Hydrothermal synthesis method of 4A molecular sieve

A technology of hydrothermal synthesis and molecular sieve, which is applied in the direction of A-type crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of low crystallinity and purity of 4A molecular sieve, low solid phase yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

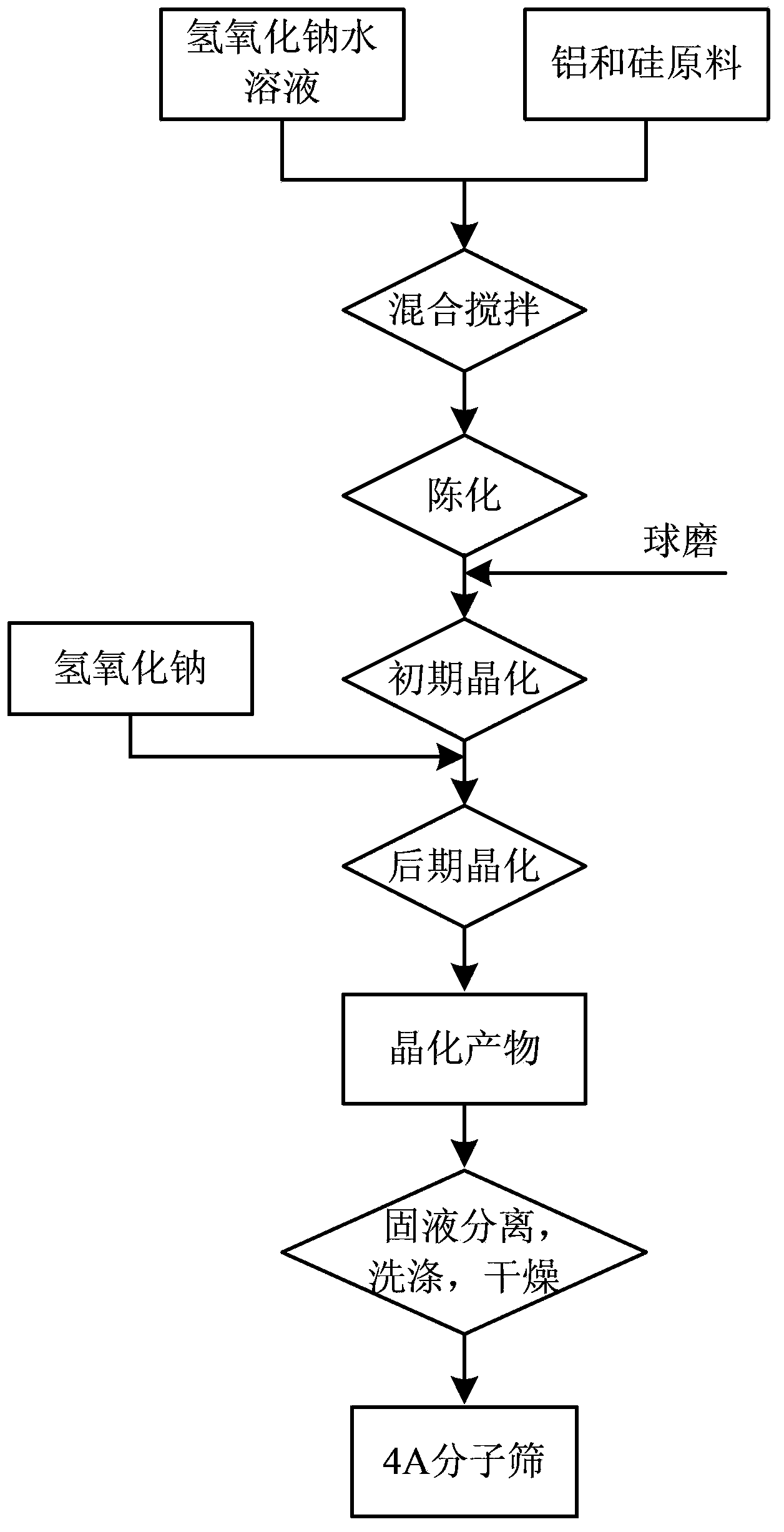

[0078] A kind of hydrothermal synthesis method of 4A molecular sieve, comprises the steps:

[0079] (1) Initial slurry preparation: crush natural kaolin with a kaolinite content of 93.5wt% through a 100-mesh sieve, and roast at 700°C for 3 hours to obtain roasted powder, which is silicon and aluminum raw materials; select roasted powder 20kg, add 50kg24wt % sodium hydroxide aqueous solution, stirring and mixing to obtain initial slurry;

[0080] (2) Aging treatment: aging the initial slurry prepared in step (1) at room temperature for 48 hours to obtain aged slurry;

[0081] (3) Initial crystallization: put the aged slurry obtained in step (2) in an insulated stirring mill for mechanochemical treatment by ball milling, the speed of the agitator is 150r / min, raise the temperature of the system and keep it at 90-100°C, Keep warm for 60 minutes;

[0082] (4) Late stage crystallization: Under the condition of 150r / min ball milling, make the temperature 80~100℃, reduce the ball m...

Embodiment 2

[0090] A kind of hydrothermal synthesis method of 4A molecular sieve, comprises the steps:

[0091] (1) Initial slurry preparation: crush natural kaolin with a kaolinite content of 93.5wt% through a 100-mesh sieve, and roast at 700°C for 3 hours to obtain roasted powder, which is silicon and aluminum raw materials; select roasted powder 20kg, add 40kg10wt % sodium hydroxide aqueous solution, stirring and mixing to obtain initial slurry;

[0092] (2) Aging treatment: aging the initial slurry prepared in step (1) at room temperature for 48 hours to obtain aged slurry;

[0093] (3) Initial crystallization: put the aged slurry obtained in step (2) in an insulated stirring mill for mechanochemical treatment by ball milling, the speed of the agitator is 150r / min, raise the temperature of the system and keep it at 90-100°C, Keep warm for 20 minutes;

[0094] (4) Later stage crystallization: Under the condition of 150r / min ball milling, slowly add 7kg of solid sodium hydroxide to th...

Embodiment 3

[0100] A kind of hydrothermal synthesis method of 4A molecular sieve, comprises the steps:

[0101] (1) Preparation of initial slurry: crush coal-series kaolin with a kaolinite content of 91.6wt% through a 100-mesh sieve, and roast at 850°C for 2 hours to obtain roasted powder, which is silicon and aluminum raw materials; select roasted powder 25kg, add Add 100 g of water reducer sodium hexametaphosphate to 40 kg of 15 wt % sodium hydroxide aqueous solution, stir and mix to obtain initial slurry;

[0102] (2) Aging treatment: aging the initial slurry prepared in step (1) at room temperature for 24 hours to obtain aged slurry;

[0103] (3) Initial crystallization: place the aged slurry obtained in step (2) in an insulated stirring mill, perform mechanochemical treatment, raise the temperature of the system and keep it at 80-95°C, keep it warm for 1 hour, and perform initial crystallization;

[0104] (4) Later stage crystallization: under the condition of 600r / min ball milling,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com