Patents

Literature

52results about How to "Control process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

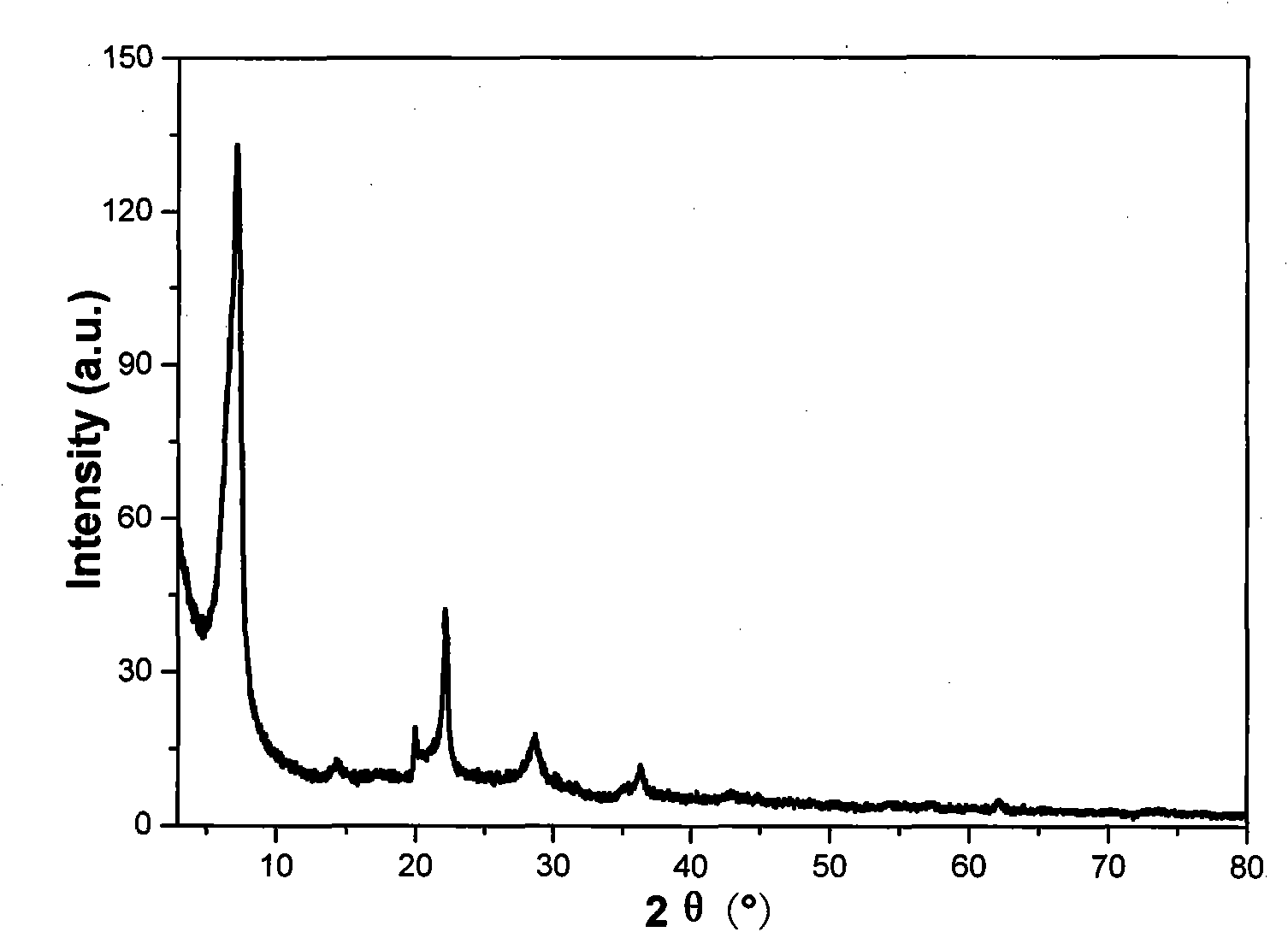

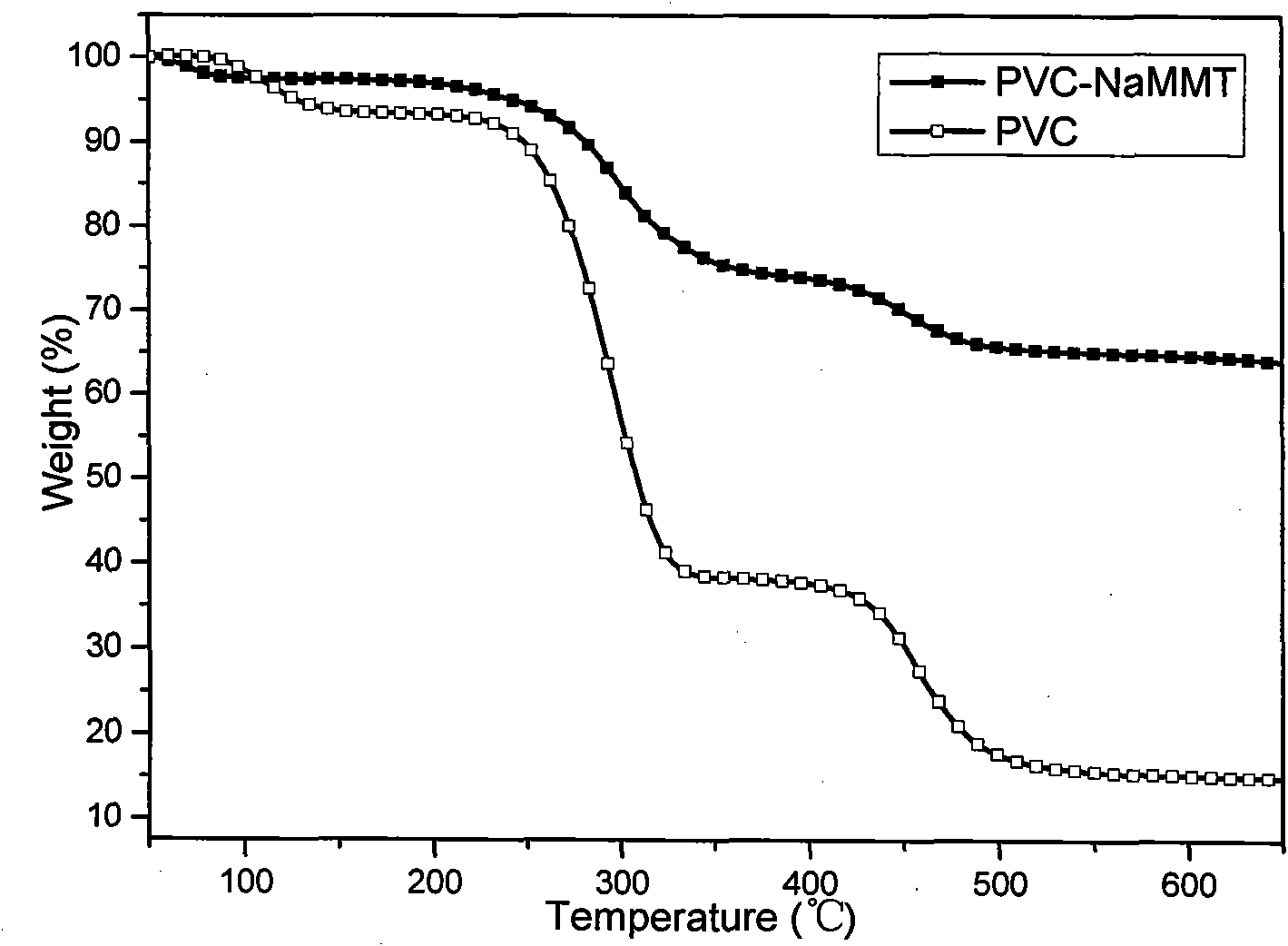

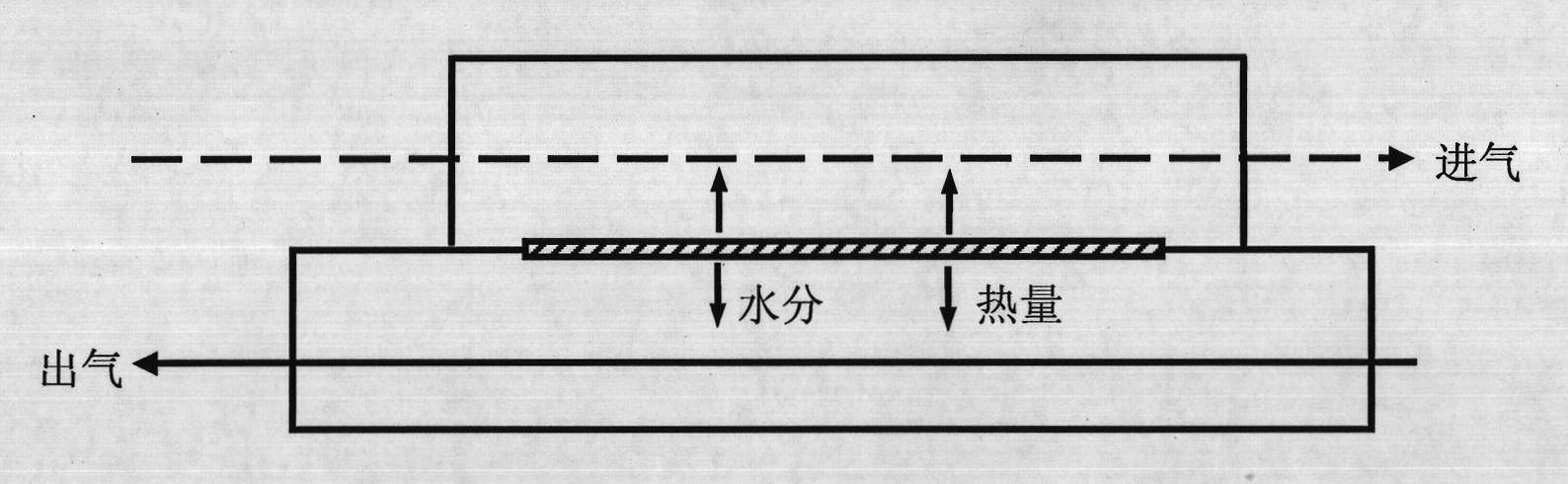

Diathermanous and moisture permeable composite film and preparation method thereof

ActiveCN102061026AHigh heat transfer and moisture permeabilityImprove thermal conductivitySolubilityComposite film

The invention discloses a composite fast ion conductive film which has diathermanous and moisture permeable performance and is used as a diathermanous and moisture permeable composite film. The composite fast ion conductive film comprises high polymer, silicate and additive, wherein the silicate is dispersed in the high polymer in a crystalline phase particle to form a multiphase solid film; the high polymer has solubility or fusibility, the silicate has lamellar or porous structure; and according to the weight percentage, the content of the high polymer is 10%-80%, the content of the silicate is 10%-90% and the content of the additive is 0%-30%. Compared with the prior art, the diathermanous and moisture permeable composite film, the fast ion conductive film has low cost, simple process, good heat conduction and moisture penetrability, and good application prospect in the air heat exchanger field.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

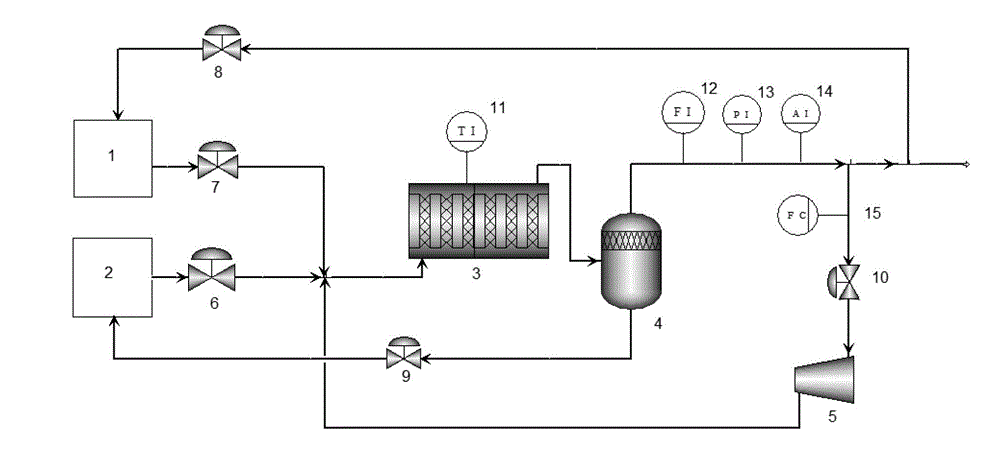

CO2 enrichment and methanation process in sealed space and reactor

ActiveCN104152197AImprove balance limitsLower balance limitHydrocarbon from carbon oxidesGaseous fuelsChemistrySubmarine

The invention relates to a CO2 enrichment and methanation process in a sealed space and a CO2 enrichment and methanation reactor. The CO2 enrichment and methanation process is mainly technically characterized in that the content of CO2 inside the sealed space can be effectively controlled and oxygen essential for survival can be provided. The CO2 enrichment and methanation reactor is compact in structure, CO2 enrichment and methanation reaction are integrated, and thus a CO2 desorption process used inside the sealed space is greatly simplified. By adopting the CO2 enrichment and methanation process and the CO2 enrichment and methanation reactor, CO2 inside the sealed space (in an underwater submarine and a space station) can be efficiently desorbed, and oxygen essential for survival is provided, so that the life and property security of human beings in working in space capsules or submarines is ensured.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

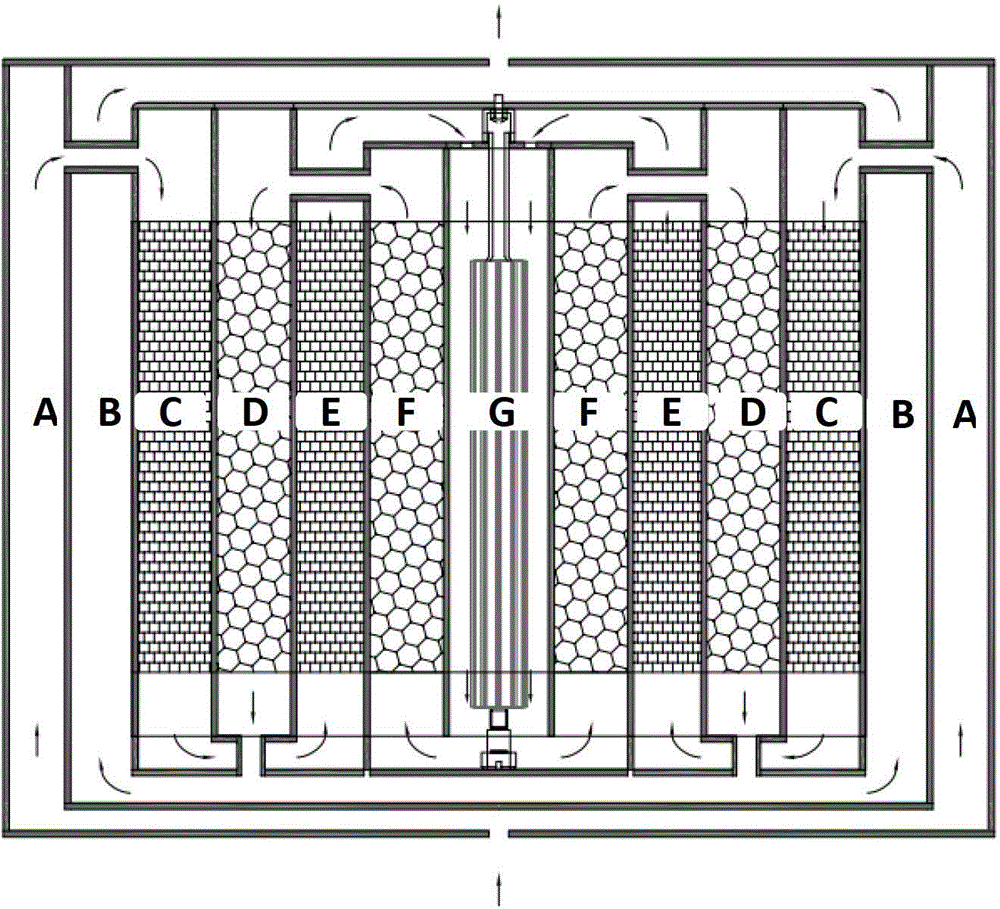

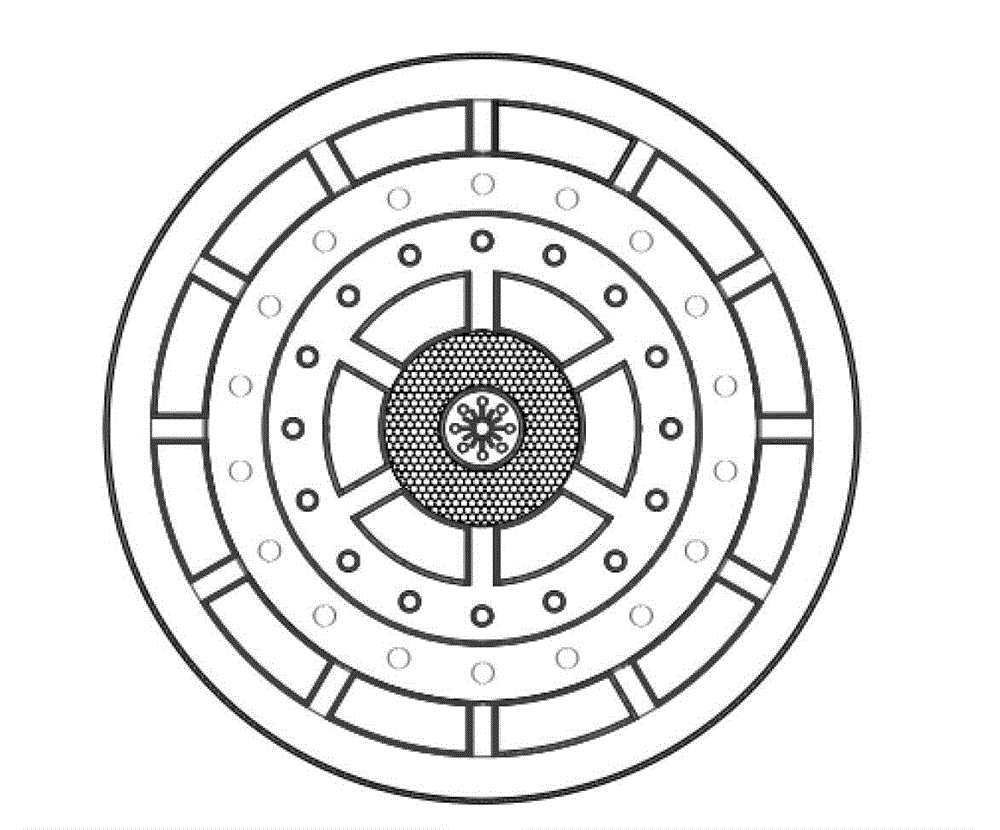

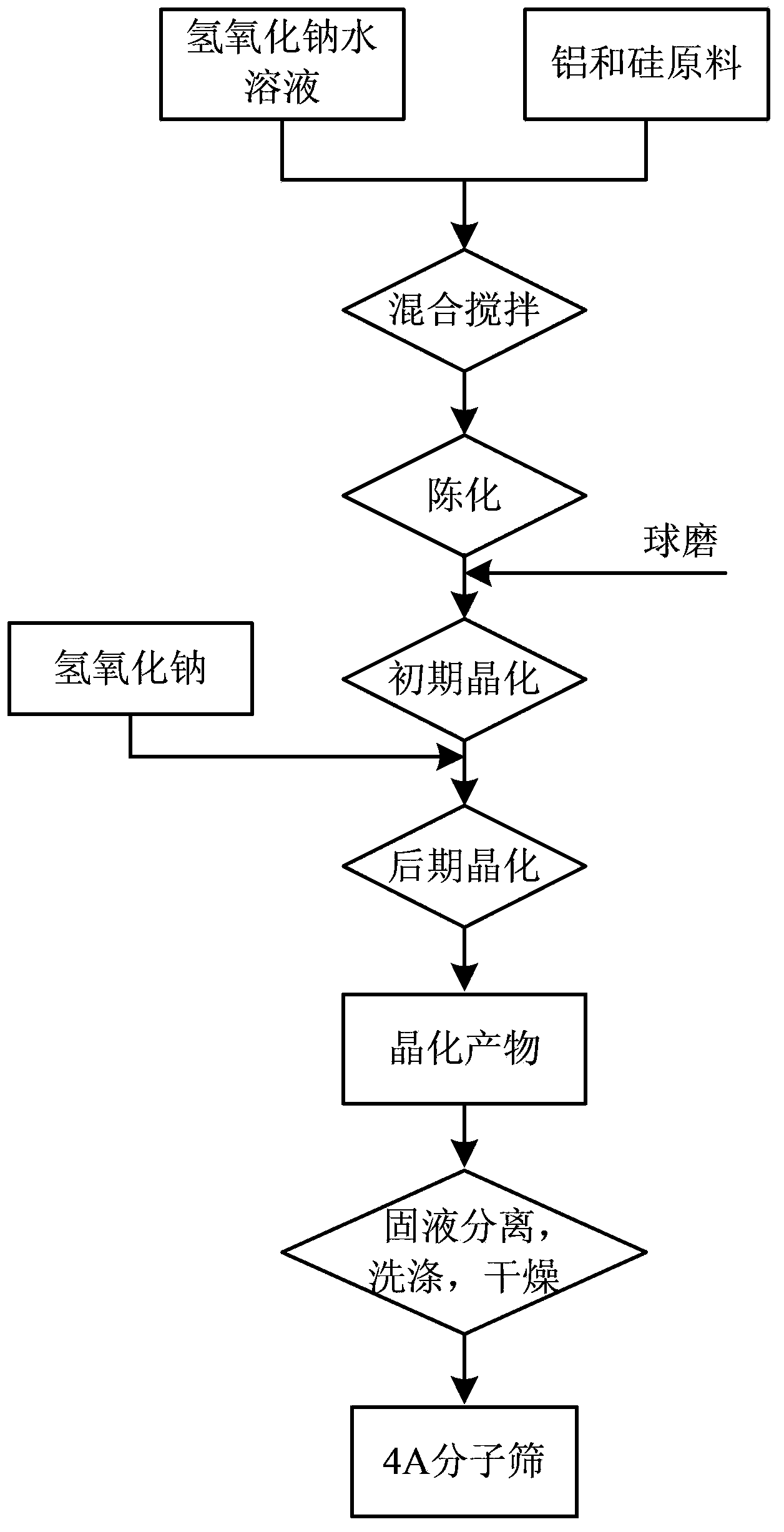

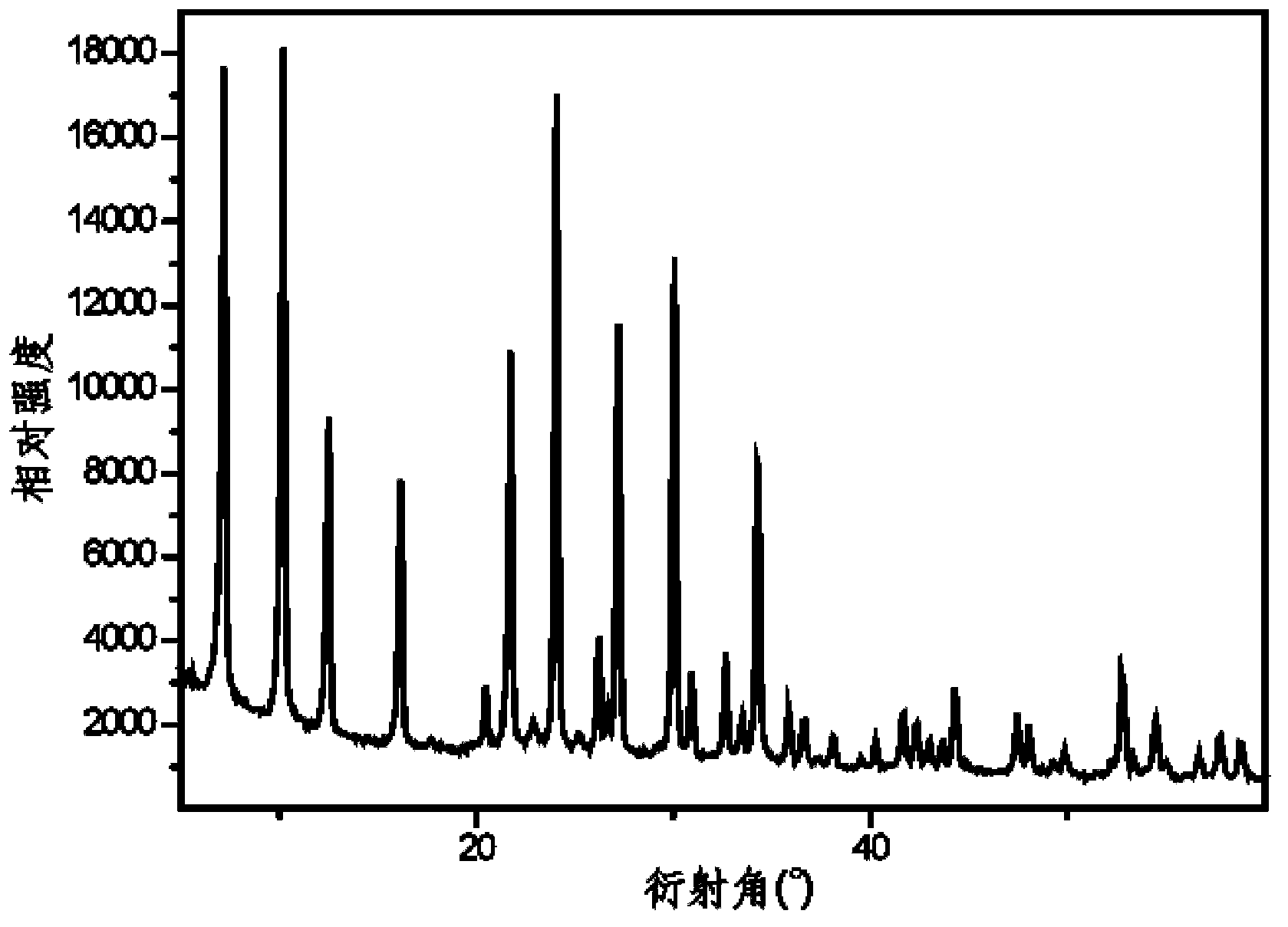

Hydrothermal synthesis method of 4A molecular sieve

ActiveCN104340989AHigh solid phase yieldHigh solid contentAluminosilicate zeolite type-AMolecular sieveWastewater

The invention relates to a hydrothermal synthesis method of a 4A molecular sieve. The hydrothermal synthesis method is characterized in that a ratio of water to sodium is not more than 25, and mechanochemical treatment is carried out. The preparation method of the 4A molecular sieve improves the solid phase yield of the hydrothermal synthesized 4A molecular sieve, guarantees the phase purity of the 4A molecular sieve, reduces the amount of water and the emission of wastewater, and also reduces the device and personnel investment.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

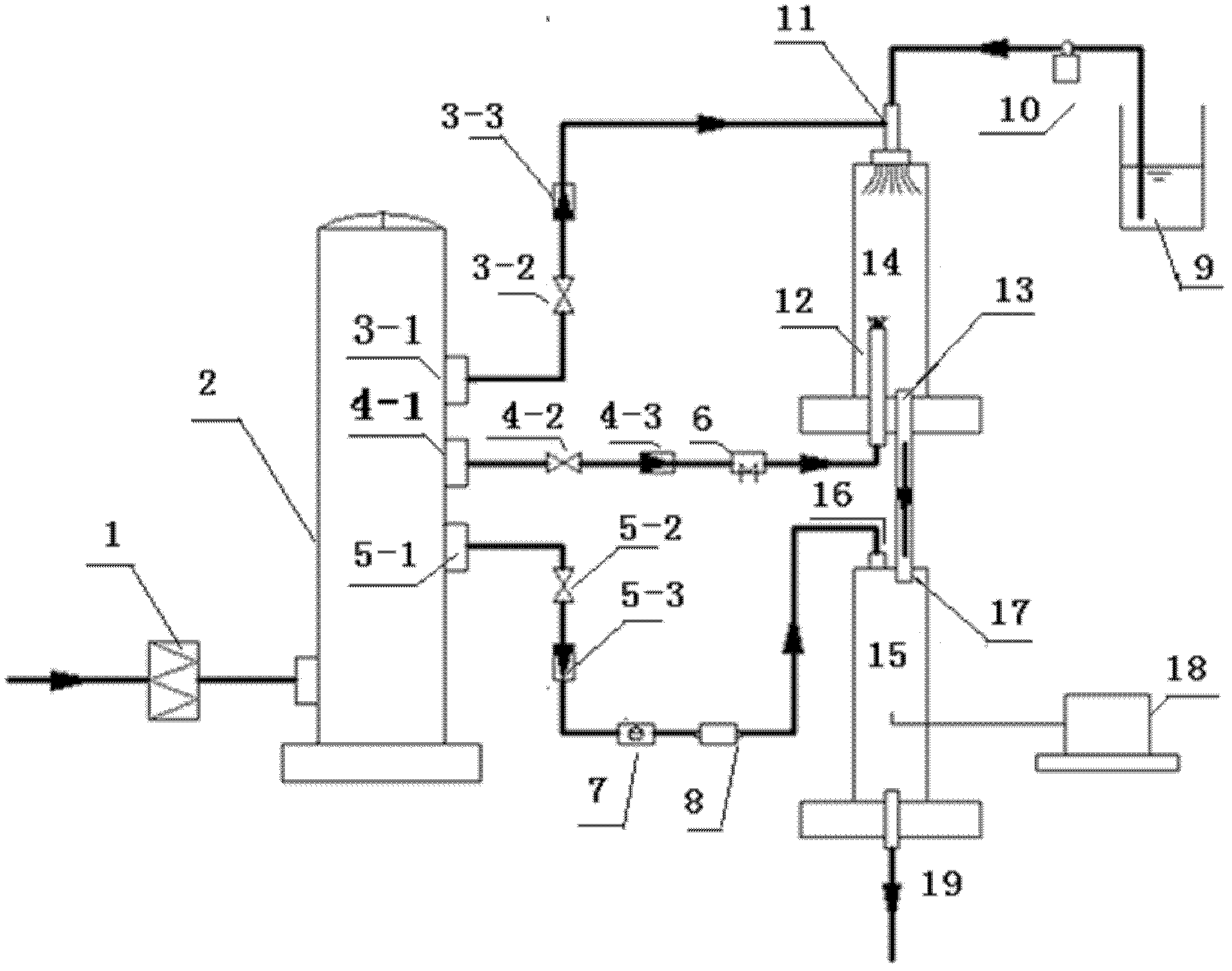

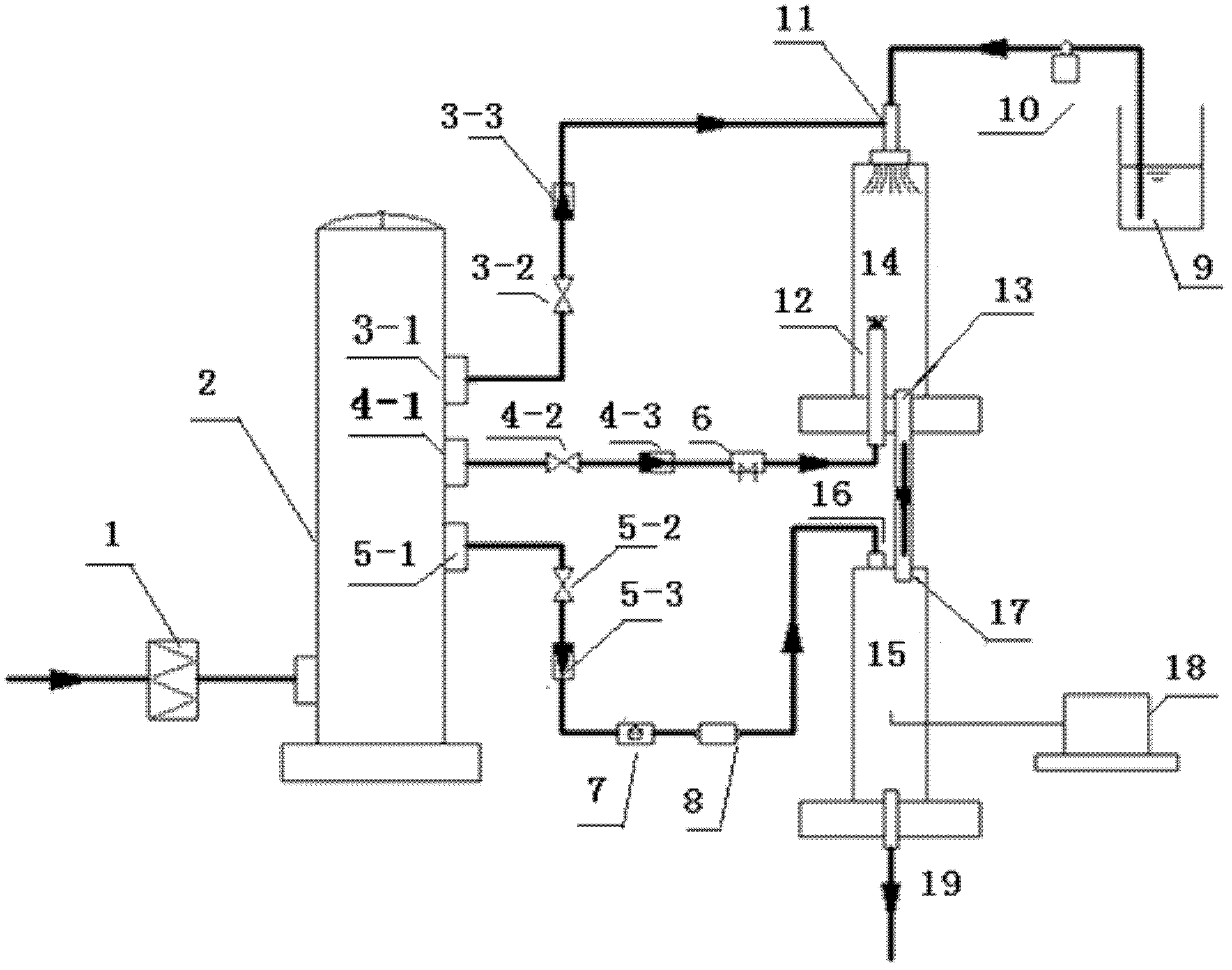

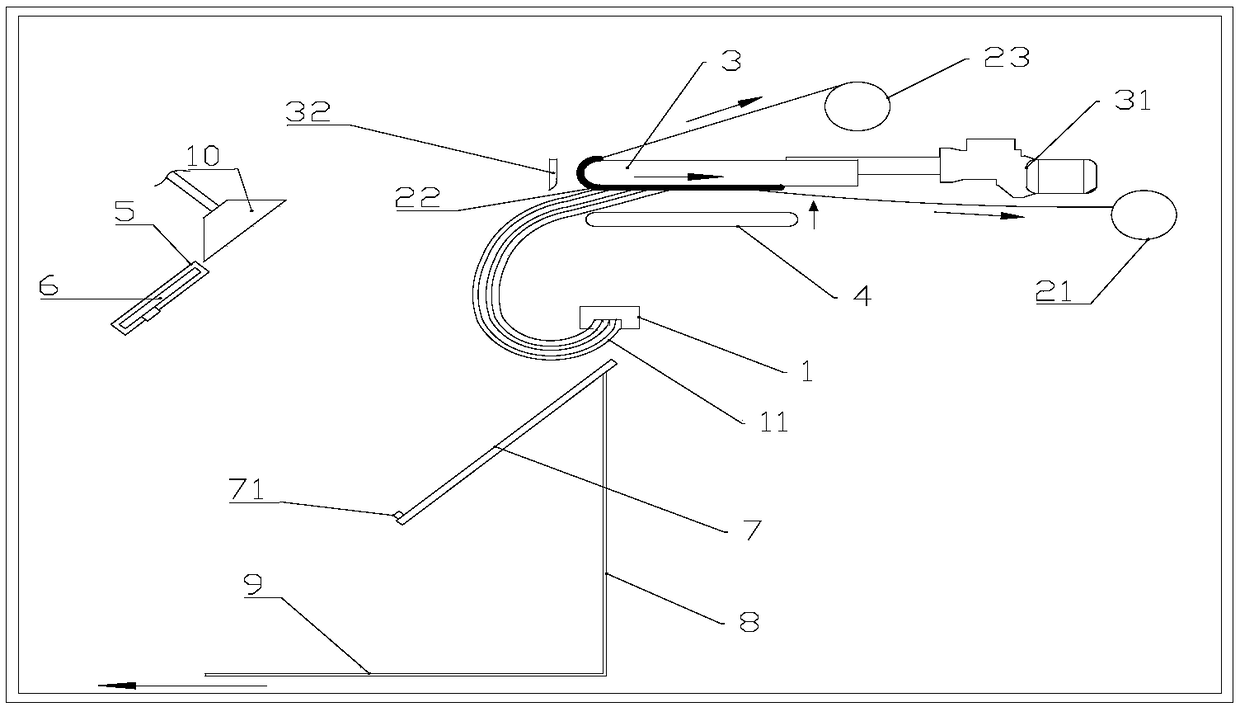

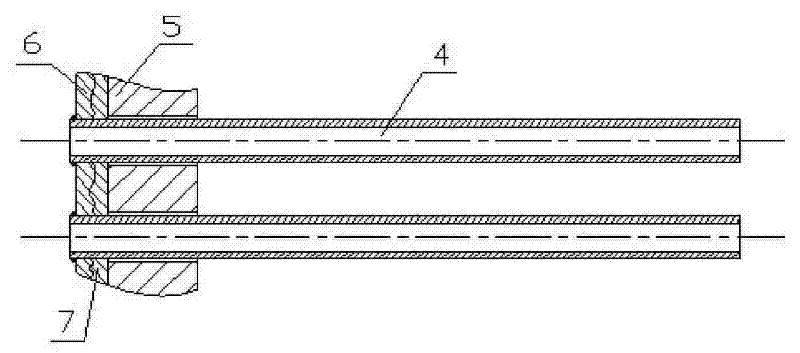

Potassium chloride aerosol generation method and potassium chloride aerosol generation device

InactiveCN102641699APerformance is easy to evaluate reasonablyControl processColloidal chemistry detailsAerosolizeEngineering

The invention provides a potassium chloride aerosol generation method and a potassium chloride aerosol generation device. The potassium chloride aerosol generation device comprises a gas storage cylinder, an atomizing chamber and potassium chloride solution. The gas storage cylinder is used for storing filtered and purified gas and connected with two pipelines. The first pipeline is connected to a nozzle arranged at the top of the atomizing chamber. The potassium chloride solution is connected to the nozzle through a solution pump. The second pipeline is provided with an air heater and is connected to a hot air outlet at the bottom of the atomizing chamber through a pipe. The gas storage cylinder is further connected with a third pipeline, and the third pipeline is connected with an air cooler and an air dryer, and is connected to the top of a condensing chamber through a pipe finally. The bottom of the atomizing chamber is connected to the top of the condensing chamber through a pipe, and an aerosol outlet is arranged at the bottom of the condensing chamber. With the potassium chloride aerosol generation device, moisture evaporation of liquid potassium chloride drops and crystallization of potassium chloride aerosol are realized respectively, the potassium chloride aerosol generation process can be controlled more accurately, and potassium chloride aerosol generated finally is guaranteed to be free of moisture.

Owner:周斌

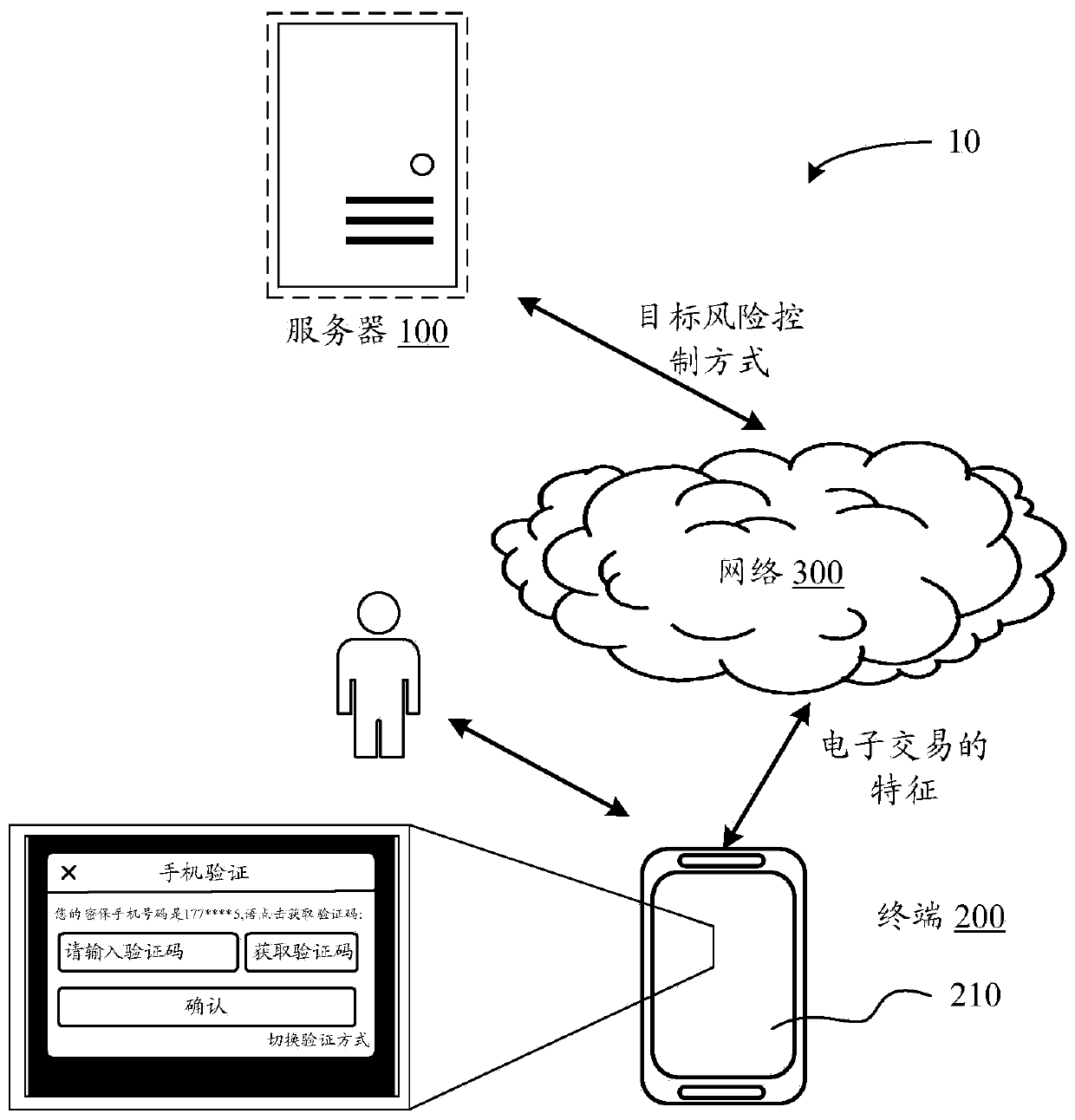

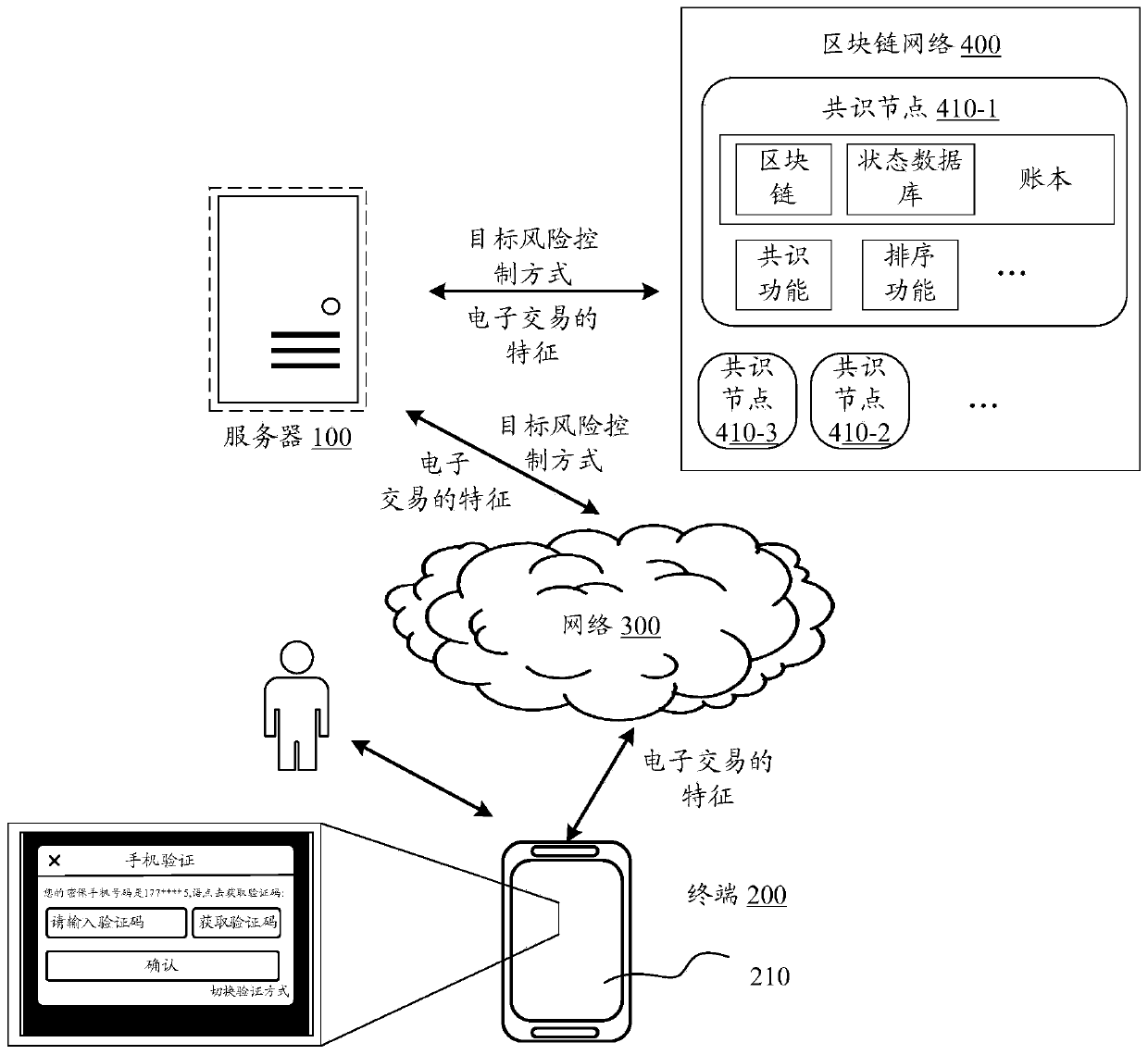

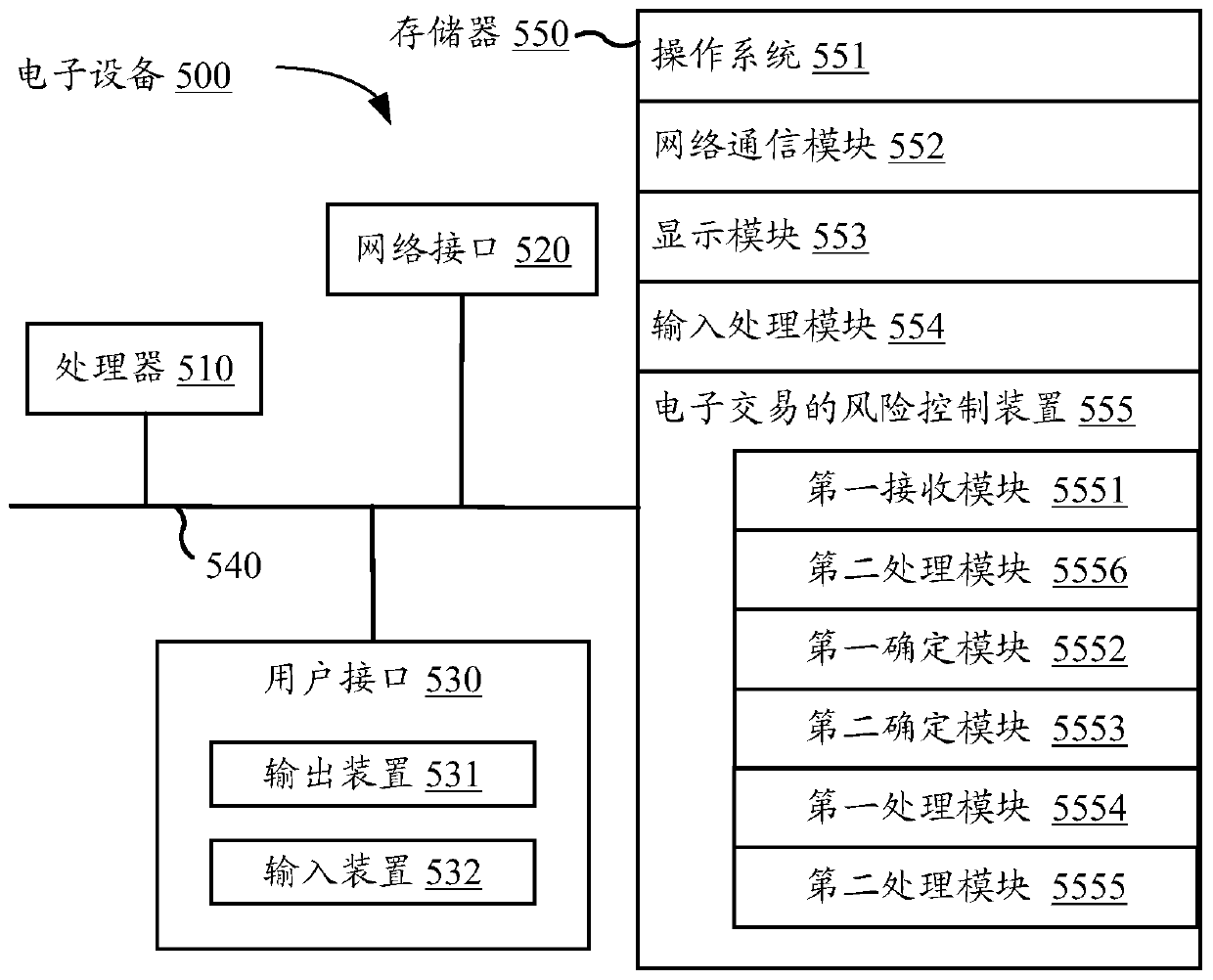

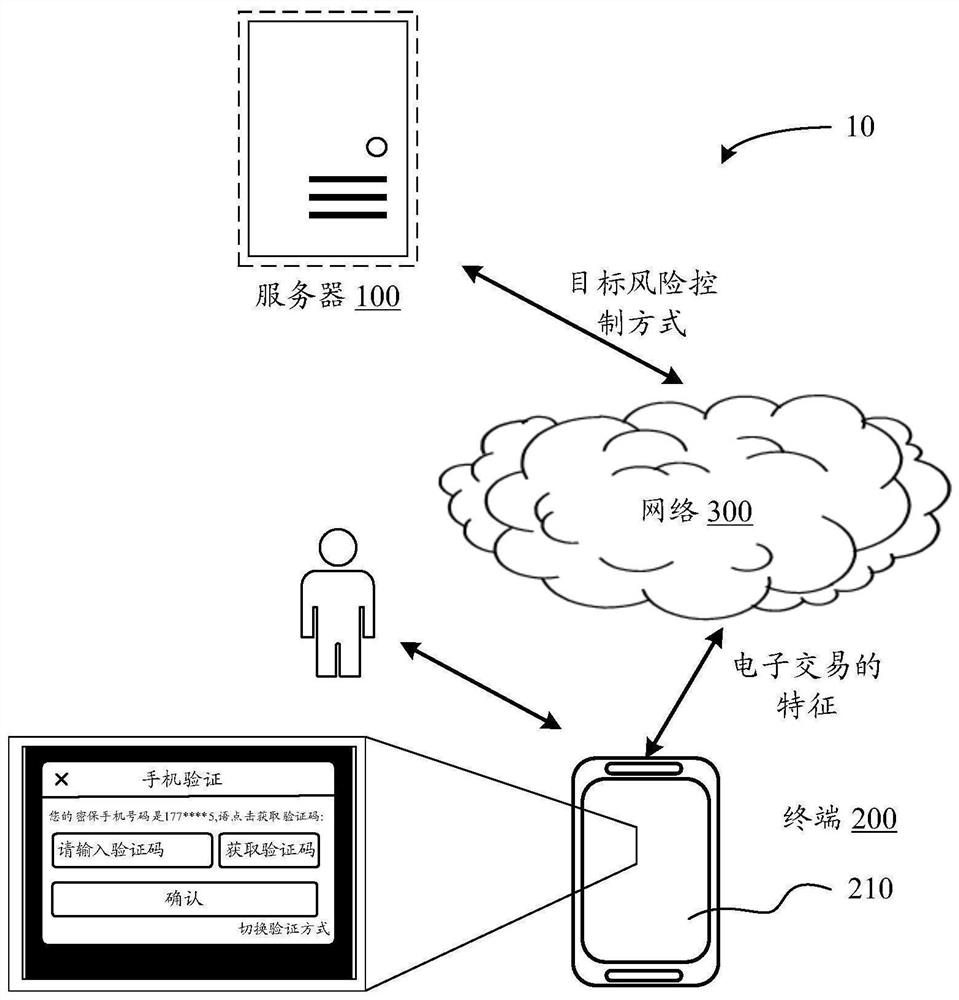

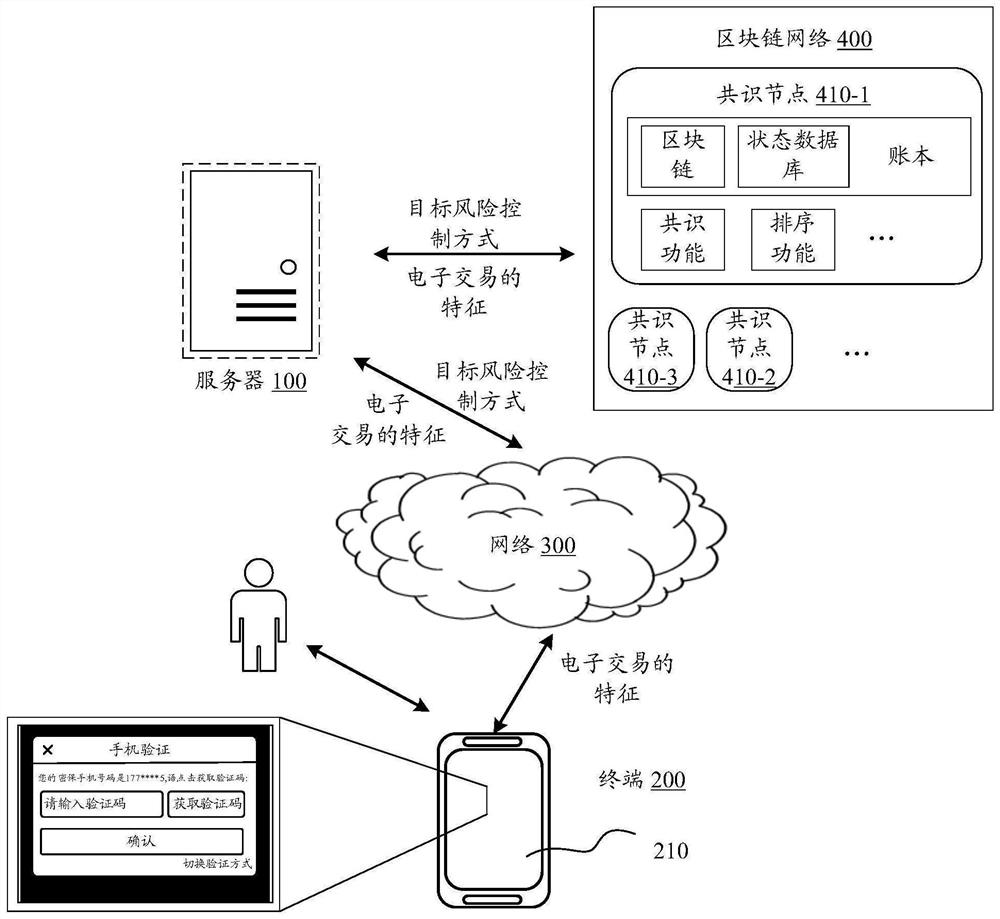

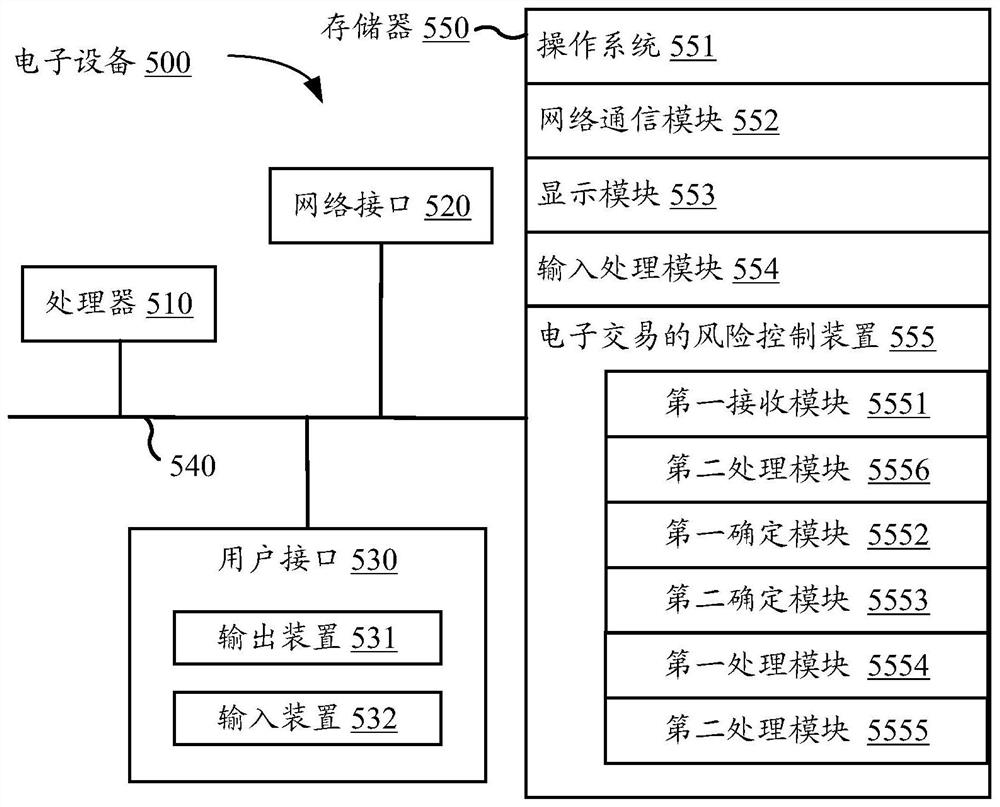

Risk control method and device for electronic transaction and electronic equipment

ActiveCN111429145AControl processReduce fratricideBuying/selling/leasing transactionsMarketingRisk ControlRisk level

The invention provides an electronic transaction risk control method and device, electronic equipment and a computer readable storage medium. The method comprises the steps of receiving feature information of an electronic transaction performed in a client; determining a risk scene where the electronic transaction is located based on the feature information, and determining a risk level of the electronic transaction in the risk scene; in a plurality of risk control modes corresponding to the risk scene, determining a risk control mode matched with the risk level of the electronic transaction to serve as a target risk control mode for controlling the electronic transaction; and applying the target risk control mode to an electronic transaction performed in the client, so as to delay the process of the electronic transaction in a risk scene where the electronic transaction is located. According to the invention, the process of the electronic transaction can be effectively controlled, andthe accidental injury rate of the electronic transaction is reduced.

Owner:SHENZHEN TENCENT COMP SYST CO LTD

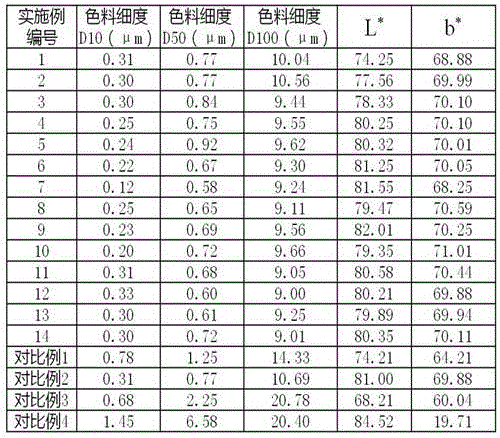

Yellow cadmium-wrapped pigment, ceramic ink and preparation method thereof

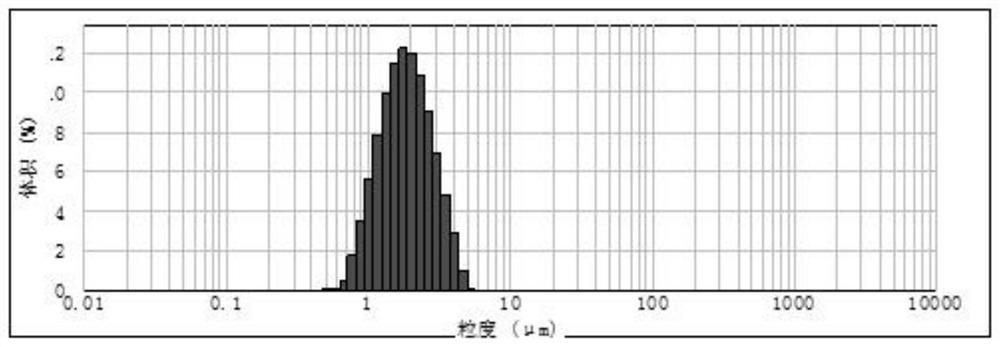

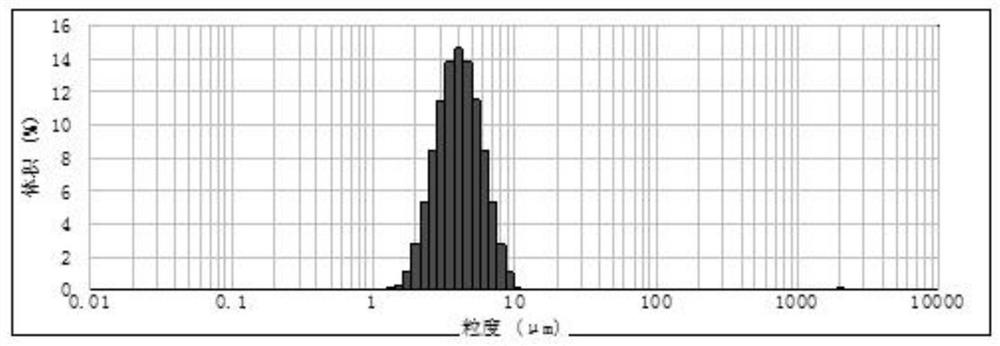

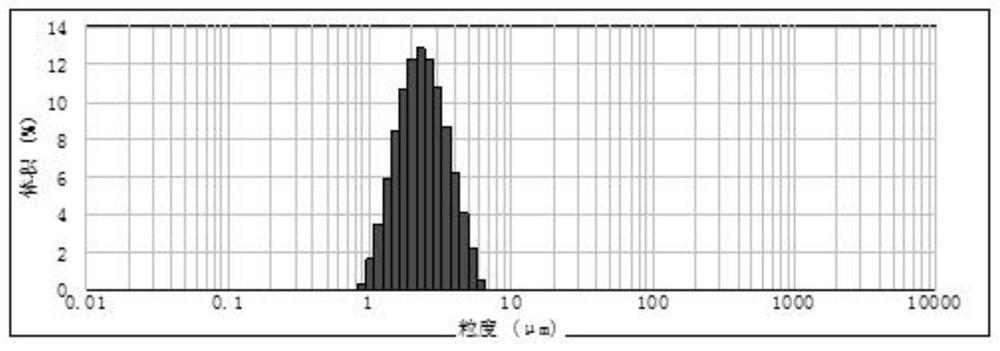

The invention discloses a yellow cadmium-wrapped pigment. The fineness of pigment powder is 0.5 to 3 [mu]m. The invention further provides a method of the yellow cadmium-wrapped pigment. The method comprises the following steps: putting cadmium sulfate, zirconium oxychloride, thiourea, urea, white carbon black, polycarboxylate and polyvinylpyrrolidone which serve as raw materials into water, mixing and stirring till the raw materials are dissolved, putting the solution into a reaction kettle, carrying out reaction under conditions of the temperature of 60 to 200 DEG C and rotating speed of 100 to 300 r / min for 5 to 24 hours, after the reaction is completed, carrying out natural cooling to obtain a pigment precursor, and carrying out washing, sintering and drying to obtain the yellow cadmium-wrapped pigment finished product. The mole ratio of the cadmium sulfate, the zirconium oxychloride, the thiourea, the urea, the white carbon black, the polycarboxylate and the polyvinylpyrrolidone is (6 to 15): (25 to 40): (5 to 35): (60 to 250): (10 to 50): (0.02 to 8.0): (0.01 to 4.0).

Owner:FOSHAN HUAYI CERAMIC COLORS CO LTD

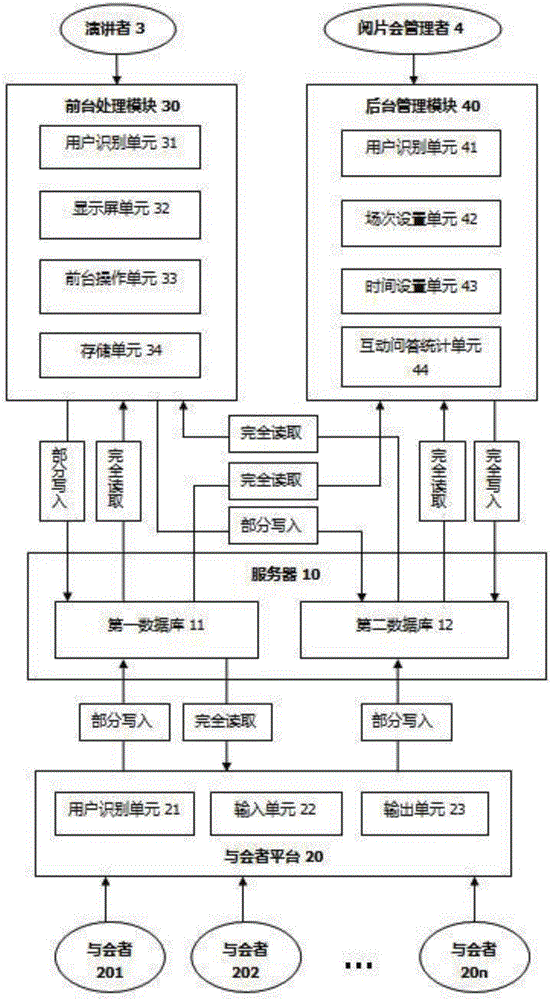

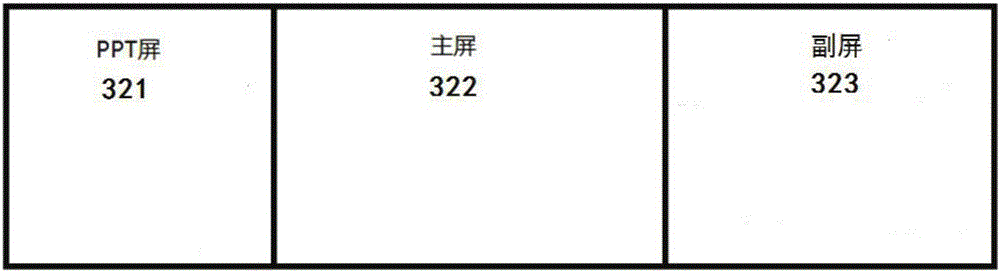

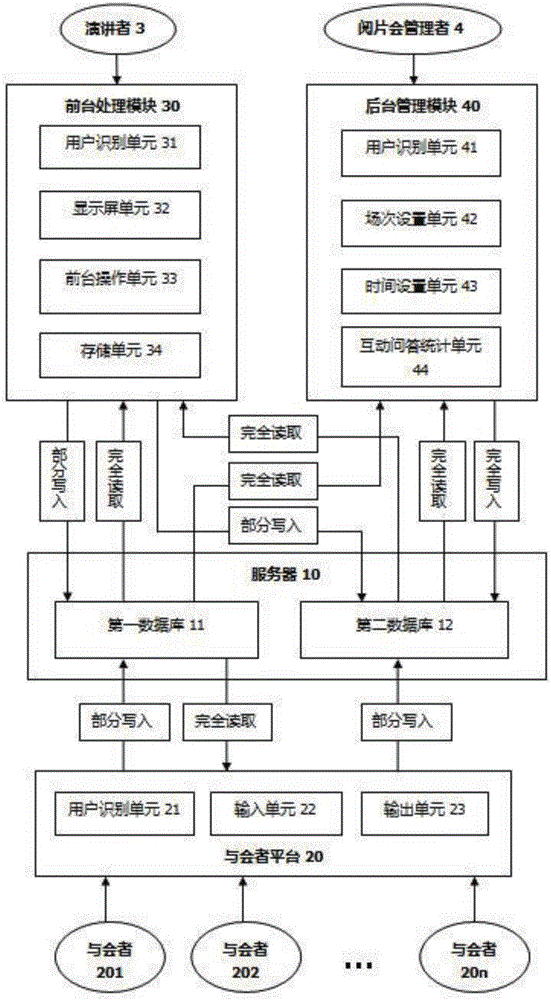

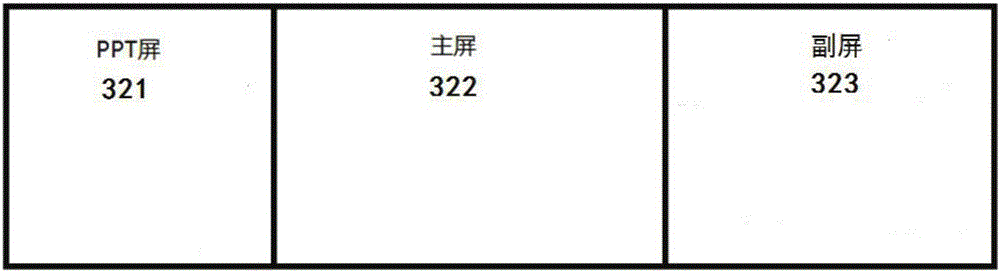

Digital film reading seminar system

ActiveCN105704165AEasy speechFacilitate communicationSpecial service provision for substationElectrical appliancesRelevant informationNetwork connection

The invention relates to a digital film reading seminar system which is characterized by comprising a server, a participant platform module, a foreground processing module and a background management module. The participant platform module, the foreground processing module and the background management module are connected with the server through the network. The server is provided with a first database which stores digital sections and related information, participant commend information and speech and presentation manuscripts and a second database which stores film reading seminar information. Multiple participants, speakers and film reading seminar managers perform transmission and exchange of the digital sections and the related information, the participant commend information and / or the film reading seminar information with the server through the participant platform module, the foreground processing module and the background management module respectively. Easy switching of the presentation manuscripts, the digital sections and interaction with the participants in the speech of the speakers can be realized, and the smoother discussion on the content of the film reading seminar can be obtained between the participants and the speakers and between the participants.

Owner:广州华银医学检验中心有限公司

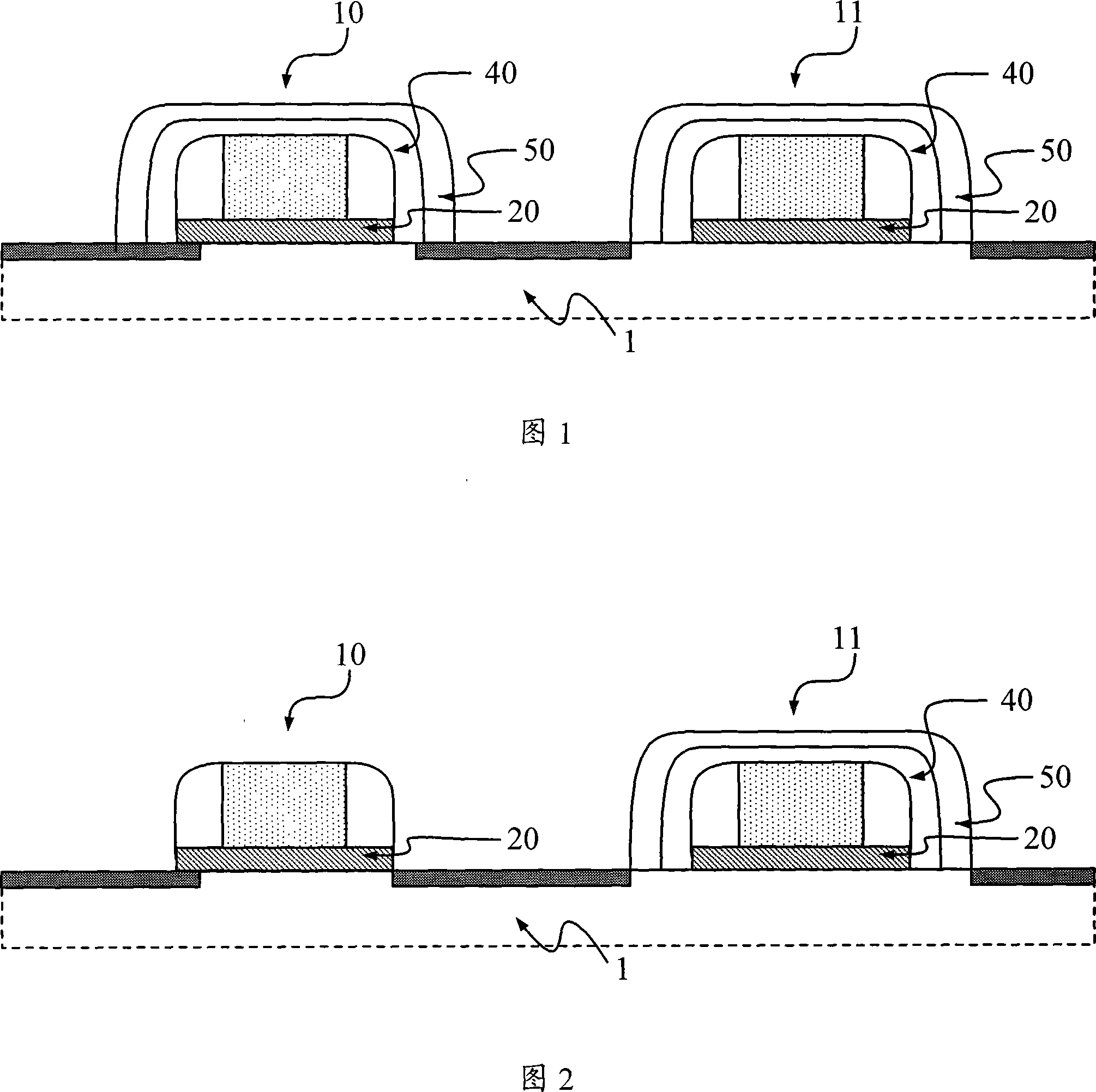

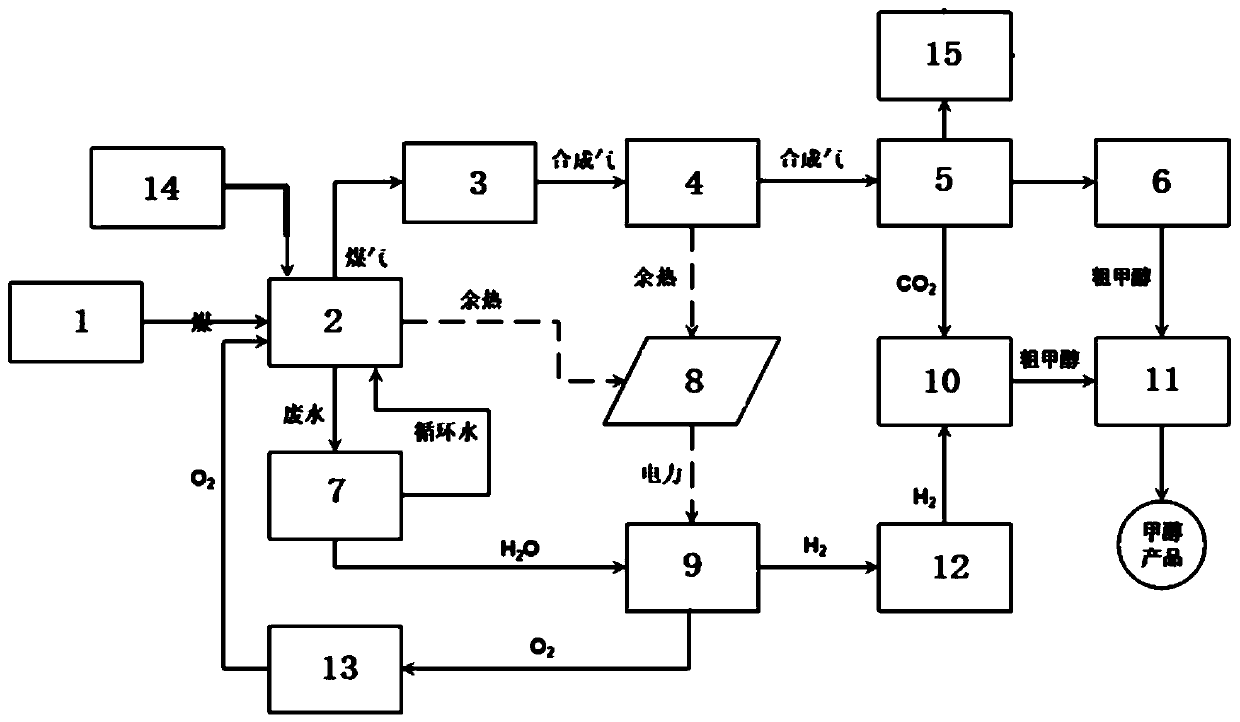

A non volatile memory structure and its making method

InactiveCN101170115ASolve problemsControl processSolid-state devicesSemiconductor/solid-state device manufacturingDielectricEngineering

The invention provides a non-volatile memory structure and a manufacture method thereof. The device includes an underlay with a surface area, which is provided thereon with a plurality of grid dielectric medium layers, wherein, at least two grid dielectric medium layers are provided thereon with a control grid and a floating grid respectively. The control grid and the floating grid are covered by a silicon dioxide barrier layer and a silicon nitride shield layer in turn. The barrier layer and the shield layer co-form a self alignment barrier layer (SAB). The invention has the advantages of good data retentivity, logic process compatibility, simpler process control and efficiency improvement.

Owner:GRACE SEMICON MFG CORP

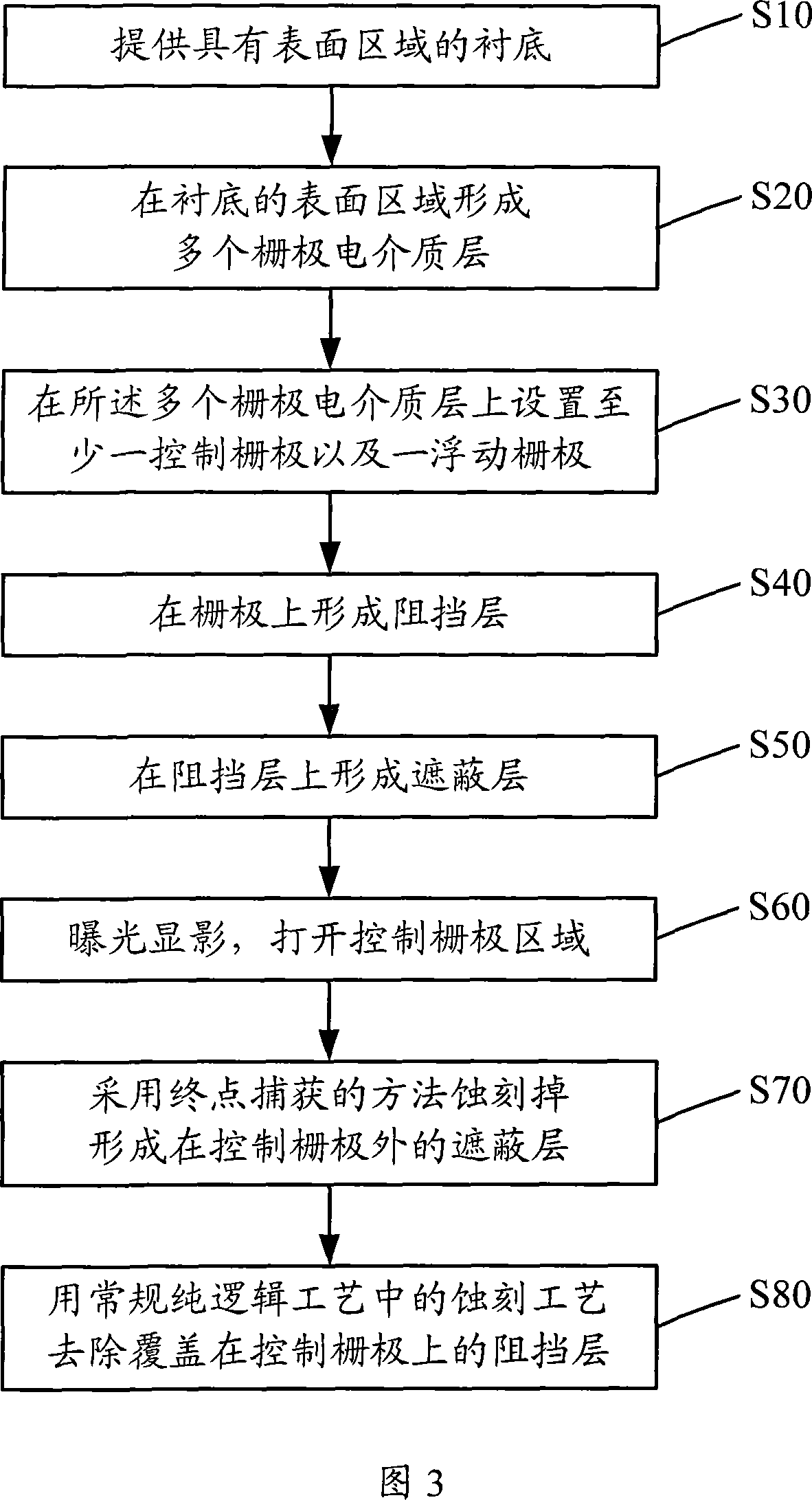

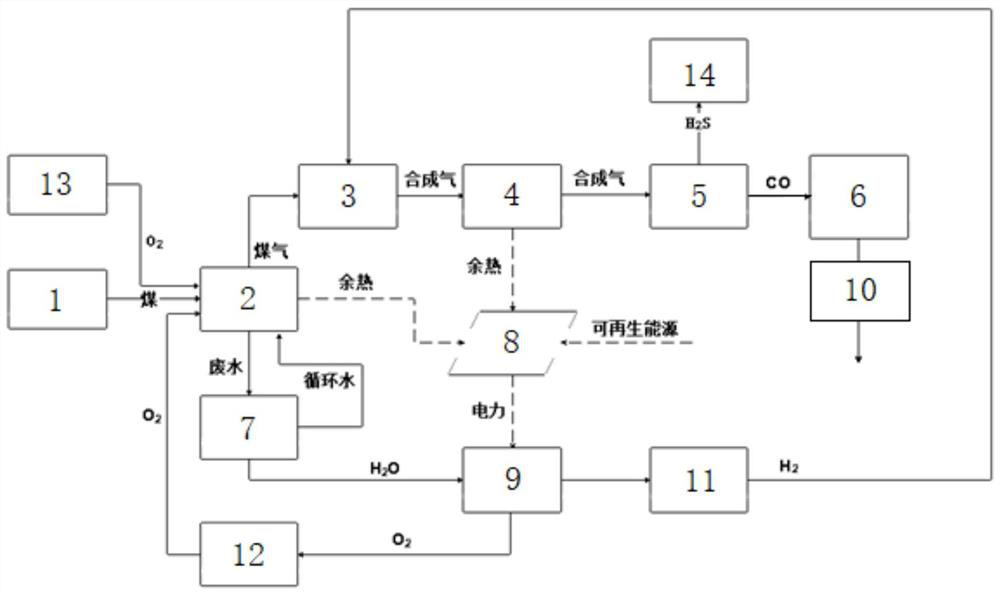

Carbon dioxide conversion system used in coal-to-methanol process and working method thereof

PendingCN111559956AIncrease productionReduce cost inputHydrogenElectrolysis componentsElectrolysisWater processing

The invention discloses a carbon dioxide conversion system used in a coal-to-methanol process and a working method thereof, belonging to the technical field of the coal chemical industry. The system comprises a coal preparation unit, a coal gasification unit, a water gas conversion unit, a synthesis gas cooling unit, a low-temperature methanol washing unit, a synthesis gas-to-methanol unit, a water treatment unit, a waste heat power generation unit, an electrolytic hydrogen production unit, a CO2-to-methanol unit, a methanol rectification unit, a hydrogen collection unit, an oxygen collectionunit, an air separation unit and a sulfur recovery unit. According to the invention, CO2 generated in the coal-to-methanol process is converted into a methanol product on site; in-situ conversion of CO2 is realized, and a conversion product is CO2; low-temperature waste heat of the coal gasification and synthesis gas cooling units is adopted for power generation, so electric energy is provided forelectrolytic hydrogen production; pure oxygen generated in the electrolytic hydrogen production process is used for the coal gasification unit; and methanol yield is high, CO2 emission is low, equipment investment and operation cost are reduced, energy in the process is effectively utilized, energy is saved, and good application prospects are achieved.

Owner:甘肃华亭煤电股份有限公司 +1

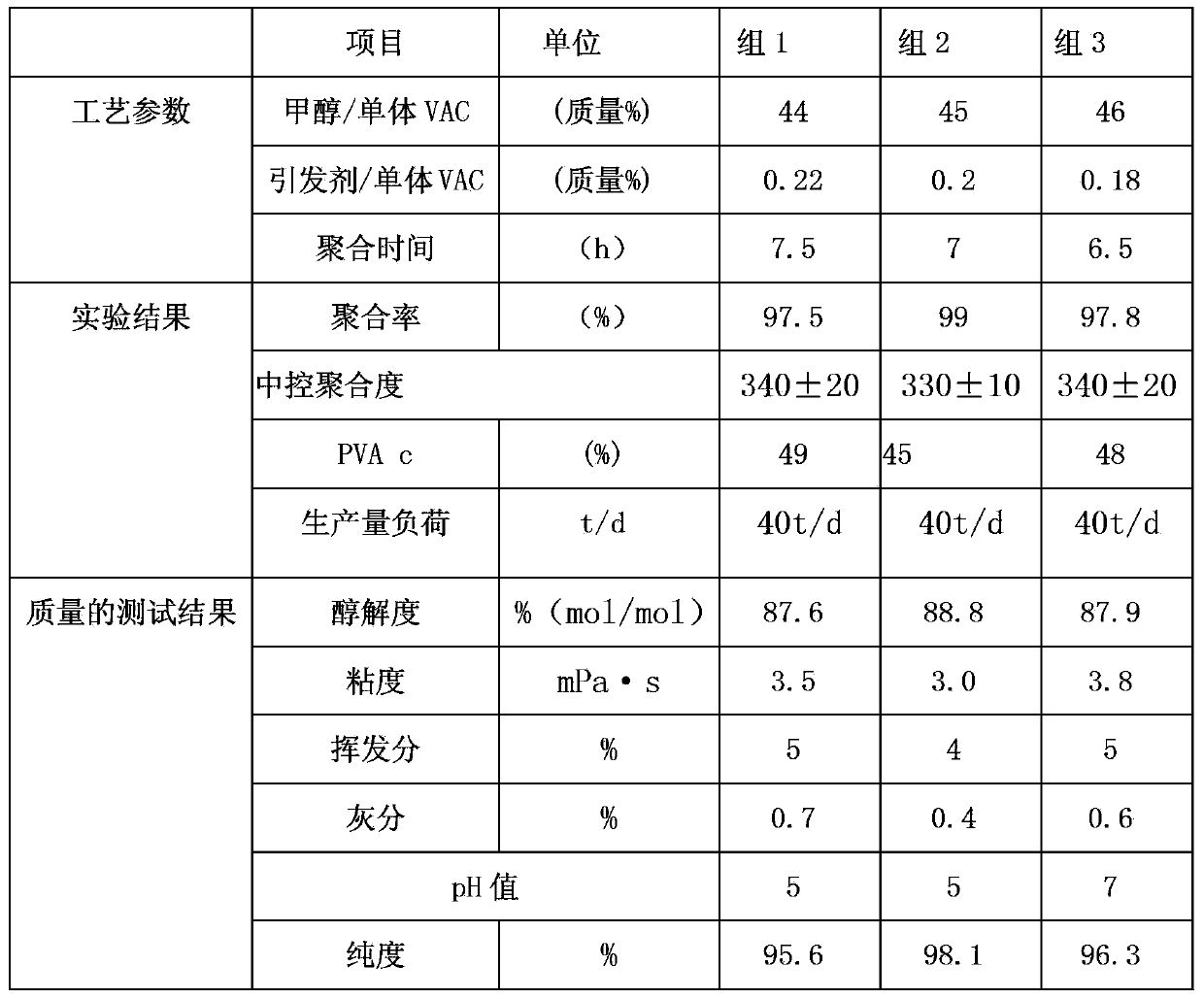

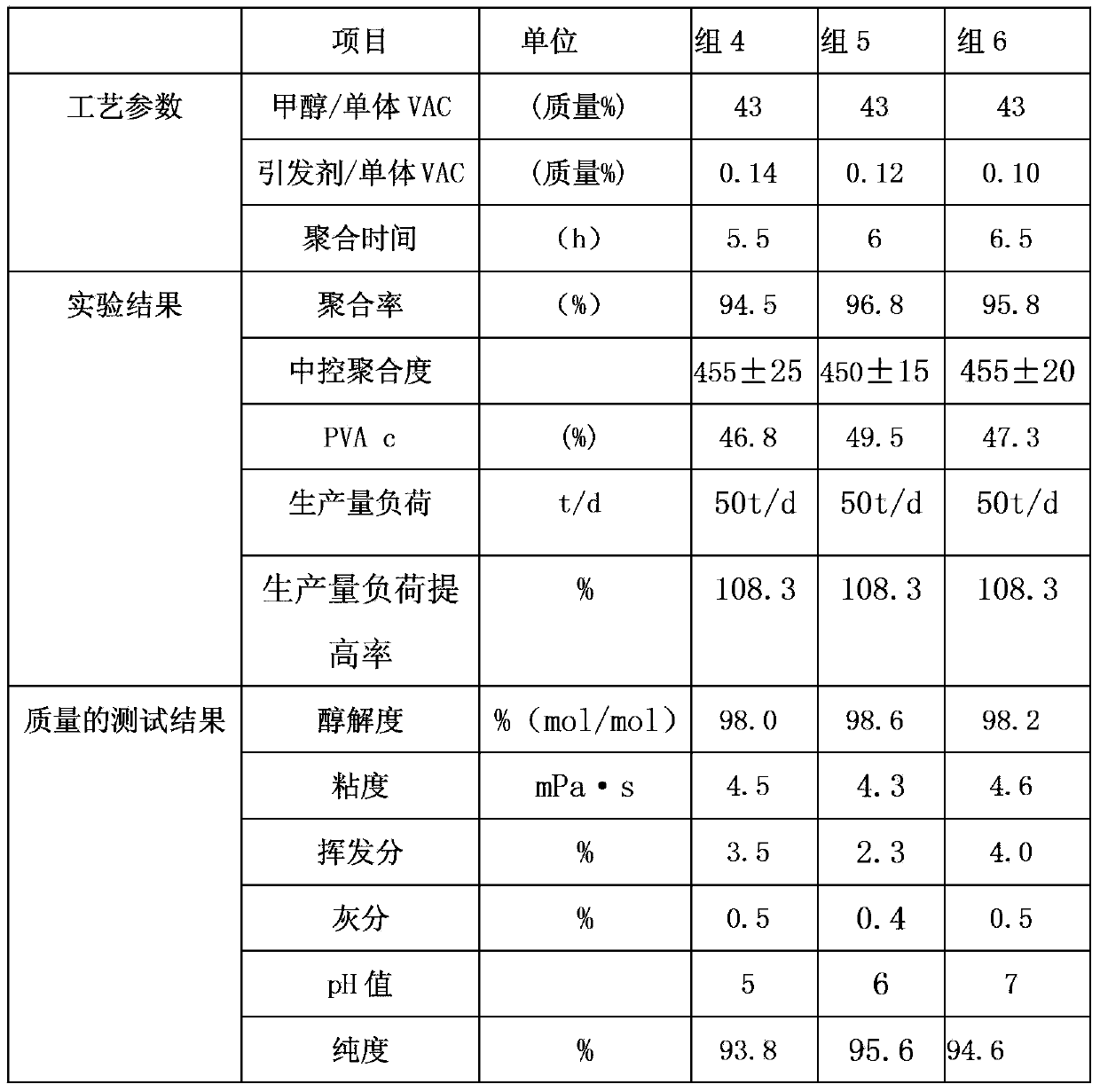

Preparation method of polyvinyl alcohol

ActiveCN104177525AReduce the amount addedReduce the degree of polymerizationPolymer scienceReaction speed

The invention provides a preparation method of polyvinyl alcohol; through control of polymerization process parameters of polyvinyl alcohol and reasonable matching of the methanol amount, the initiator amount and the reaction time, the polymerization reaction speed and course are effectively controlled, the addition amount of a catalyst is greatly reduced, resources and costs are saved, the polymerization residence time is prolonged, the reaction is more thorough and complete, and the product polymerization rate and yield are improved.

Owner:CHINA PETROCHEMICAL CORP +1

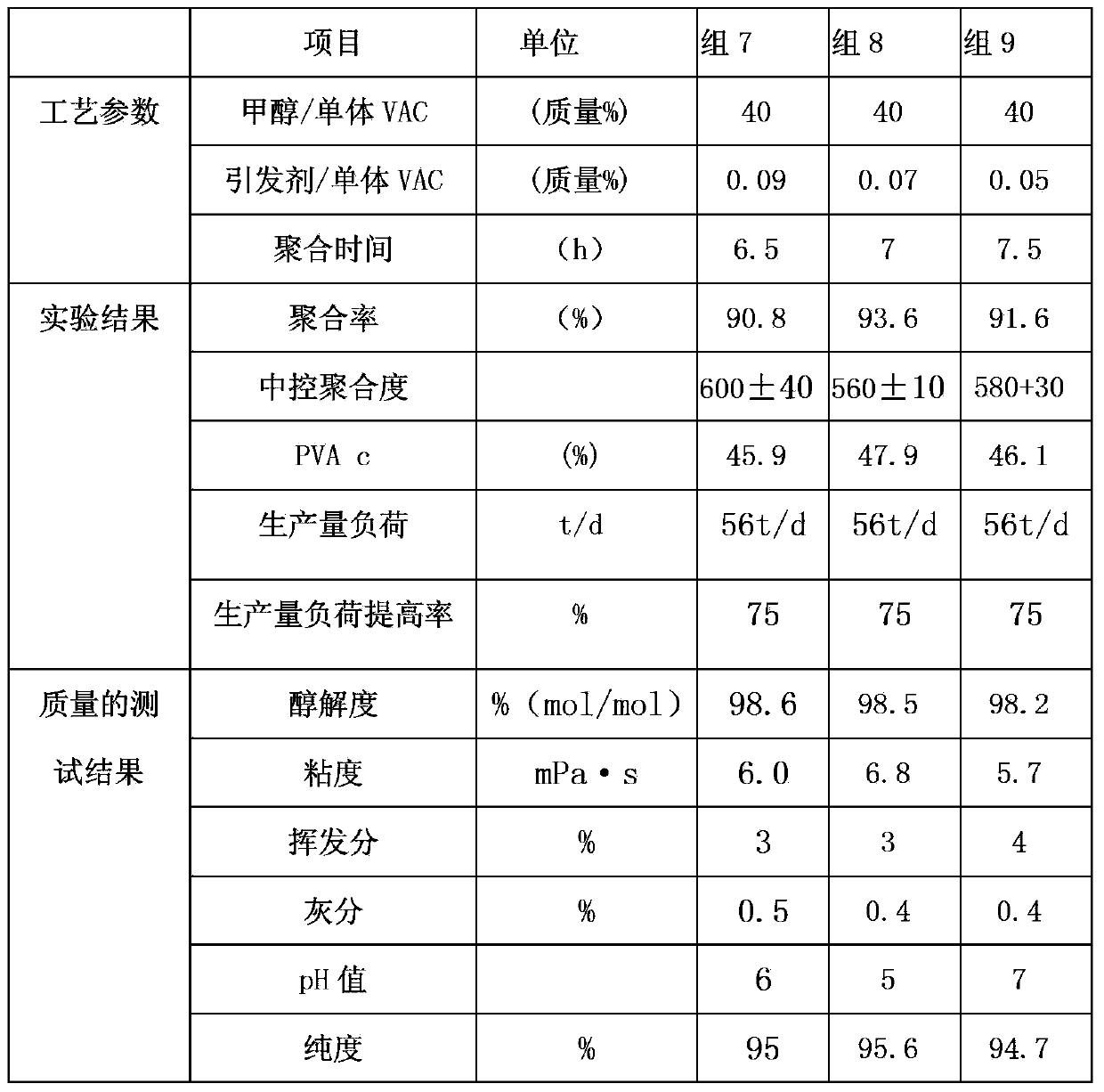

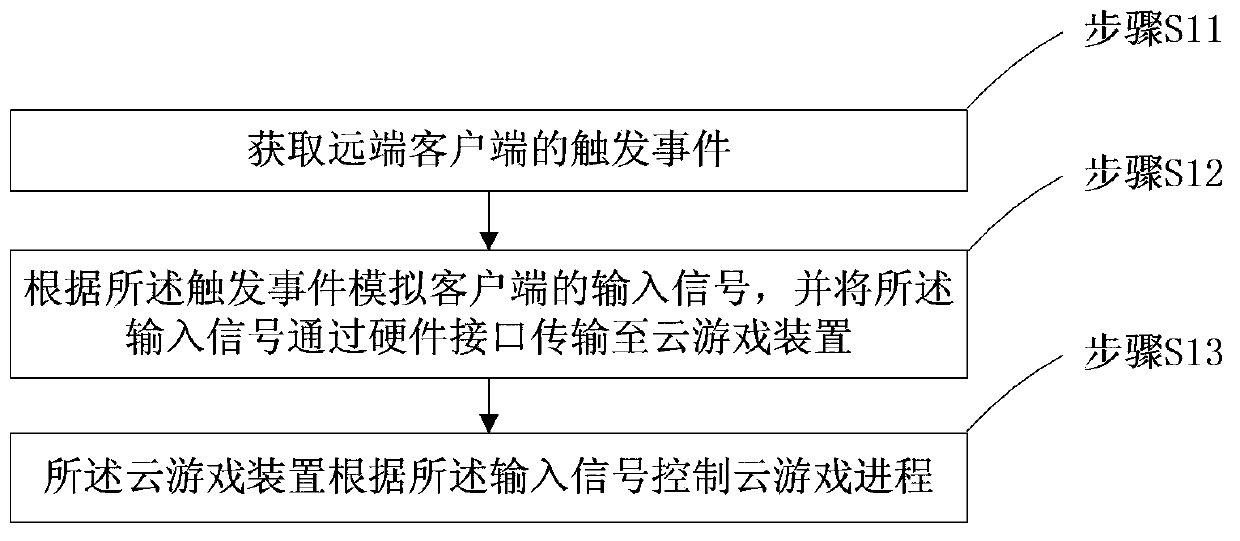

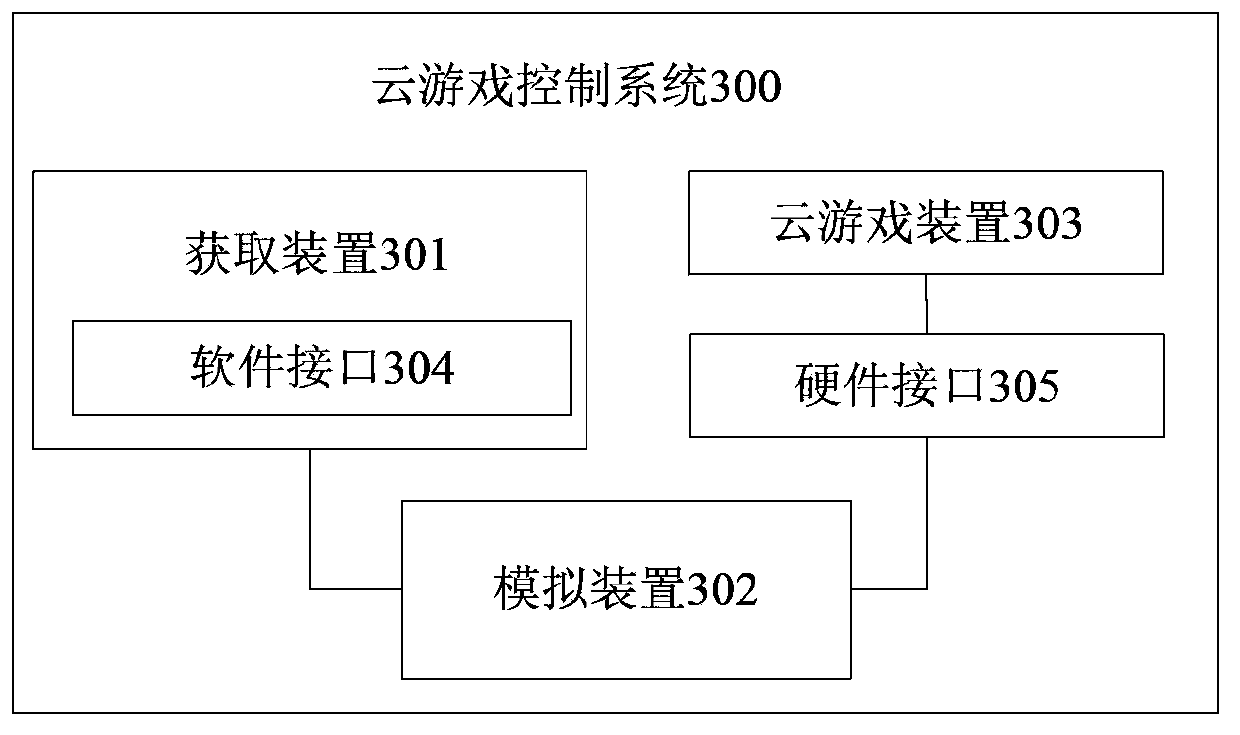

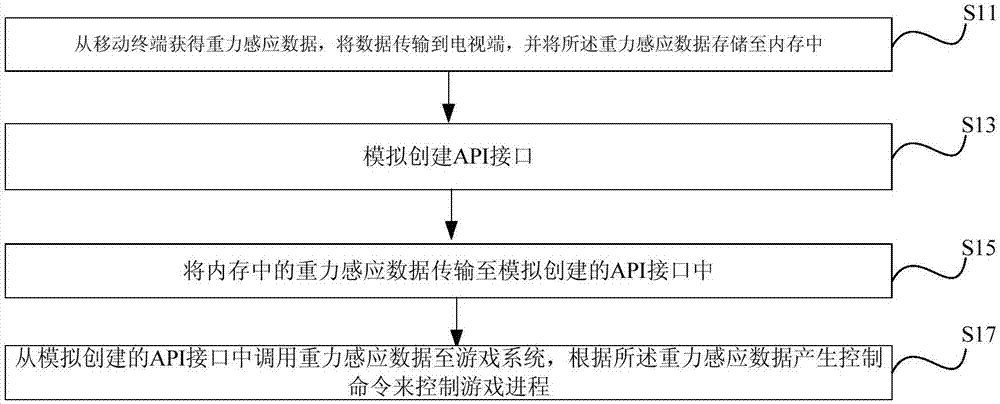

Control method and system for cloud game

InactiveCN103970279AControl processEasy to controlInput/output for user-computer interactionTransmissionOperational systemClient-side

The invention provides a control method and system for a cloud game. The control method comprises the following steps: acquiring a trigger event of a remote client; simulating an input signal of the client according to the trigger event and transmitting the input signal to a cloud game device through a hardware interface; controlling the progress of the cloud game according to the input signal by the cloud game device. According to the control method and system disclosed by the invention, a mouse signal or a keyboard signal inputted to the cloud game device through the hardware interface can be recognized by the cloud game device without being limited by the type of an operation system, and thus the progress of the cloud game is controlled and the cross-platform cloud game control is realized.

Owner:TIANJIN MIYOU TECH

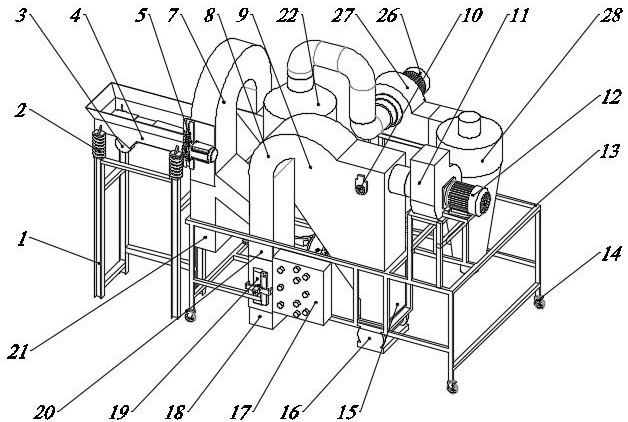

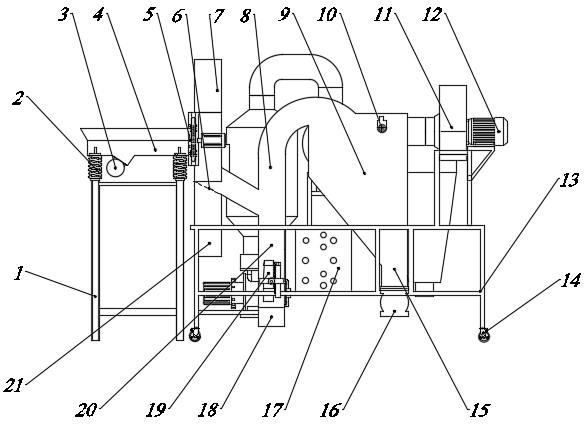

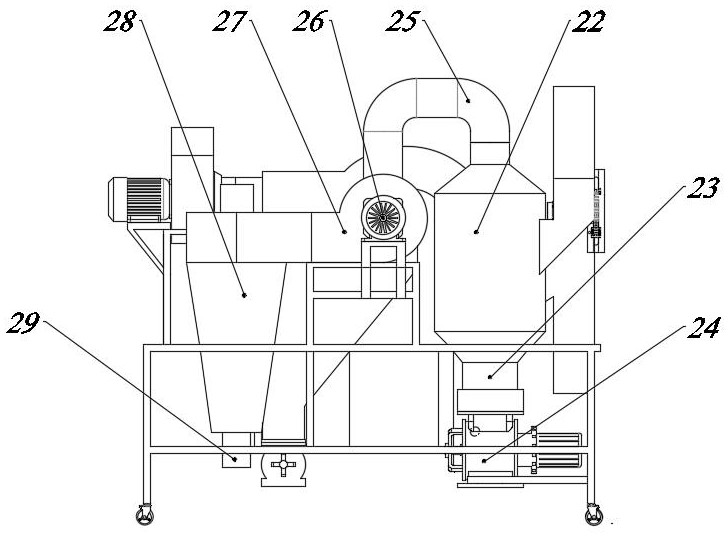

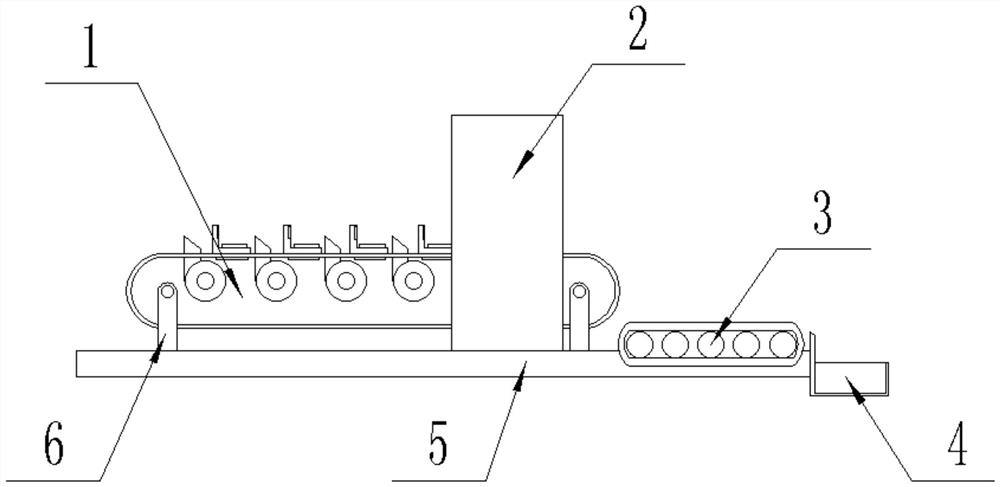

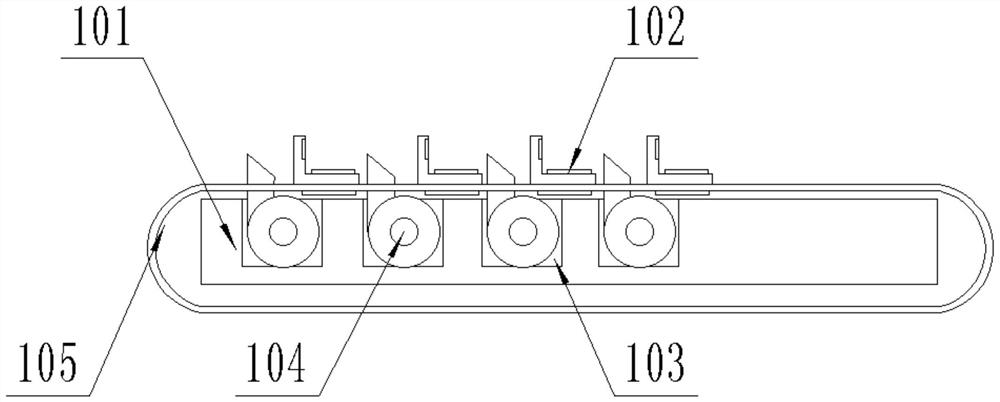

Automatic walnut shell and kernel mixture airflow sorting machine

PendingCN112845079AControl flowControl wind speedGas current separationVortex flow apparatusWalnut NutAir velocity

The invention discloses an automatic movable walnut shell and kernel mixture airflow sorting machine. The sorting machine comprises a vibratory feeding machine, an automatic material limiting and air adjusting device, a negative pressure fan, a diaphragma juglandis settling box, a cyclone dust collector, a walnut kernel discharging port automatic height adjusting device, a control cabinet and a walnut shell collecting device. The sorting machine is characterized in that a frequency converter controls the amplitude and frequency of a vibrating motor so as to control the material flow of walnut shell and kernel mixtures of different grades, the automatic material limiting and air adjusting device mounted at a feeding port controls the size and the air speed of inlets of materials of different grades, the materials flow into a shell and kernel separation cavity through an impurity removing system and a slide carriage and pass through the negative pressure fan, and walnut kernels are collected from the lower end of the discharging port, and walnut shells pass through the separation cavity and enter an unloading box to be collected. According to the sorting machine, automatic control over the material flow of the shell and kernel mixtures of different grades and the required air speed and air quantity is realized, and the sorting machine is suitable for separation and collection of the shells, the kernels and diaphragma juglandis of different grades generated after mechanical walnut shell breaking.

Owner:XINJIANG UNIVERSITY

Method for remote control of video games and television

InactiveCN107888957AControl processNo other cost inputSelective content distributionInput/output processes for data processingSensing dataRemote control

The embodiment of the invention discloses a method for remote control of video games and a television. The method for remote control of the video games comprises the following steps: obtaining gravitysensing data from a mobile terminal, and transmitting the data to the television terminal; storing the gravity sensing data into the memory by the television terminal; creating an API interface by simulation; transmitting the gravity sensing data in the memory to the API interface created by simulation; and invoking the gravity sensing data from the API interface created by simulation to the gamesystem, so as to generate control commands according to the gravity sensing data to control the game process.

Owner:STARTIMES SOFTWARE TECH CO LTD

System for simplifying coal-to-methanol production by adjusting carbon-hydrogen ratio with hydrogen and working method of system

ActiveCN113045382ASmall volumeReduce loadHydrocarbon from carbon oxidesOrganic compound preparationElectrolysisElectric power

The invention discloses a system for simplifying coal-to-methanol production by adjusting a carbon-hydrogen ratio through hydrogen and a working method of the system, belonging to the technical field of coal chemical industry. The system mainly comprises a coal preparation unit, a coal gasification unit, a carbon-hydrogen ratio adjusting unit, a synthesis gas cooling unit, a low-temperature methanol washing unit, a unit for preparing methanol or methane from synthesis gas, a water treatment unit, a power generation unit, an electrolytic hydrogen production unit, a hydrogen collection unit, an oxygen collection unit, an air separation unit and a sulfur recovery unit. According to the invention, hydrogen obtained by electrolytic hydrogen production of renewable energy is used for adjusting the carbon-hydrogen ratio of the synthesis gas of the coal gasification unit and is directly used for preparing methanol or methane from the synthesis gas, and a conversion unit is not needed, so the load of the system is reduced, and operation cost is reduced; low-temperature waste heat of the coal gasification and synthesis gas cooling units is adopted for power generation, electric energy is provided for electrolytic hydrogen production, and extra power input is not needed, so energy consumption and production cost are reduced; and pure oxygen generated in an electrolytic hydrogen production process is used for the coal gasification unit, so the load of the air separation unit of the system is reduced, and production and operation cost is reduced.

Owner:HUANENG CLEAN ENERGY RES INST +1

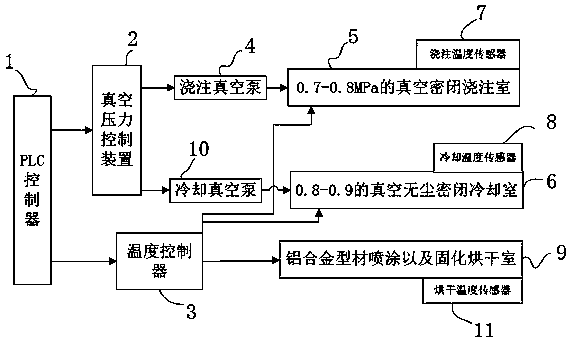

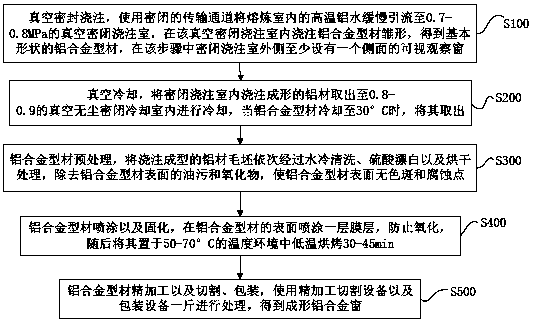

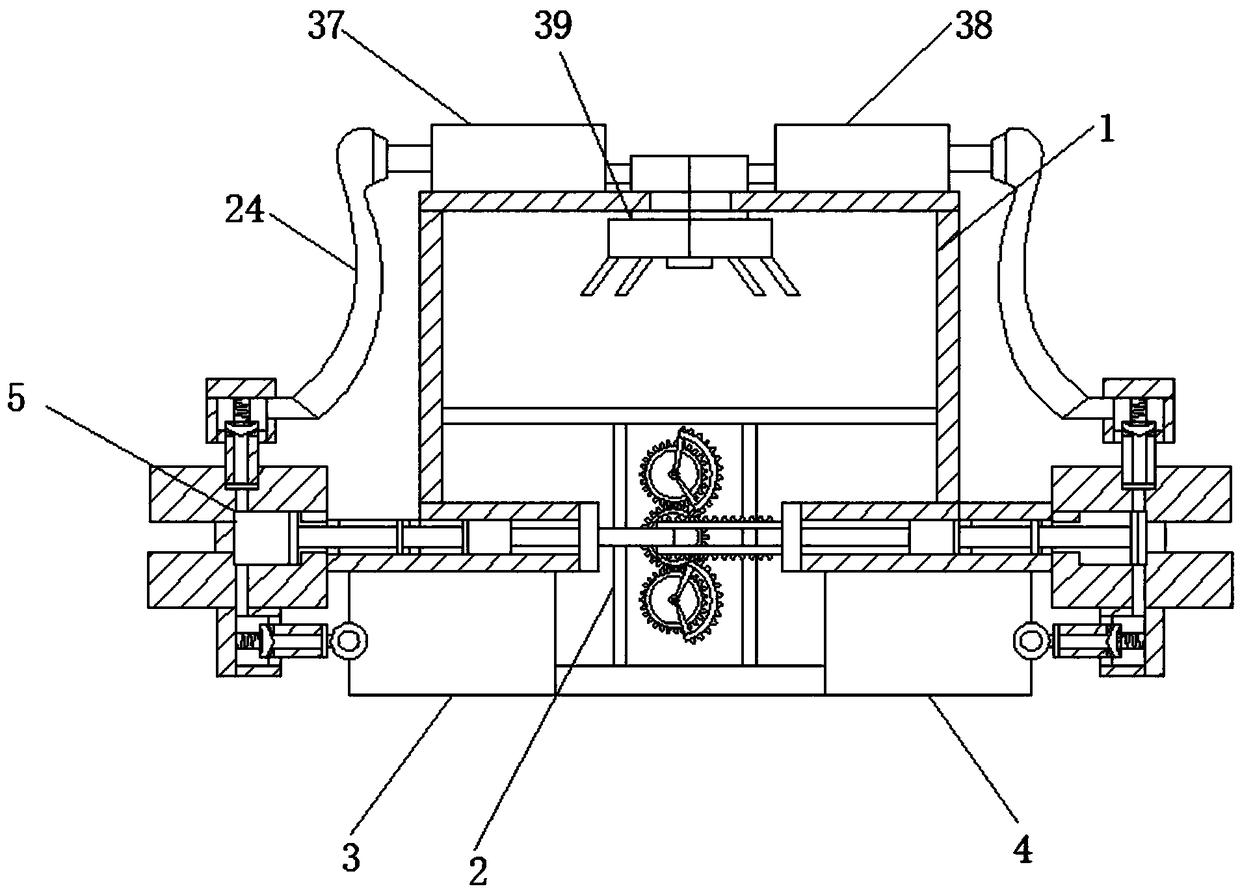

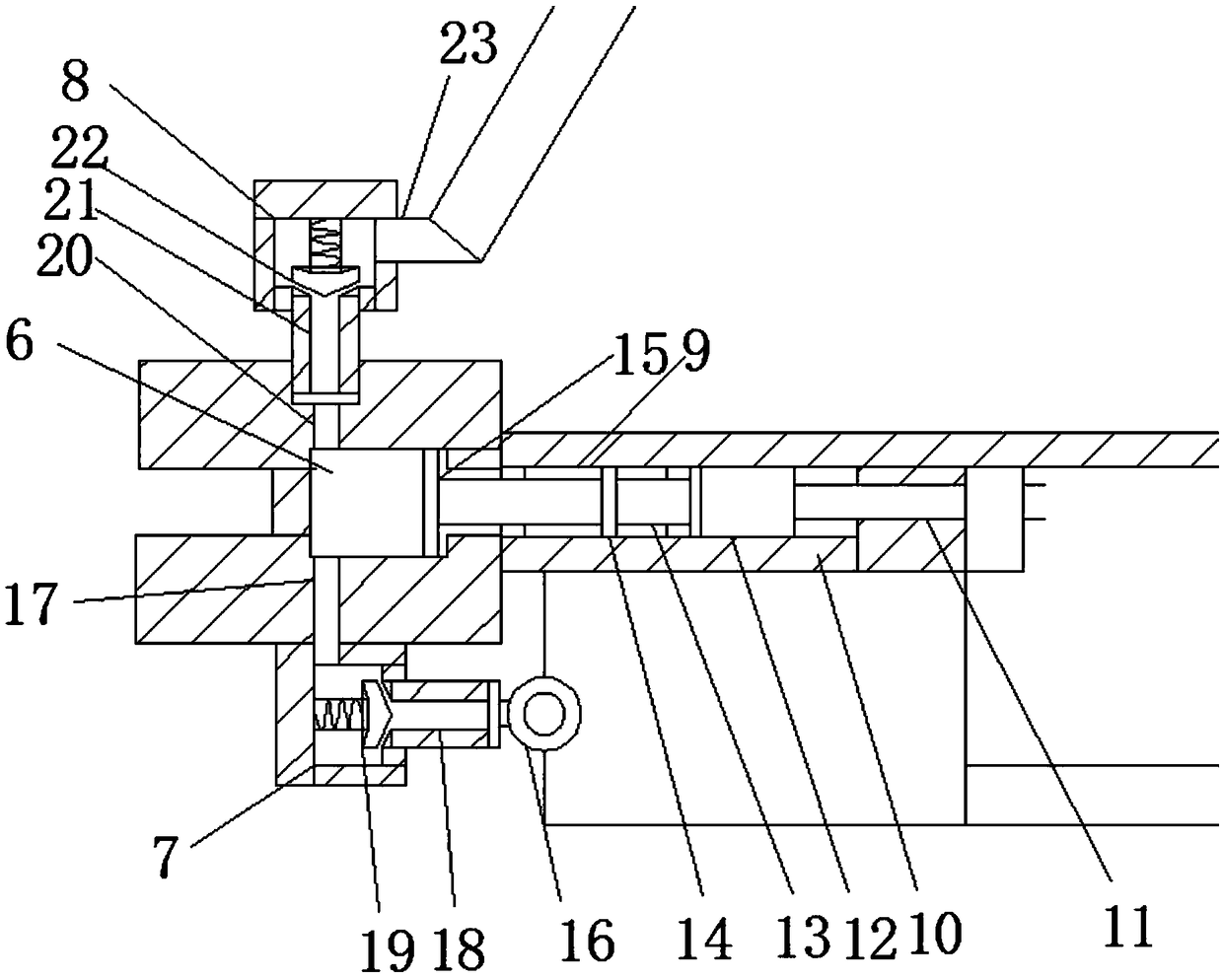

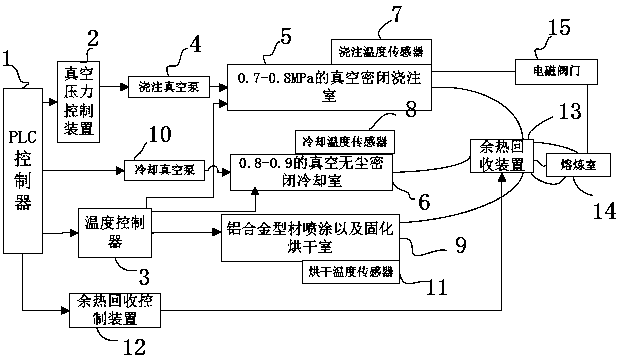

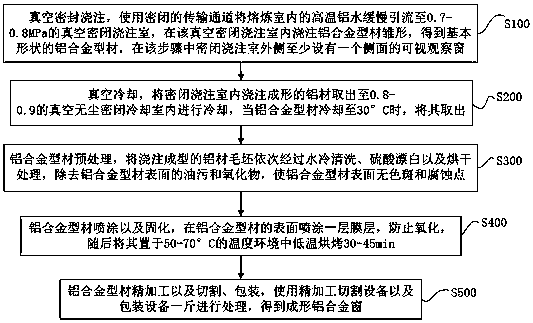

Control system and machining method of door and window aluminum profile vacuum casting

The invention discloses a control system and a machining method of door and window aluminum profile vacuum casting. The control system comprises a vacuum pressure controller and a temperature controller, wherein the vacuum pressure controller and the temperature controller are connected with the PLC, wherein the vacuum pressure controller is connected to a outdoor cooling vacuum pump which is connected with a vacuum airtight pouring chamber with 0.7 to 0.8 MPa through a pouring vacuum pump to control the cooling vacuum pump to be in an vacuum state; and is connected with a vacuum dust-free closed cooling chamber with 0.8-0.9 MPa to control the vacuum dust-free closed cooling chamber to be in the vacuum state; and a pouring temperature sensor 7 of the vacuum airtight pouring chamber with 0.7 to 0.8 MPa, a cooling temperature sensor of the vacuum dust-free closed cooling chamber with 0.8-0.9 MPa and aluminum alloy section spraying and a drying temperature sensor of a curing and drying room are connected with the temperature controller. The aluminum alloy door and window manufactured by using the vacuum pouring control system and the method machining technology are strong in weather resistance and corrosion resistance, the appearance quality is good, the system and method can be used in various climate environments, and a anti-fatigue performance is good, the system and the methodare wide in application range and long in overall service life.

Owner:ANHUI GAODE ALUMINUM

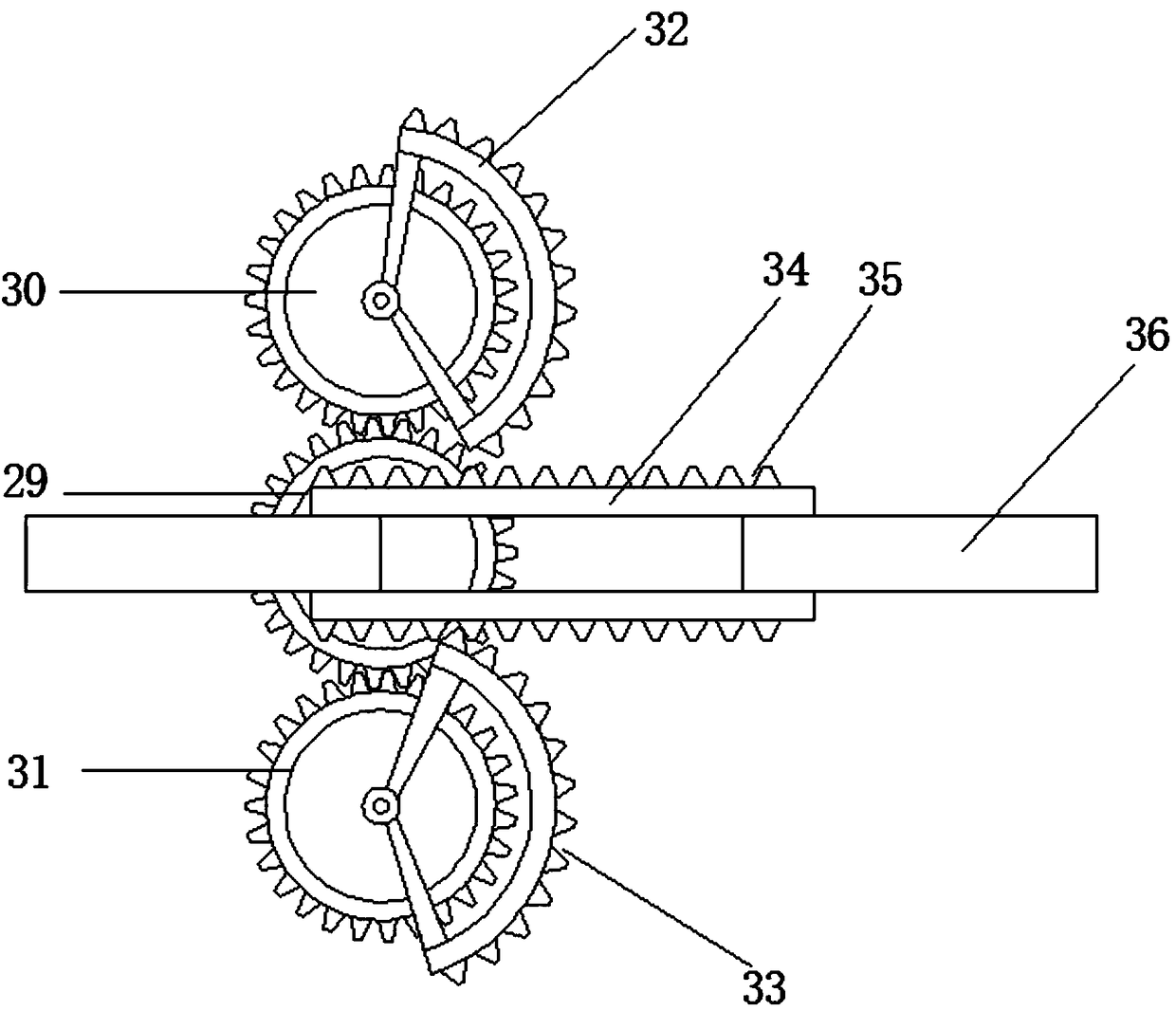

Chemical liquid reaction kettle capable of uniformly conveying materials

The invention discloses a chemical liquid reaction kettle capable of uniformly conveying materials. The chemical liquid reaction kettle comprises a reaction kettle and a transmission box, wherein theleft and right sides of the transmission box are respectively provided with a material conveying mechanism, and the bottom ends of the material conveying mechanisms at the left and right sides are respectively provided a first material conveying box and a second material conveying box; a drive motor is mounted on the rear side of the transmission box; a gearbox is mounted on the front end of the drive motor; a transmission shaft is mounted on the front end of the gearbox; the front end of the transmission shaft is provided with a transmission gear; the upper and lower ends of the transmissiongear are respectively provided with a first driven gear and a second driven gear; the first driven gear and the second driven gear are engaged with the transmission gear; the front ends of the first driven gear and the second driven gear are respectively provided with a first notched gear and a second notched gear; and a movable frame is arranged between the material conveying mechanisms located at the left and right sides the invention is adjustable The chemical liquid reaction kettle provided by the invention can adjust a feeding rate and effectively control the progress of a reaction, and is applicable to operation of high-quality chemical products.

Owner:朱园园

Aluminum profile vacuum machining control system based on waste heat recovery

The invention discloses an aluminum profile vacuum machining control system based on waste heat recovery. The aluminum profile vacuum machining control system comprises a vacuum pressure controller, atemperature controller and a waste heat recovery control device which are connected with a PLC (Programmable Logic Controller), wherein the vacuum pressure controller is connected in a vacuum closedpouring chamber with 0.7-0.8 MPa through a pouring vacuum pump so as to control the vacuum state of the vacuum closed pouring chamber, and is connected in a vacuum dust-free closed cooling chamber with 0.8-0.9 through a cooling vacuum pump so as to control the vacuum state; waste heat in the vacuum closed pouring chamber with 0.7-0.8 MPa and waste heat in the vacuum dust-free closed cooling chamber with 0.8-0.9 are introduced to a smelting chamber through a waste heat recovery device and the waste heat recovery control device; and the waste heat recovery control device is used for recording the hot air conveying amount in the waste heat recovery device and the hot air temperature in a certain time interval. An aluminum alloy door and window manufactured by the aluminum profile vacuum machining control system based on waste heat recovery are high in weather resistance and corrosion resistance, good in appearance quality, capable of carrying out waste heat recovery and monitoring in realtime and good in environment-friendly performance.

Owner:ANHUI GAODE ALUMINUM

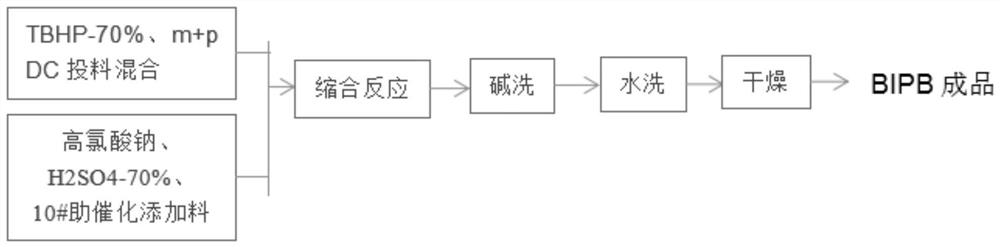

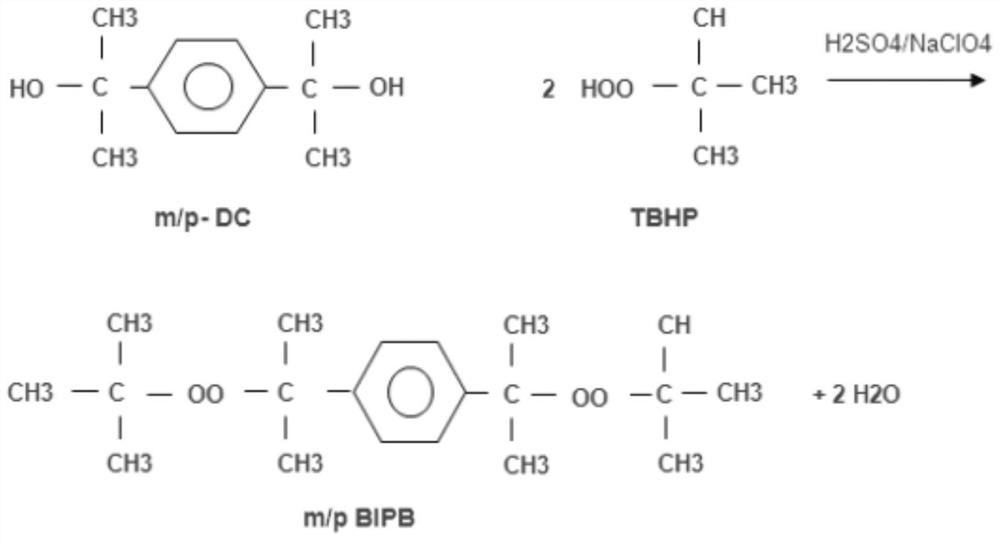

Condensation reaction method for synthesizing meta-position and para-position 2-(tert-butylperoxyisopropyl)benzene

PendingCN113999151AReduce usageEmission reductionOrganic compound preparationPeroxy compound preparationInorganic saltsSewage treatment

The invention discloses a condensation reaction method for synthesizing meta-position and para-position 2-(tert-butylperoxyisopropyl)benzene. The synthesis reaction process comprises the following step: step S1, metering and adding the raw material TBHP (tert-butyl hydroperoxide) with a concentration of 70% into a condensation reaction kettle according to a charging ratio of 2-cumenol m+pDC to TBHP of 1: (2.3-2.8) (mol ratio), and carrying out full stirring. The invention provides the synthesis method for preparing meta-position and para-position 2-(tert-butylperoxyisopropyl)benzene (m+pBIPB for short) through condensation reaction of meta-position and para-position di-(2-hydroxy-2-propyl)benzene (m+pDC for short) and tert-butyl hydroperoxide (TBHP for short), so the use amount of the sulfuric acid with the concentration of 70% can be remarkably reduced, the treatment amount of high-concentration waste acid and sewage can be reduced, sodium hydroxide alkali liquor required for treating waste acid and inorganic salt during wastewater treatment can be reduced, and a novel formula and a novel process for safe production can be ensured.

Owner:广西东岚新材料有限公司

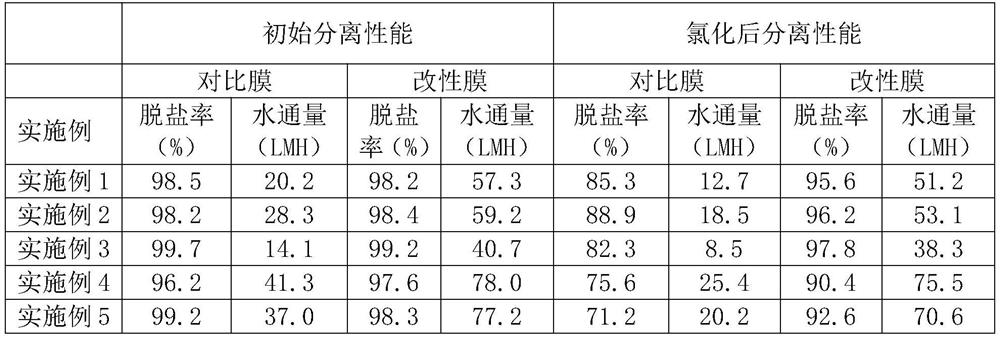

Polyamide composite membrane chlorine-resistant high-flux modification method based on ketone free radicals

InactiveCN114307684AReduce chemical reactivityImprove chlorine resistanceSemi-permeable membranesGeneral water supply conservationPolyamideKetone

The invention belongs to the technical field of organic membrane materials, and particularly relates to a polyamide composite membrane chlorine-resistant high-flux modification method based on ketone free radicals. According to the polyamide composite membrane, a polyamide active layer is modified in a free radical grafting mode, free radicals are generated by mixing a substrate and an oxidizing agent, the free radicals are ketone free radicals, the substrate is small molecule ketone with the carbon number smaller than or equal to 5, and the oxidizing agent is persulfate. According to the method, ketone free radicals are introduced to amido bonds of polyamide for the first time, due to the fact that the ketone free radicals can effectively occupy reaction active sites of chlorine and polyamide and improve the hydrophilicity of polyamide, the chlorine resistance and permeability of the membrane are improved, and in addition, the modification method is simple and easy to implement, production is easy to expand, and the method has great market prospects.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

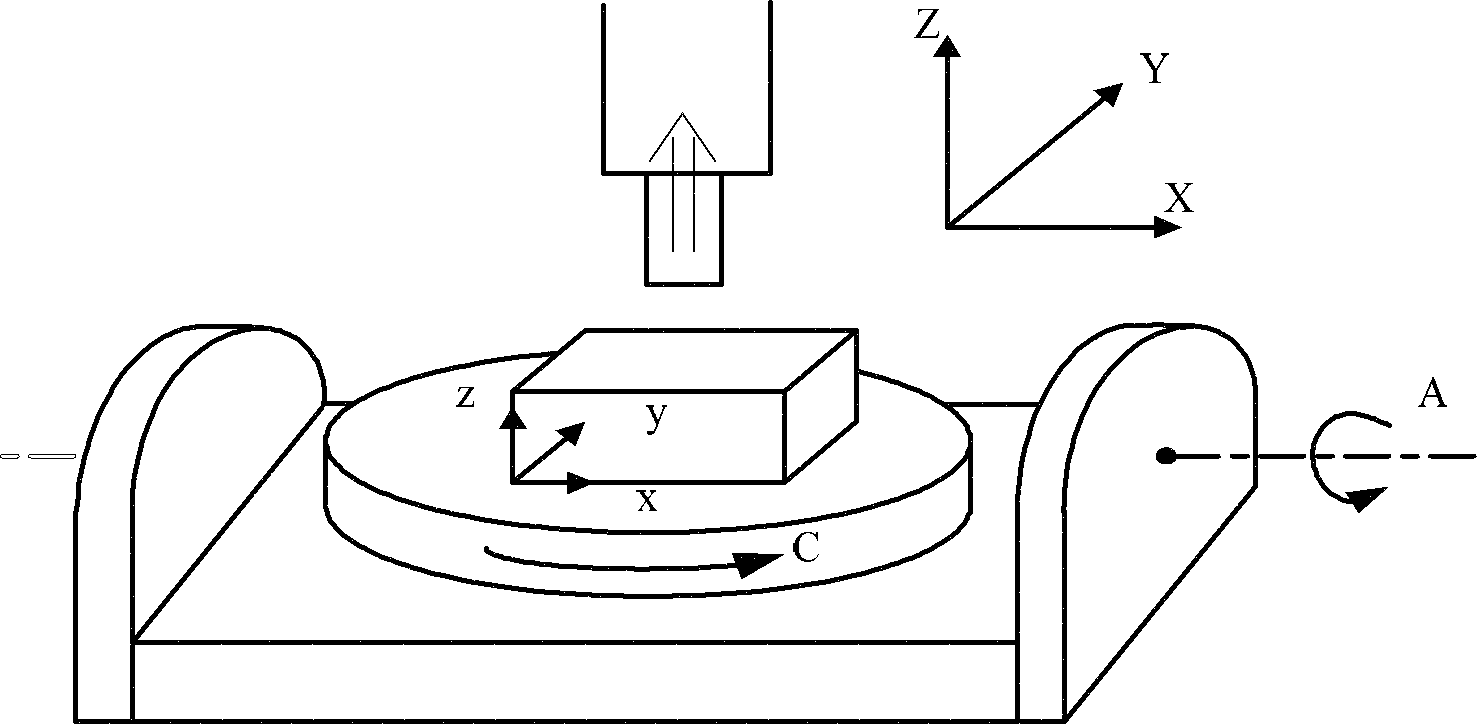

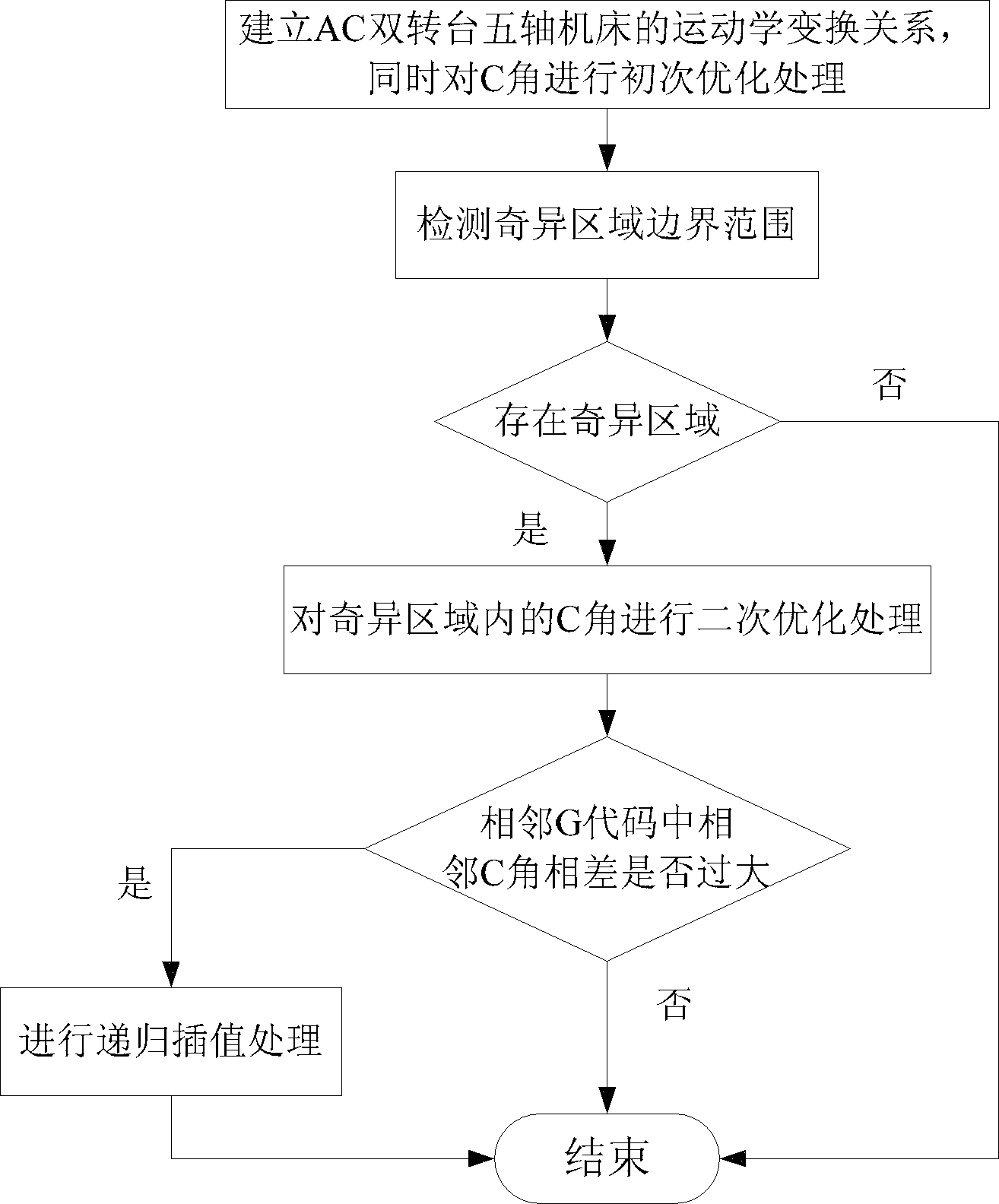

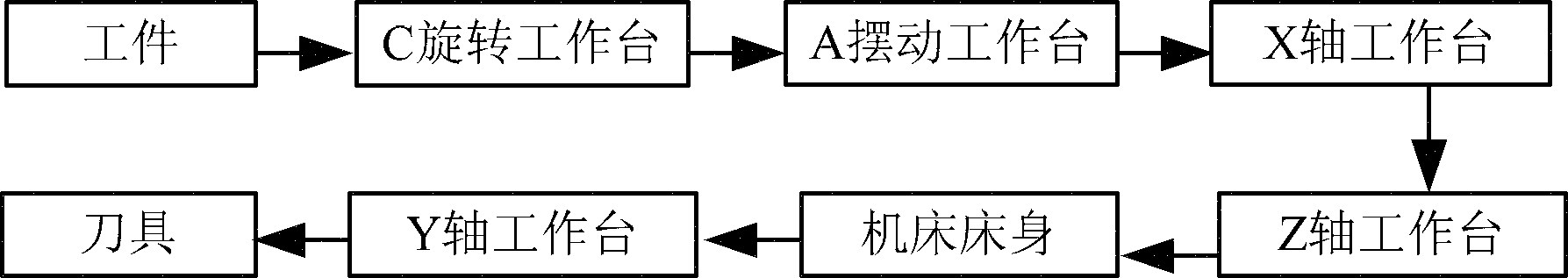

Trajectory optimization method of singular region by virtue of five-axis machining

ActiveCN102528554BReduce speed mutationReduce excessive non-linear errorsAutomatic control devicesFeeding apparatusEngineeringAlternating current

The invention relates to a processing method of a singular region by virtue of five-axis machining. The method comprises the following steps: establishing a kinematics conversion relationship of an AC (alternating current) dual-rotary-table five-axis machine tool, carrying out primary optimization treatment on a C-axle rotation angle while inverse kinematics changes so as to obtain cutter shaft data, and traversing the cutter shaft data; in the traversing process of the cutter shaft data, detecting the boundary range of the singular region by using a method based on a Jacobian matrix condition number; carrying out secondary optimization treatment on a singular point and a C angle nearby the singular point within the boundary range of the singular region to obtain new cutter shaft data; and carrying out recursion interpolation treatment on a subinterval with still larger C angle change between the two adjacent lines in the new cutter shaft data to obtain the final cutter shaft data. By adopting the method provided by the invention, velocity jump of a rotation shaft in the singular region can be effectively reduced, overlarge non-linear errors generated by the velocity jump can be reduced, the processing precision can be improved, and the machine tool as well as parts and components can be effectively protected.

Owner:中国科学院沈阳计算技术研究所有限公司

A kind of preparation method of flake silver powder

ActiveCN108555312BCentralized distributionFlat surfaceTransportation and packagingMetal-working apparatusMetallurgyFiltration

Owner:湖南省国银新材料有限公司

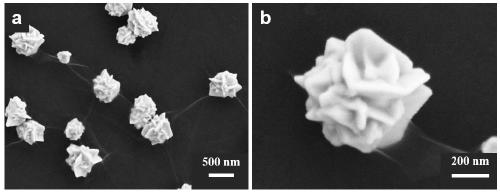

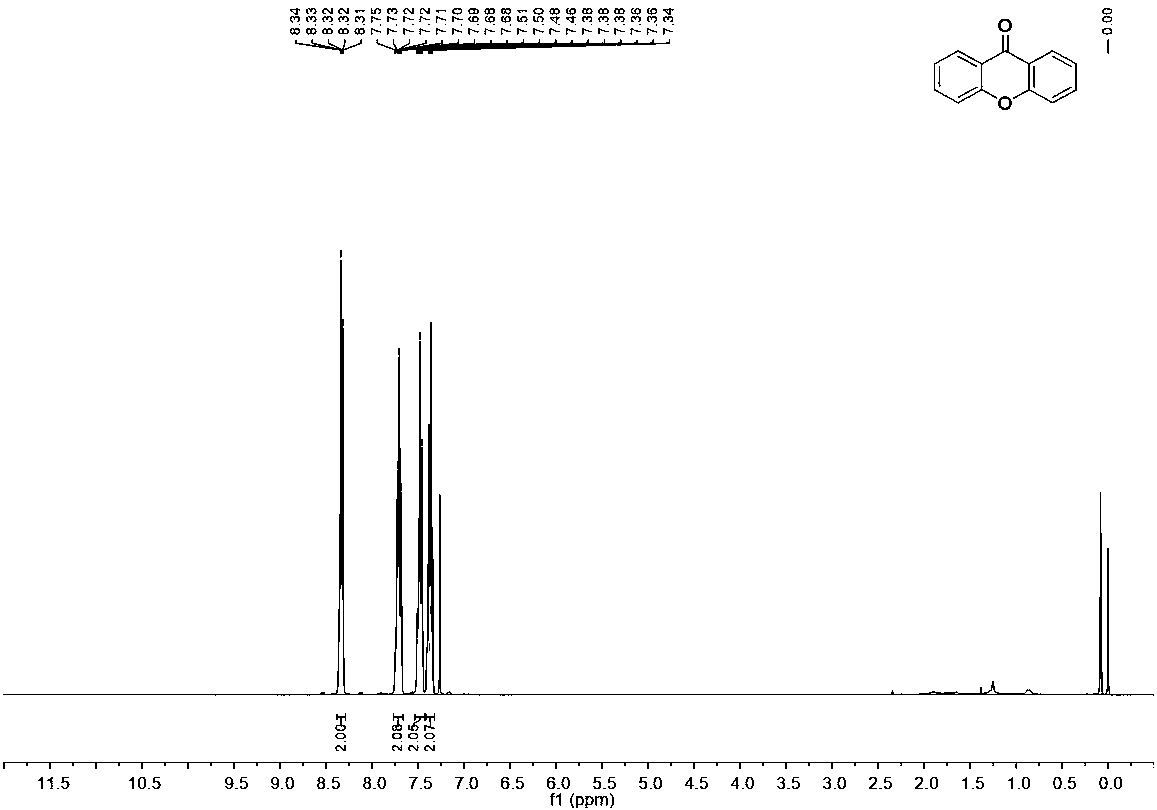

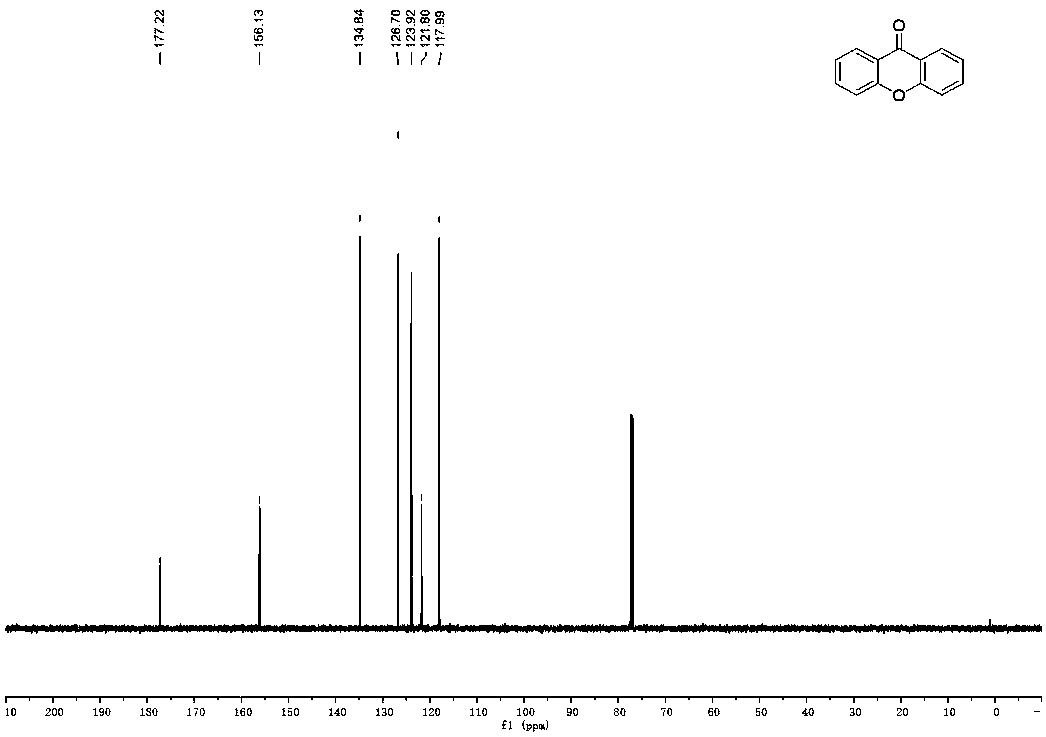

A method for preparing flower-shaped aupt alloy nanoparticles in a deep eutectic solvent and its application in electrooxidative synthesis of xanthones

InactiveCN109082685BMaintain propertiesLow viscosityTransportation and packagingMetal-working apparatusMetallurgyOrganic synthesis

The invention discloses a method for preparing flower-like AuPt alloy nanoparticles in a deep eutectic solvent with simple synthesis process, green reaction system and mild reaction conditions, and electrooxidative synthesis using the prepared flower-like AuPt alloy nanoparticles to modify electrodes. A new method of xanthone, this new electro-organic synthesis method is carried out at room temperature and in an open environment, the reaction conditions are very mild and environmentally friendly, and the yield of synthetic xanthone is high.

Owner:HENAN NORMAL UNIV

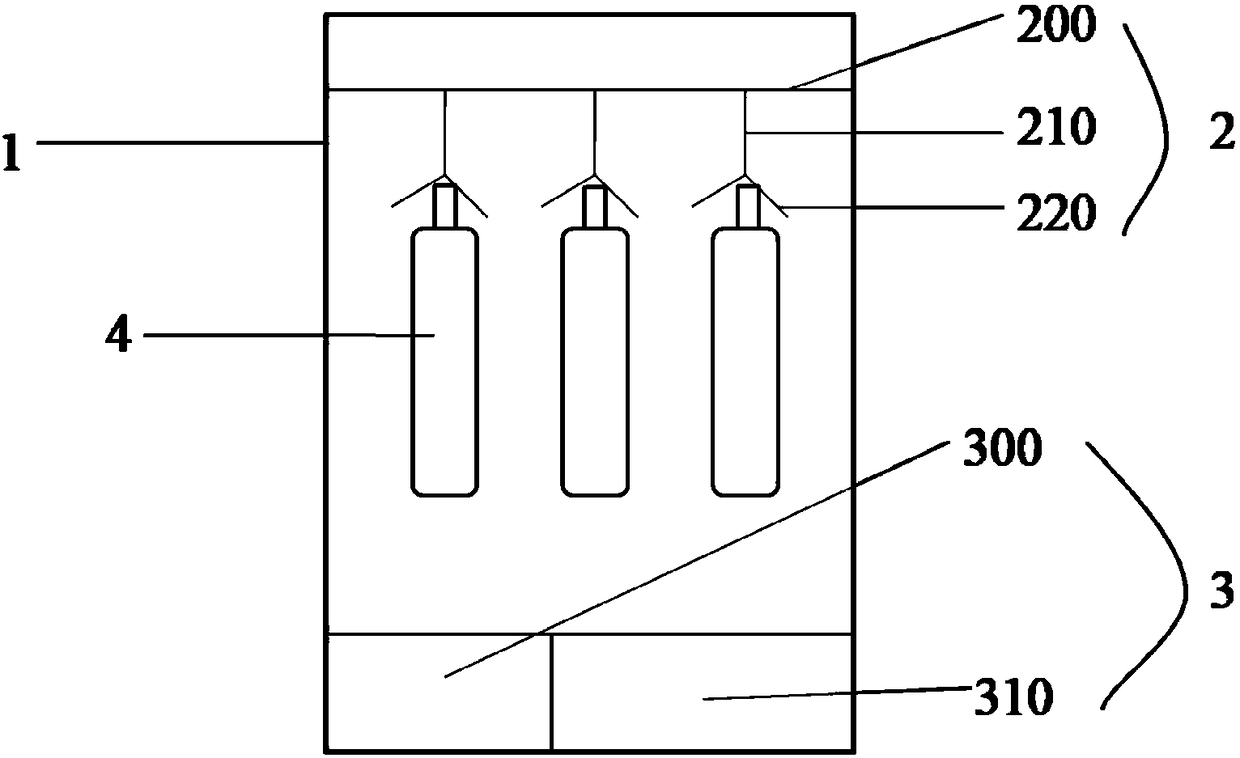

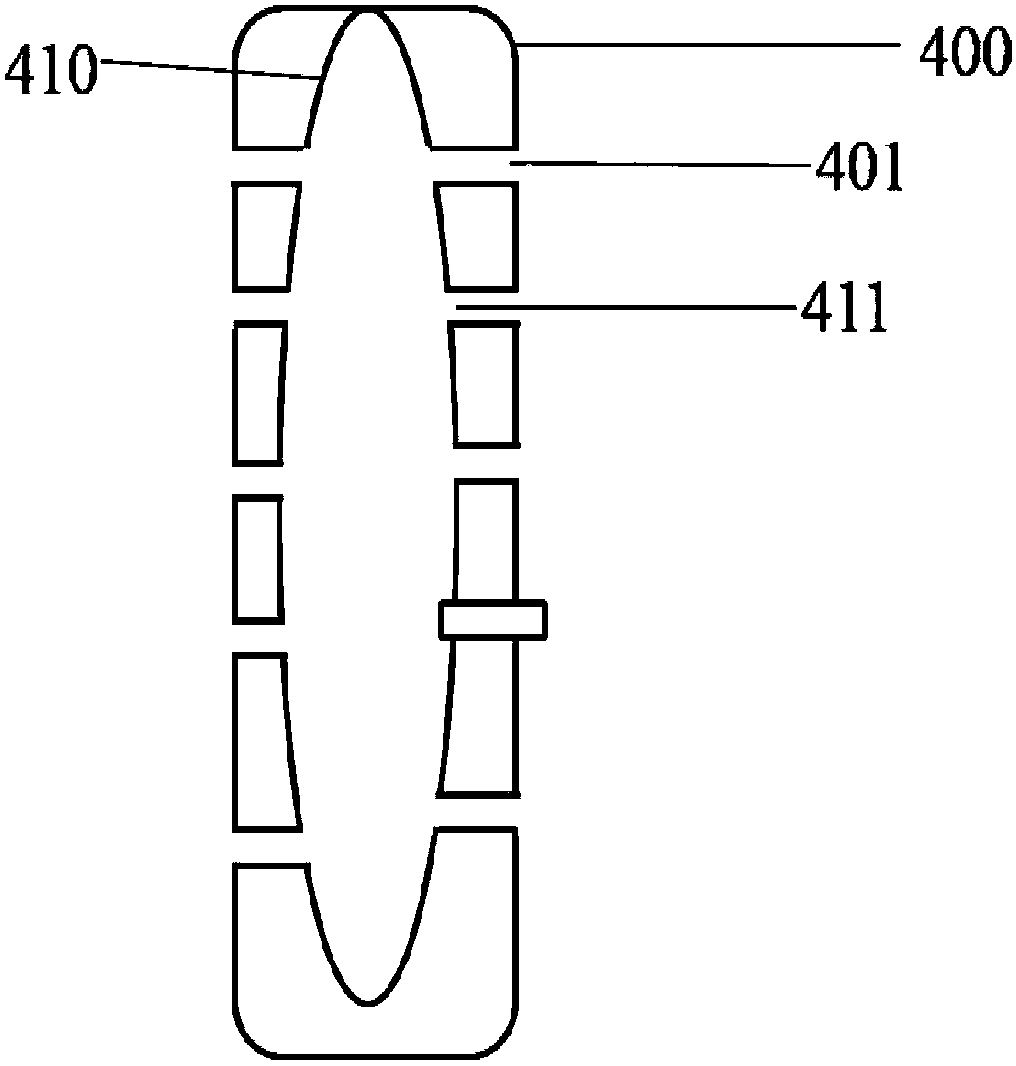

Clothes treatment device

ActiveCN106049012BProcessing speedControl processIroning apparatusOther drying apparatusBiochemical engineeringMoisture supply

The present invention provides a clothes processing device. The clothes processing device comprises a main body, a clothes support frame, a clothes processing device body, a transmission pipeline and multiple output pieces. The main body is provided with an accommodating cavity for accommodating to-be-processed clothes; the clothes support frame is arranged on the upper part of the accommodating cavity; the clothes processing device body is arranged on lower part of the accommodating cavity and comprises an air supplying unit and a moisture supplying unit; the transmission pipeline comprises a main pipeline and multiple sub-pipelines; one end of the main pipeline is connected to an output end of the air supplying unit and an output end of the moisture supplying unit; the sub-pipelines are connected to the other end of the main pipeline; the output ends of the sub-pipelines are arranged on multiple connecting rods; each of the output pieces is connected to the output end of the corresponding sub-pipeline; and the output pieces are arranged on the middle part of the clothes support frame and are arranged along the length direction of the to-be-processed clothes. According to the invention, when the clothes are in the natural vertical state, the clothes processing is rapidly finished.

Owner:黄秀开

A Digital Reading Conference System

ActiveCN105704165BFacilitate communicationEasy to switchSpecial service provision for substationElectrical appliancesRelevant informationLibrary science

Owner:广州华银医学检验中心有限公司

Forging process of lower bracket connection fork

InactiveCN103143668AReduce the risk of oxidationPrevent decarbonizationRailway componentsVehicle componentsEngineeringRound bar

The invention relates to a forging and machining process of a lower bracket connection fork of a vehicle power assembly and aims at providing a forging process of the lower bracket connection fork. The process is used for remarkably improving the machining efficiency and the product performances. The forging process of the lower bracket connection fork is characterized by comprising the following steps of: heating up round bar steel to 1050 DEG C to 1100 DEG C by an electric heating furnace; and forging the round bar steel into a finished product within 45 seconds. Preferably, the round bar steel is heated up to 1085 DEG C to 1093 DEG C by the electric heating furnace. According to the forging process of the lower bracket connection fork disclosed by the invention, simple process improvement is adopted, existing equipment is utilized, and process indexes are adjusted in a varying manner and precisely controlled, so that the product machining period is shortened, and the product machining efficiency and the product performances are improved.

Owner:CHONGQING DEKA COMPONENTS MFR OF AUTOMOBILE

Camera assembly for mobile phone

PendingCN108924400AIncrease intervalControlling the flipping processTelevision system detailsColor television detailsEngineeringMechanical engineering

The invention relates to a mobile phone shooting accessory, in particular to a camera assembly for a mobile phone. The camera assembly comprises a rack, a book pressing mechanism, an extension assembly and a shooting mechanism; the book pressing mechanism and the shooting mechanism are installed on the rack; the book pressing mechanism comprises a clamping base, an upper pressing plate, a lower pressing plate and an electric pushing rod, the clamping base clamps the spine of a book, a push rod of the electric push rod is connected with the upper pressing plate and drives the upper pressing plate to slide in the horizontal direction, the lower pressing plate is arranged under the upper pressing plate, and a jacking part is arranged on the lower end face of the lower pressing plate; and theextension assembly comprises an extension winding drum, a recycling winding drum and an elastic layer, the elastic layer is arranged under the upper pressing plate and attached to the upper pressing plate, one end of the elastic layer is wound on the extension winding drum 21, and the other end of the elastic layer is wound on the recycling winding drum. The camera assembly for the mobile phone can separate pages of the book one by one for complete scanning.

Owner:贵州维讯光电科技有限公司

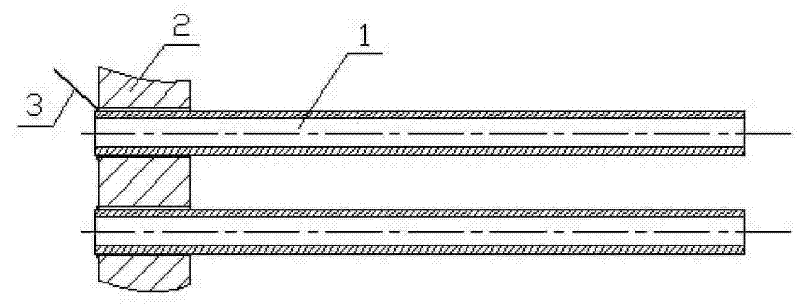

Sealing welding technique of low-alloy steel pipe plate and stainless steel pipe of low-pressure heat exchanger

InactiveCN101670478BLight in massEnhanced inhibitory effectArc welding apparatusWelding/cutting media/materialsWeld seamMetallic Nickel

The invention discloses a sealing welding technique of a low-alloy steel pipe plate and a stainless steel pipe of a low-pressure heat exchanger, comprising the following steps: the stainless steel pipe is arranged in a pipe hole in the low-alloy steel pipe plate, the pipe exceeds the end part of the pipe plate by 0 to 1.0mm, the pipe plate is not provided with a bevel edge, and manual argon arc welding or automatic argon arc welding is carried out to the stainless steel pipe and the low-alloy steel pipe plate; the technological parameters thereof when the argon arc welding is carried out are as follows: the voltage is 10 to 16V, the current is 50 to 110A and the welding speed is 0.6 to 1.2mm / s; as a further improvement, welding wires containing more than or equal to 19.5 percent of chromium and more than or equal to 9 percent of nickel by weight percentage are also used when in argon arc welding, and the wire feeding speed is 2.5 to 3.15mm / s. The sealing welding technique has the advantages of having less procedure and simple processing and being time-saving, improves production efficiency, reduces production cost, has no crack for the welding seam, and can meet the long-term and stable operation of the low-pressure heat exchanger.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Method for preparing fluorine-containing phosphate ester surfactant

InactiveCN105080422AControl processSuppress color darkeningTransportation and packagingMixingPhosphateReaction temperature

The invention discloses a method for preparing a fluorine-containing phosphate ester surfactant. The method particularly comprises the following steps: preparing a fluorine-containing polyether toluene solution and a poly-phosphate toluene solution separately; adding toluene into a reaction kettle, and heating to 40 DEG C; continuously dripping the fluorine-containing polyether toluene solution and the poly-phosphate toluene solution into the reaction kettle with an uniform speed, and performing an esterification reaction for 2-4 hours when the reaction temperature is controlled to be 60 DEG C or below; heating to 80 DEG C, and curing for 2-4 hours; removing toluene under reduced pressure to obtain the fluorine-containing phosphate ester product. By adjusting a feeding mode, the reactants are continuously added with the uniform speed in the reaction process, so that the esterification reaction process is effectively controlled, the ratio of monoester to diesters in the product can be controlled, the color of the product is prevented from being darker, and the product quality is improved.

Owner:焦作超达环保科技有限公司

Risk control method, device, and electronic equipment for electronic transactions

ActiveCN111429145BControl processReduce fratricideBuying/selling/leasing transactionsMarketingRisk ControlRisk level

Owner:SHENZHEN TENCENT COMP SYST CO LTD

Sole trimming device

A sole trimming device relates to an anti-shearing device and comprises a base, supports are arranged on the two sides of the top end of the base, a material conveying machine A is arranged at the top ends of the supports and connected with the supports through screws, a machining module is arranged at the top end of one side of the material conveying machine A, and the bottom end of the machining module is connected with the top end of the base. A material conveying machine B is arranged on one side of the machining module, the bottom end of the material conveying machine B is connected with the top end of the base, a container is arranged at one end of the material conveying machine B, and one end of the container is connected with the base. By means of the device, the shoe containing frame is arranged on the crawler belt, the shape of a shoe sole needing to be trimmed can be smoother, an electromagnet is arranged in a trigger switch, a laser instrument can be triggered to be switched on and off when the electromagnet makes contact with the magnet, the machining time and position of the shoe sole are more accurate, an intelligent host is arranged, and each working procedure during trimming can be accurately controlled.

Owner:广东乐骏新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com