Automatic walnut shell and kernel mixture airflow sorting machine

An air separation and mixture technology, which is applied in the direction of separating solids from solids by air flow, solid separation, cyclone devices, etc., can solve the problems of inability to achieve adjustment, poor effect, lack of dust removal devices, etc., to reduce extraction. The process of distracting wood, reducing the factors of human operation, and protecting the effect of environmental sanitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

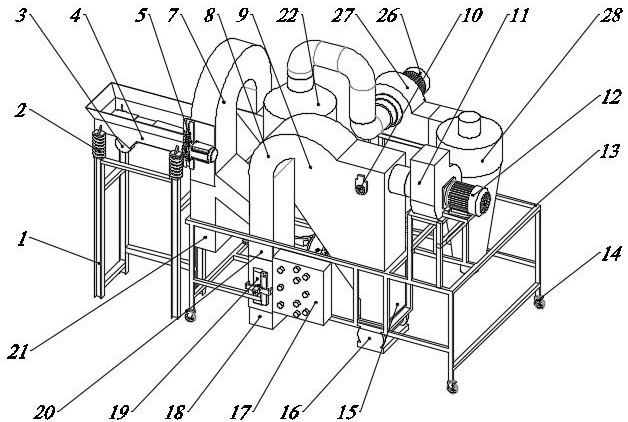

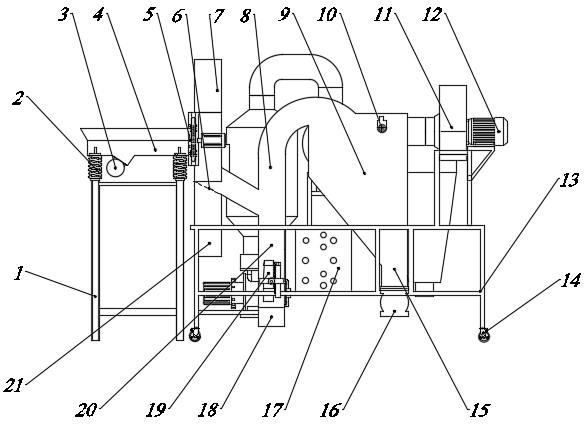

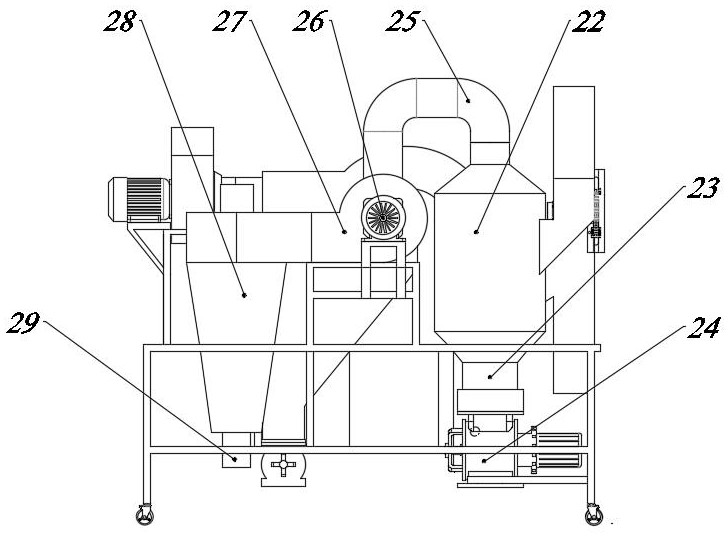

[0021] see Figure 1-Figure 6 , the present invention provides the following technical solutions: a kind of automatic mobile walnut shell kernel mixture airflow sorting machine, including vibrating feeder 4, automatic material limiting air conditioning device 5, distracting wood settling box 22, cyclone dust collector 28 , automatic height adjustment device 19 for walnut kernel discharge port, circuit control cabinet 17, walnut shell unloading box 9, negative pressure fan 11, 27, vibration feeder 4 is equipped with damping spring 2 and vibration motor 3, vibration motor 3 The amplitude and frequency are controlled by the frequency converter to control the material flow of the mixture of walnut shells and kernels; the automatic material limiting and air regulating device 5 is driven by the servo motor 5-1 to rotate the gear 5-2, and the gear 5-2 meshes with the rack 5-3 to move, and the gear 5-2 moves. The bar 5-3 is fixed with the material-limiting air-regulating plate 5-7, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com