Preparation method of polyvinyl alcohol

A polyvinyl alcohol and polyvinyl acetate technology, which is applied in the field of polyvinyl alcohol preparation, can solve the problems that the process technology and equipment cannot meet the requirements, the quality and output are unsatisfactory, and the low-viscosity PVA is difficult to form, etc. Polymerization residence time, good molding, and the effect of improving product polymerization rate and output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

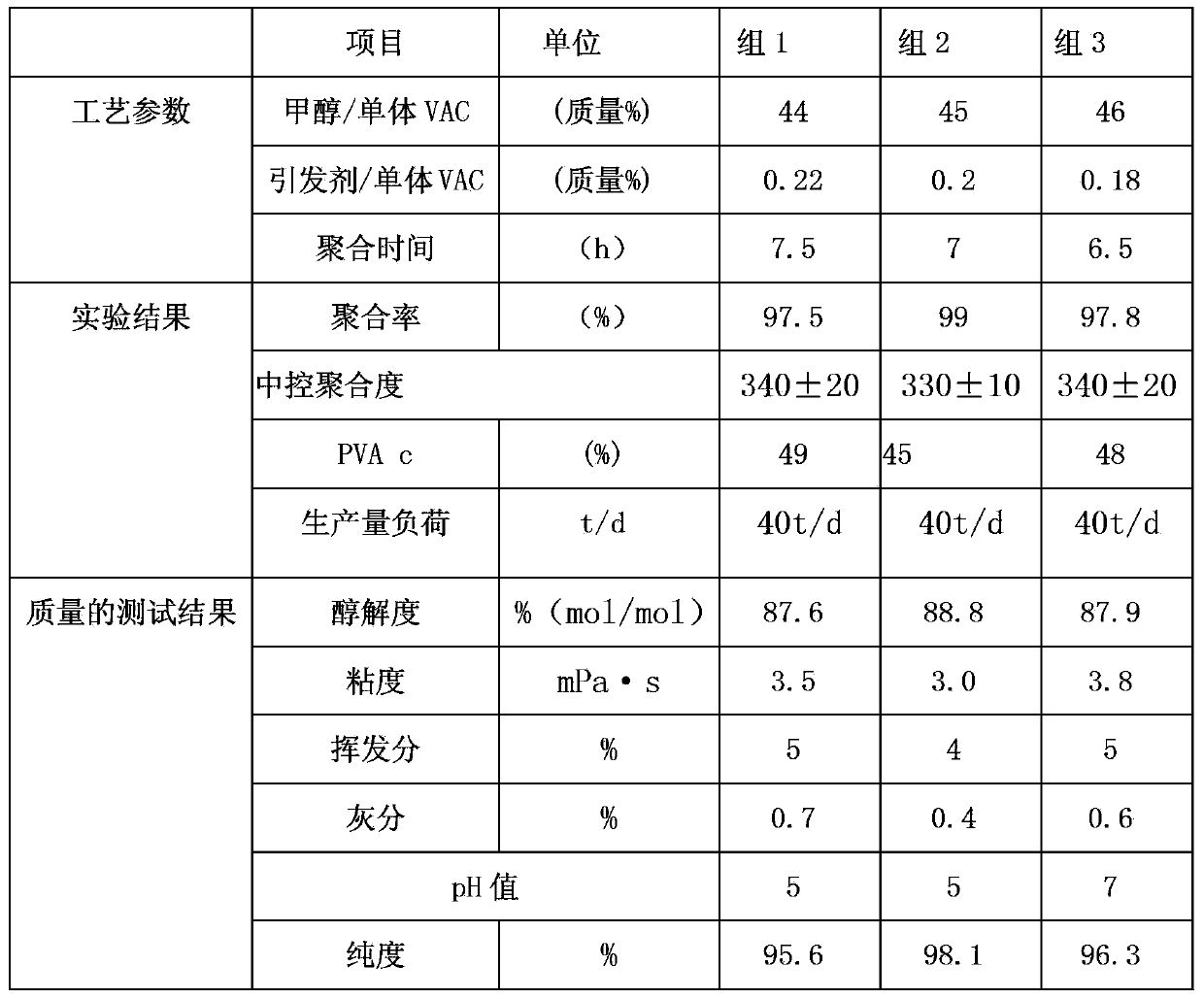

Embodiment 1

[0018] The preparation method of the PVA product of embodiment 1 degree of polymerization 300

[0019] 1. Specific operation steps

[0020] Add tert-butyl peroxypivalate to the solvent methanol at -5°C; preheat vinyl acetate, methanol and initiator methanol solution to 60°C, and the preheated material enters a 22.8 cubic meter agitator And the first-stage reaction kettle of the reflux condenser, the reaction temperature is 66°C, the materials are continuously added, and the residence time is 2.5h. Then enter the second-stage reactor to continue polymerization, the average residence time of the material in the second-stage reactor is about 2.5h, and then pass into the third-stage reactor. After the reaction, unreacted monomers are blown out with methanol steam, and the polyvinyl acetate after demonomerization is diluted with methanol and sent to the alcoholysis process. Send the obtained polyvinyl acetate methanol solution into the alcoholysis machine, and add alkali methanol...

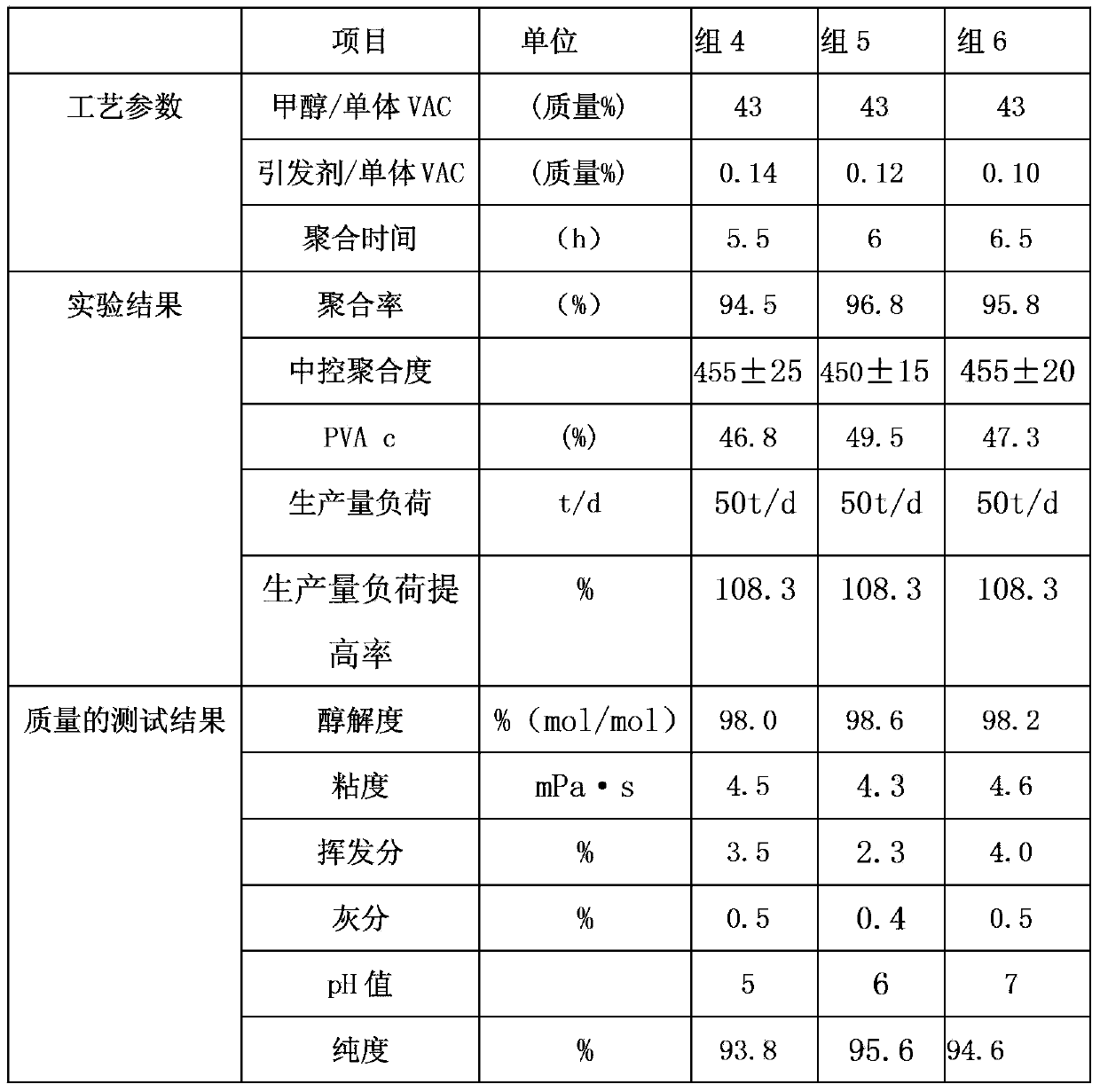

Embodiment 2

[0023] The preparation method of the PVA product of embodiment 2 degree of polymerization 400

[0024] 1. Specific operation steps

[0025] Add tert-butyl peroxypivalate to the solvent methanol at -5°C; preheat vinyl acetate, methanol and initiator methanol solution to 60°C, and the preheated material enters a 22.8 cubic meter agitator And the first-stage reaction kettle of the reflux condenser, the reaction temperature is 65°C, the materials are continuously added, and the residence time is 2h. Then enter the second-stage reactor to continue polymerization. The average residence time of the materials in the second-stage reactor is about 2 hours, and then pass into the third-stage reactor. After the reaction, unreacted monomers are blown out with methanol steam, and the polyvinyl acetate after demonomerization is diluted with methanol and sent to the alcoholysis process. Send the obtained polyvinyl acetate methanol solution into the alcoholysis machine, and add alkali methan...

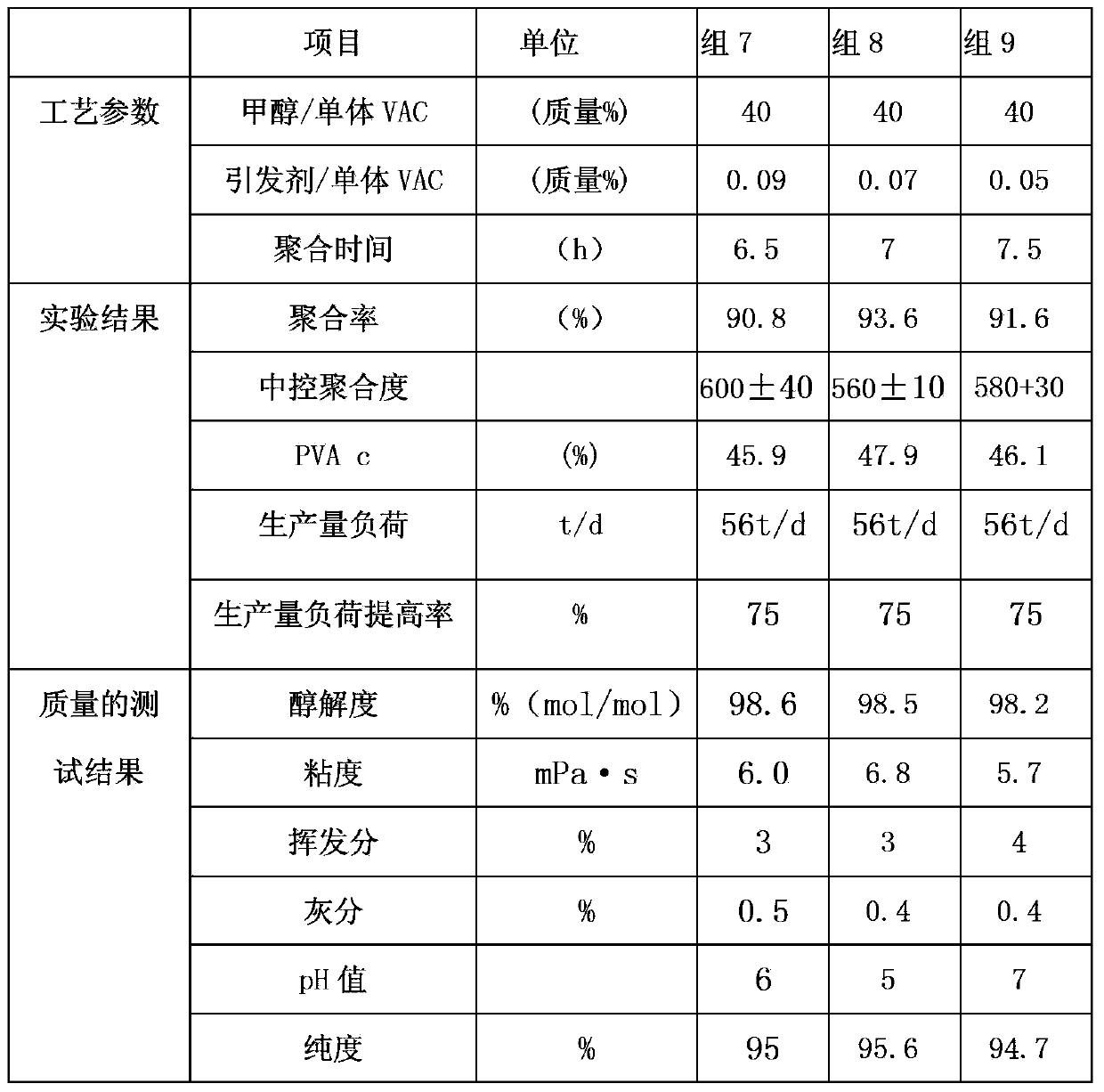

Embodiment 3

[0028] The preparation method of the PVA product of embodiment 3 degree of polymerization 500

[0029] 1. Specific operation steps

[0030] Add tert-butyl peroxypivalate to the solvent methanol at -5°C; preheat vinyl acetate, methanol and initiator methanol solution to 60°C, and the preheated material enters a 22.8 cubic meter agitator And the first-stage reaction kettle of the reflux condenser, the reaction temperature is 65°C, the materials are continuously added, and the residence time is 1.5h. Then enter the second-stage reactor to continue polymerization, the average residence time of the material in the second-stage reactor is about 1.5h, and then pass into the third-stage reactor. After the reaction, unreacted monomers are blown out with methanol steam, and the polyvinyl acetate after demonomerization is diluted with methanol and sent to the alcoholysis process. Send the obtained polyvinyl acetate methanol solution into the alcoholysis machine, and add alkali methanol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com