Sealing welding technique of low-alloy steel pipe plate and stainless steel pipe of low-pressure heat exchanger

An alloy steel pipe and stainless steel technology, applied in metal processing equipment, welding media, manufacturing tools, etc., can solve the problems of low production efficiency, cumbersome processing, and high cost, and achieve the effects of improved production efficiency, good toughness, and simple processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

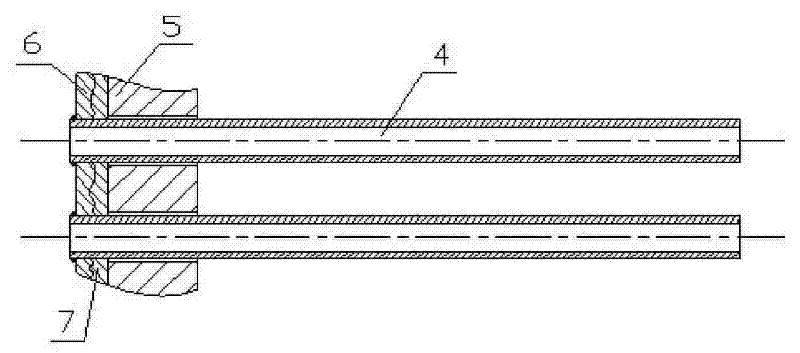

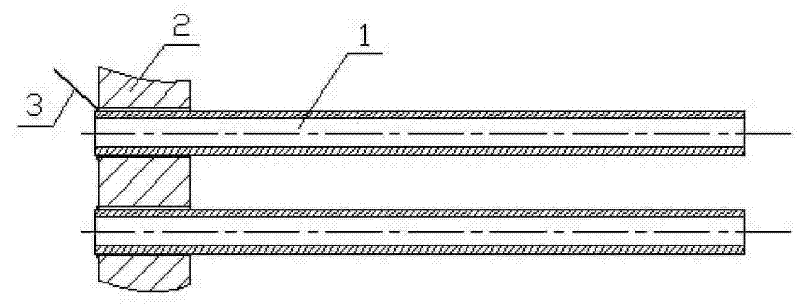

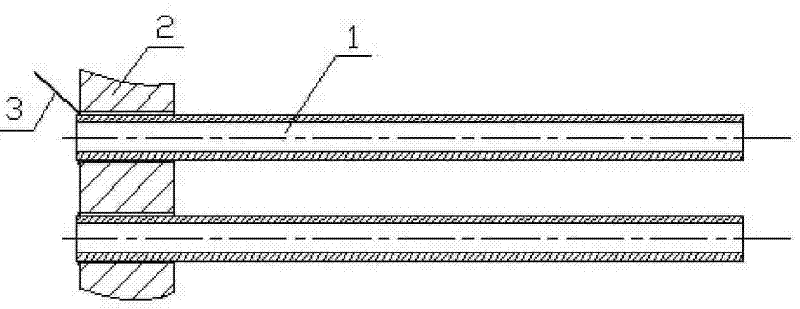

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0011] The seal welding process of low-pressure heater low-alloy steel pipe plate and stainless steel pipe of the present invention, by figure 2 As shown, it includes the following steps: install the stainless steel pipe 1 in the tube hole in the low alloy steel pipe plate 2, the pipe 1 exceeds the end of the tube plate 2 by 0-1.0mm, the tube plate 2 does not have a bevel, and the stainless steel pipe 1 Carry out manual argon arc welding or automatic argon arc welding with the alloy steel pipe plate 2, and use a welding wire made of ER309 (which contains 23-25% by weight of chromium and 12-14% by weight of nickel) when performing argon arc welding , the process parameters are as follows: voltage 10-16V, current 50-110A, welding speed 0.6-1.2 mm / s, wire feeding speed 2.5-3.15 mm / s.

[0012] When austenitic stainless steel is welded to low alloy steel, due to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com