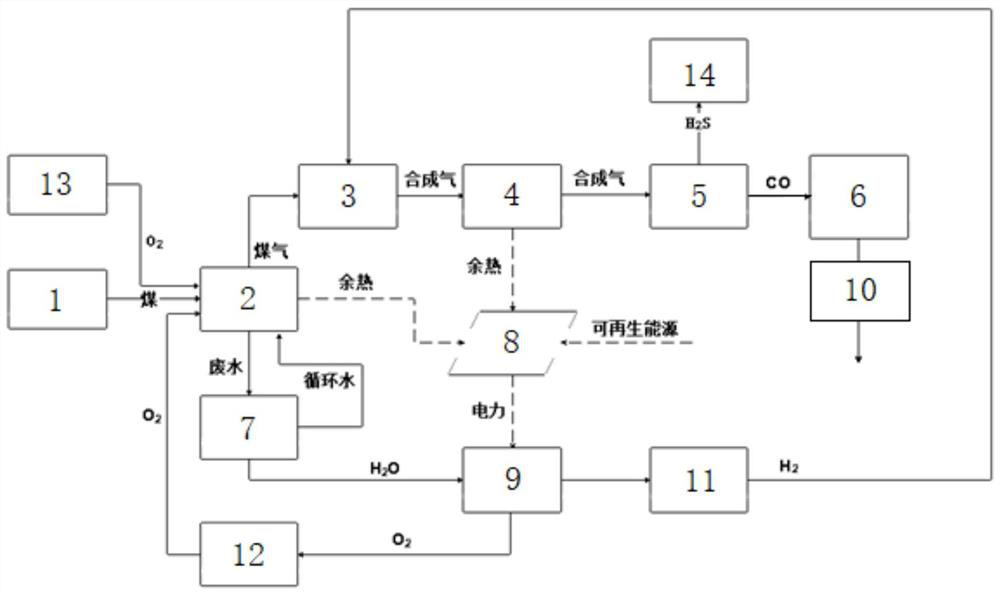

System for simplifying coal-to-methanol production by adjusting carbon-hydrogen ratio with hydrogen and working method of system

A coal-to-methanol and carbon-to-hydrogen ratio technology, applied in the field of coal chemical industry, can solve the problem of large space for emission reduction and utilization, and achieve the effects of reducing production and operation costs, reducing energy consumption, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In the system of the present invention, when methanol is the target product:

[0042] Coal preparation unit 1 crushes, grinds or otherwise processes the raw coal according to the gasification process, and the coal input volume is 162.8t / h. The O produced by the electrolytic hydrogen production unit 9 2 Enter the oxygen collection unit 12 for collection, and then enter the coal gasification unit 2 together with the raw coal produced by the coal preparation unit 1 and the oxygen produced by the air separation unit 13 for coal gasification reaction, and adjust the oxygen-to-coal ratio (O / C) of the coal gasification unit 2 = 1.01 to 1.05. Carbon in coal is partially oxidized to produce H 2 , CO, CO 2 and H 2 O and others such as H 2 S, CH 4 and other gases, the crude gas produced is washed and sent to the carbon-hydrogen ratio adjustment unit 3 for water-gas shift reaction, and the waste water generated during the washing process of the coal gasification unit 2 is sen...

Embodiment 2

[0050] In the system of the present invention, when methane is the target product:

[0051] H in synthesis gas to methanol or methane unit 2 The mol ratio with CO is 3.05~3.15, and other conditions are with embodiment 1.

[0052] After testing, the total CO of the system 2 The emission is 202t / h, and the daily methane production is 7.56 million Nm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com