Aluminum profile vacuum machining control system based on waste heat recovery

A waste heat recovery and control system technology, applied in the field of aluminum profiles, can solve the problems of large processing system structure, waste of energy, and many supporting structures, achieve strong weather resistance and corrosion resistance, ensure control effect, and good corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

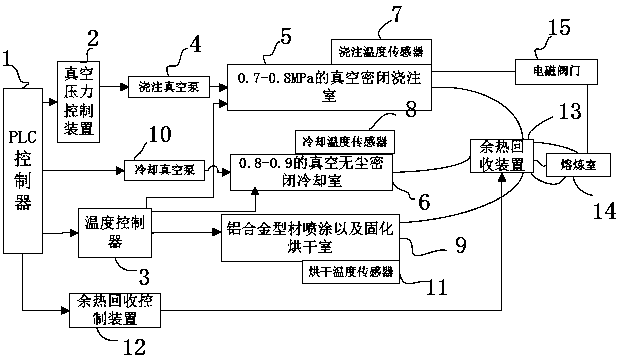

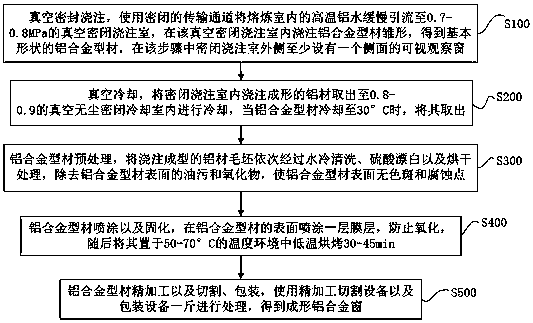

[0024] like figure 1 As shown, the vacuum processing control system for aluminum profiles based on waste heat recovery includes a vacuum pressure controller 2 connected to a PLC controller 1, a temperature controller 3 and a waste heat recovery control device 12, wherein: the vacuum pressure controller 2, through the pouring vacuum pump 4 is connected to control its vacuum state in the vacuum-tight pouring chamber 5 of 0.7-0.8 MPa, and at the same time it is connected to the vacuum and dust-free airtight cooling chamber 6 of 0.8-0.9 through the cooling vacuum pump 10 to control its vacuum state; the temperature controller 3, respectively Connect the pouring temperature sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com