Preparation method of nano SAPO (Silicon Aluminum Phosphate)-34 molecular sieve

A technology of SAPO-34 and molecular sieves, which is applied in the field of preparation of nano-SAPO-34 molecular sieves by mixing and synthesizing nanometer SAPO-34 molecular sieves at low temperature in an ultra-concentrated system. Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A kind of nanometer SAPO-34 molecular sieve is mixed and synthesized at low temperature with ultra-concentrated system, and the concrete steps of its preparation method are as follows:

[0026] Step 1, adding the aluminum source into phosphoric acid and stirring thoroughly to obtain a mixed solution A, and standing in the ice-water mixture for 5-30 minutes. Aluminum source contains Al 2 o 3 , the aluminum source is sodium metaaluminate (Al 2 o 3 content 50%), pseudoboehmite (Al 2 o 3 content 75%) and alumina (Al 2 o 3 Content 99%) in one or more; phosphoric acid contains P 2 o 5 (P 2 o 5 content 85%); among them, Al 2 o 3 with P 2 o 5 The molar ratio is 0.1-2.

[0027] In step 2, the silicon source and the template are mixed successively to obtain a mixed solution B, and the mixed solution B is stirred in an ice bath for 5-20 min. Silicon source contains SiO 2 , the silicon source is white carbon black (SiO 2 content greater than 99%) and silica sol (S...

Embodiment 1

[0031] In the present embodiment, the steps of the preparation method of nanometer SAPO-34 molecular sieve are as follows:

[0032] Step 1: Weigh 3.7g of pseudo-boehmite and add it to 5.76g of phosphoric acid, stir well to obtain mixed solution A, and let it stand in the ice-water mixture for 5-30min.

[0033] Step 2: Weigh 1.3 g of silica sol and 21 g of tetraethylammonium hydroxide (TEAOH content 35%), mix them, and stir in an ice bath for 20 minutes to obtain a mixed solution B.

[0034]Step 3: Slowly add the mixed solution B to the mixed solution A under ice bath conditions, and fully stir for 30 minutes to obtain a uniform mixed solution C, and then age the uniform mixed solution C for 15 hours at room temperature to obtain a uniform gel mixture. The proportion of homogeneous gel mixture is Al 2 o 3 :P 2 o 5 : SiO 2 :TEAOH=1:0.95:0.7:2.

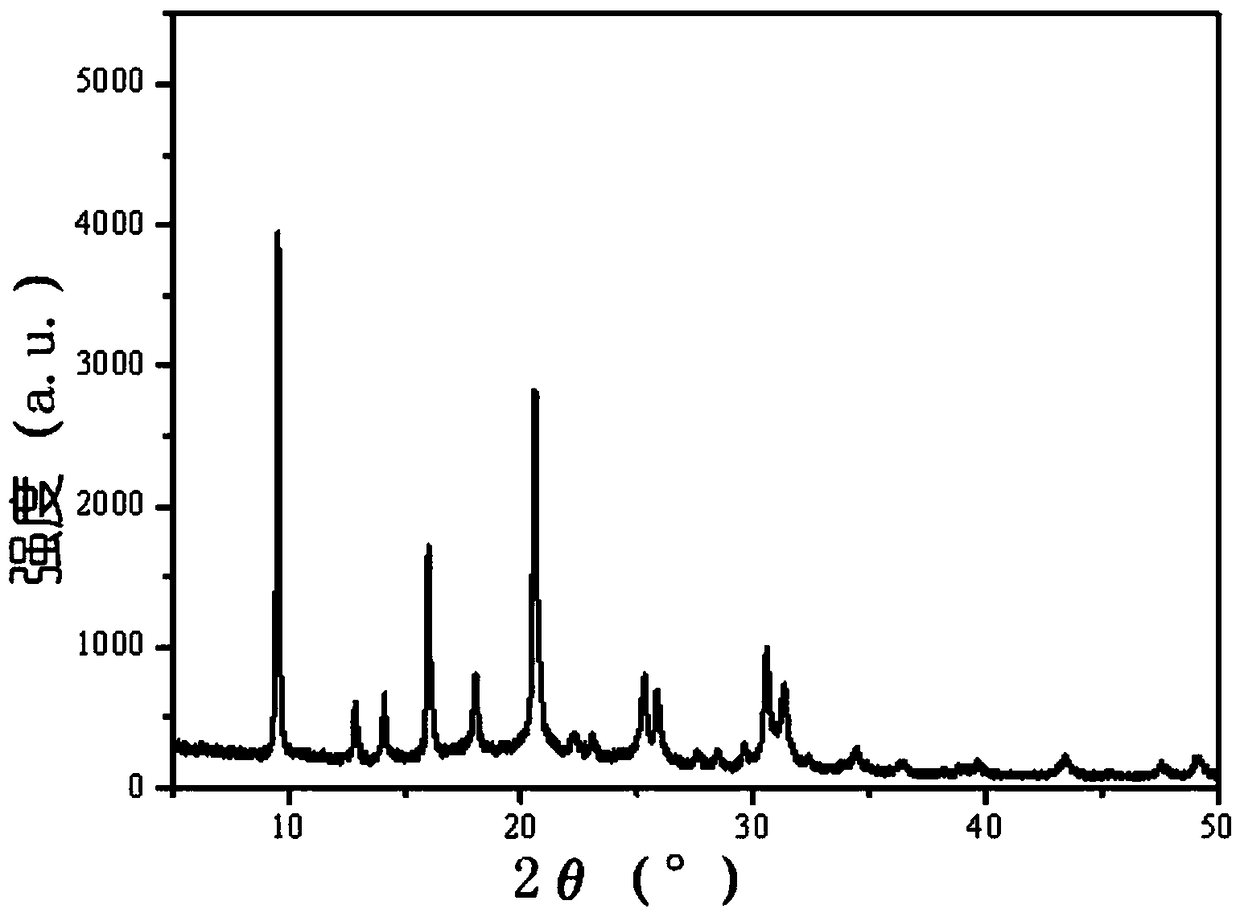

[0035] Step 4: Transfer the homogeneous gel mixture obtained in Step 3 to a stainless steel autoclave lined with polytetrafluoroe...

Embodiment 2

[0037] In this example, the preparation method of nano-SAPO-34 molecular sieve is similar to Example 1, the difference is that Al 2 o 3 with P 2 o 5 The molar ratio is 0.1, such as figure 2 As shown, the finally obtained SAPO-34 molecular sieve has poor crystallinity and many amorphous products appear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com