz sand for 2 minutes, adding ordinary Portland cement, methyl cellulose MT400, dispersible latex powder 5111L, high-efficiency reducing Water agent F10, defoamer P803, rutile titanium dioxide and high-strength and high-modulus polyvinyl alcohol fiber are mixed for 25 minutes to prepare dry powder mortar.

Embodiment 2

[0024] The preparation method is the same as that of Example 1, except that the components and contents of the raw materials are: 48% of ordinary Portland cement, 8% of 4-8 mesh emery aggregate, 20% of 10-30 mesh quartz sand, 60 -140 mesh quartz sand 20%, methyl cellulose HPMC-500 0.05%, dispersible latex powder 5011L 1%, superplasticizer F10 0.2%, defoamer P803 0.2%, rutile titanium dioxide 0.55% and high strength and high modulus Vinyl fibers 2%.

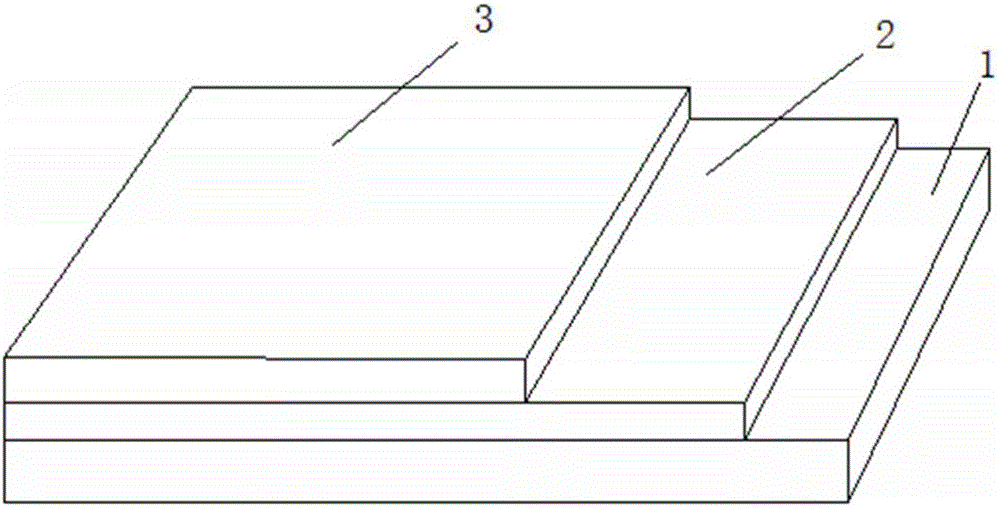

[0025] As shown in Figure 1, the surface layer type self-leveling floor is made by using the dry powder mortar provided in Example 1-2, which includes a base surface 1, an interface layer 2 and a cement-based self-leveling floor 3 from bottom to top.

[0026] The construction method of the floor of the present invention includes: mixing the interface agent styrene-acrylic polymer emulsion 5181 and water according to the mass ratio of 1:6 and 1:3 respectively, and then infiltrating them on the base surface sequentially to form an i...

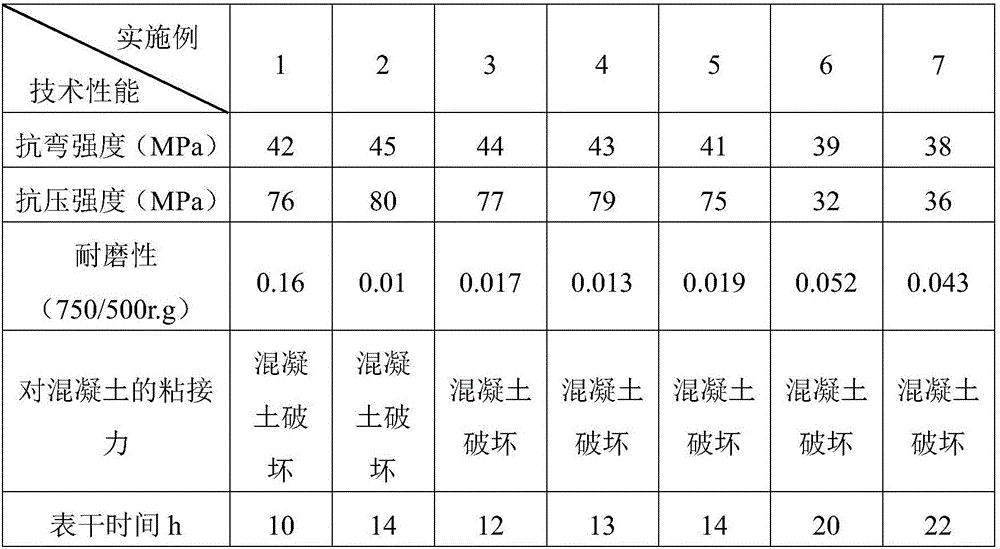

Embodiment 3

[0032] Design 7 groups of parallel experiments, basic steps are identical with embodiment 1, difference is the component content of raw material, is respectively:

[0033] 1. Ordinary Portland cement 40%, 4-8 mesh alumina aggregate 11%, 10-30 mesh quartz sand 26.32%, 60-140 mesh quartz sand 18%, methyl cellulose MT400 0.08%, dispersible latex Powder 5111L 1.5%, superplasticizer F100.3%, defoamer P803 0.3%, rutile titanium dioxide 0.3%, and high-strength and high-modulus polyvinyl alcohol fiber 2.2%;

[0034] 2. Ordinary Portland cement 42%, 4-8 mesh alumina aggregate 12%, 10-30 mesh quartz sand 30%, 60-140 mesh quartz sand 10%, methyl cellulose MT400 0.1%, dispersible latex Powder 5111L 2%, superplasticizer F10 0.4%, defoamer P803 0.4%, rutile titanium dioxide 0.6%, and high-strength and high-modulus polyvinyl alcohol fiber 2.5%;

[0035]3. Ordinary Portland cement 45%, 4-8 mesh alumina aggregate 11%, 10-30 mesh quartz sand 24%, 60-140 mesh quartz sand 14.72%, methyl cellulos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com