Yellow cadmium-wrapped pigment, ceramic ink and preparation method thereof

A technology for wrapping colorants and ceramic inks, applied in the directions of copying/marking methods, chemical instruments and methods, inks, etc., can solve the problems of cadmium-based colorants being not environmentally friendly and not resistant to high temperature, so as to avoid clogging screen holes and Inkjet holes, fineness reduction, high chromaticity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

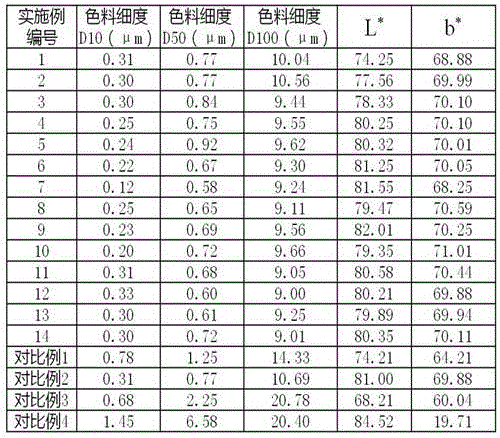

Examples

preparation example Construction

[0028] Concrete preparation method is as follows steps:

[0029] Step ① Weigh cadmium sulfate (CdSO 4 •8H 2 O) and zirconium oxychloride (ZrOCl 2 •8H 2 O), add water to dissolve; the added quality of water is 3-5 times of the weight of the solid.

[0030] ② Weigh urea and thiourea according to the formula table, and add water to dissolve; the added quality of water is 5-10 times of the weight of solid matter.

[0031] ③ Weigh the dispersant polycarboxylate and PVP according to the formula table, and dissolve them in 2000-2500ml of water.

[0032] ④Mix the solutions in steps ①-③, add the silicon source, and mix evenly; in this step, ultrasound can be used to assist dispersion.

[0033] ⑤Pour the mixed reaction solution in step ④ into the reaction kettle, adjust the temperature to 60-200°C, the rotation speed to 100-300r / min, and react for 5-24h.

[0034] ⑥ Take out the reaction precursor obtained in step ⑤, wash with water, filter with suction, and dry.

[0035] ⑦ Mix the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com