A kind of preparation method of flake silver powder

A flake silver powder and silver powder technology, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problem of flake silver powder not being flat enough, and achieve the effect of smooth surface, good reproducibility, and short storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Weigh 5 kg of silver nitrate, dissolve it in 20 L of deionized water, prepare a silver nitrate solution with a mass concentration of 20% wt, and control the temperature at 15-16° C. in a water bath.

[0050] Weigh 2.7kg of ascorbic acid, dissolve it in 60L of deionized water, add 0.01kg of gum arabic and 0.05kg of polyvinylpyrrolidone, control the temperature of the solution at 15±1°C, stir for 30min, and adjust the pH of the solution to 1.2±0.1 by adding nitric acid.

[0051] Add the silver nitrate solution into the reducing agent solution at a constant flow rate of 60 L / min. After the addition is complete, continue stirring for 15 min to obtain a post-reaction solution.

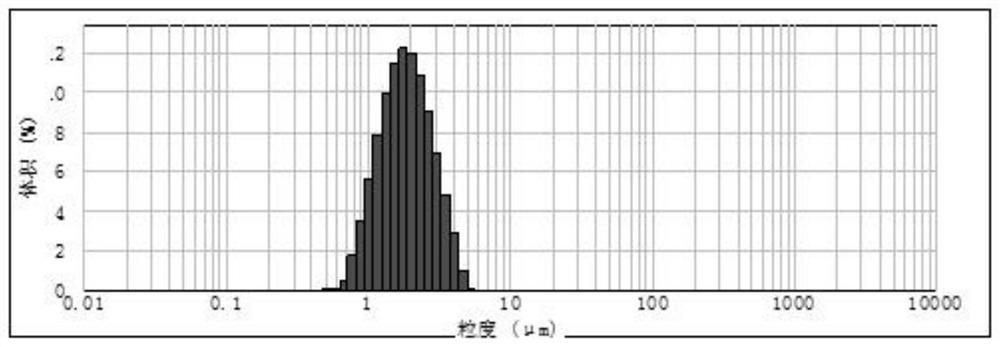

[0052] The resulting reaction liquid was left to settle and settle until the layers were separated, then the supernatant liquid was removed, and the lower precipitate was repeatedly washed with deionized water until the conductivity was less than 20 μS / cm, filtered and dried to obtain a spherical silv...

Embodiment 2

[0055] Weigh 5 kg of silver nitrate, dissolve it in 15 L of deionized water, prepare a silver nitrate solution with a mass concentration of 25% wt, and control the temperature at 10-11° C. in a water bath.

[0056] Weigh 2.7kg of ascorbic acid, dissolve it in 70L of deionized water, add 0.02kg of gelatin and 0.02kg of polyethylene glycol, control the temperature of the solution at 10-11°C, stir for 30min, and adjust the pH of the solution to 1.5±0.1 by adding nitric acid.

[0057] Add the silver nitrate solution into the reducing agent solution at a constant flow rate of 60 L / min. After the addition is complete, continue stirring for 15 min to obtain a post-reaction solution.

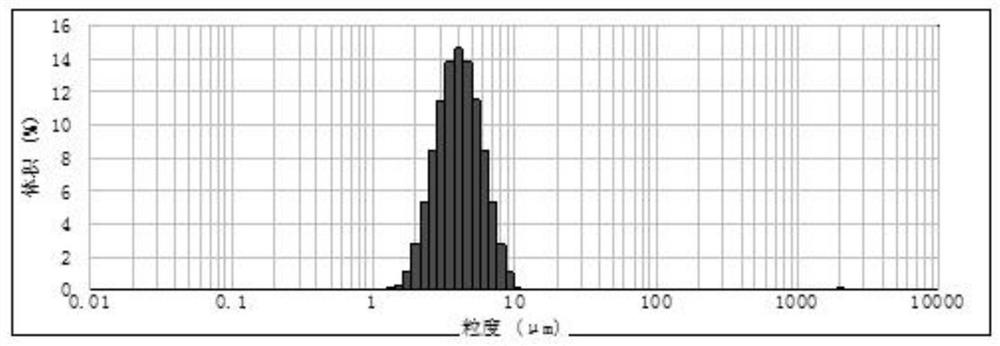

[0058] The resulting reaction liquid was left to settle and settle until the layers were separated, then the supernatant liquid was removed, and the lower precipitate was repeatedly washed with deionized water until the conductivity was less than 20 μS / cm, filtered and dried to obtain a spherical silver ...

Embodiment 3

[0061] Weigh 5 kg of silver nitrate, dissolve it in 12 L of deionized water, and prepare a silver nitrate solution with a mass concentration of 29.4% wt, and control the temperature at 18-20° C. in a water bath.

[0062] Weigh 3.0kg of ascorbic acid, dissolve it in 55L of deionized water, add 0.08kg of polyvinylpyrrolidone, control the temperature of the solution at 18-20°C, stir for 30min, and adjust the pH of the solution to 1.5±0.1 by adding nitric acid.

[0063] Add the silver nitrate solution into the reducing agent solution at a constant flow rate of 40 L / min. After the addition is complete, continue stirring for 15 min to obtain a post-reaction solution.

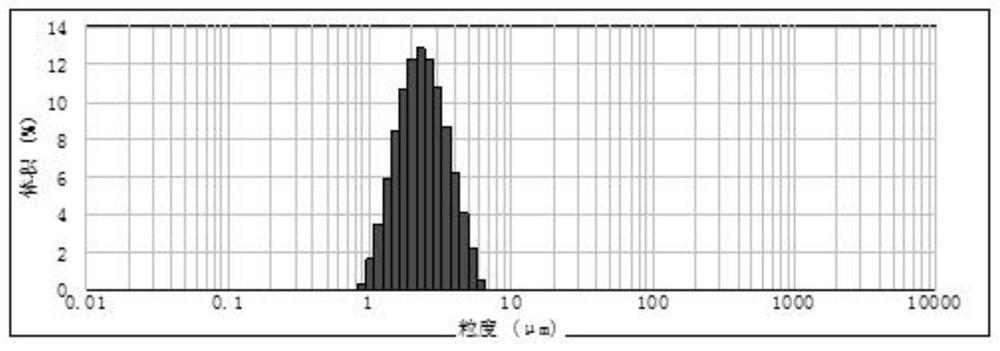

[0064] The resulting reaction liquid was left to settle and settle until the layers were separated, then the supernatant liquid was removed, and the lower precipitate was repeatedly washed with deionized water until the conductivity was less than 20 μS / cm, filtered and dried to obtain a spherical silver powder with a w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com