Pulverizing and screening device for building waste recycling

A construction waste and screening device technology, which is applied in grain processing, etc., can solve the problems of lengthening the crushing time, changing the amount of construction waste, and small mutual extrusion force of waste materials, so as to improve the crushing effect, concentrate the distribution of waste materials, and improve the crushing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

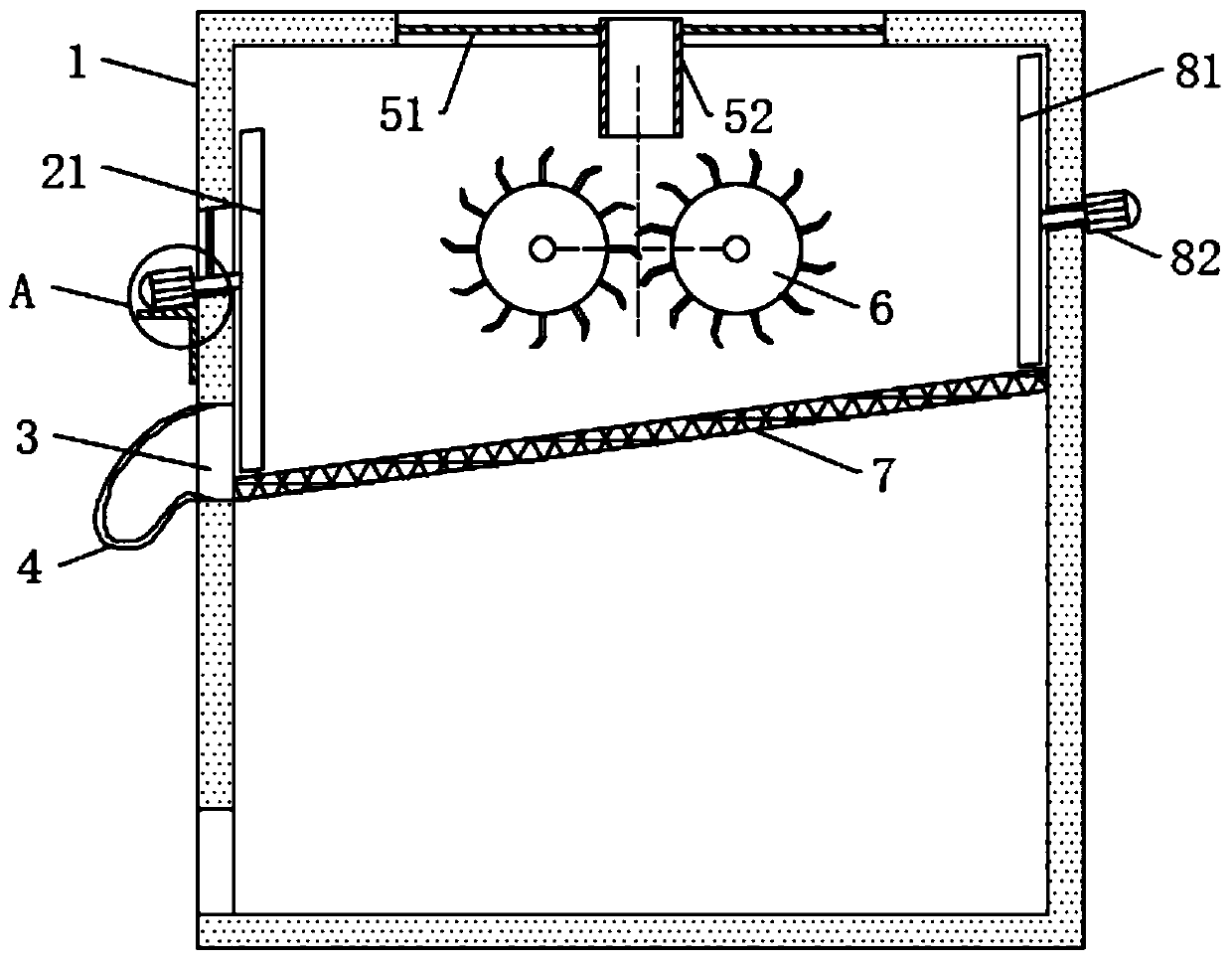

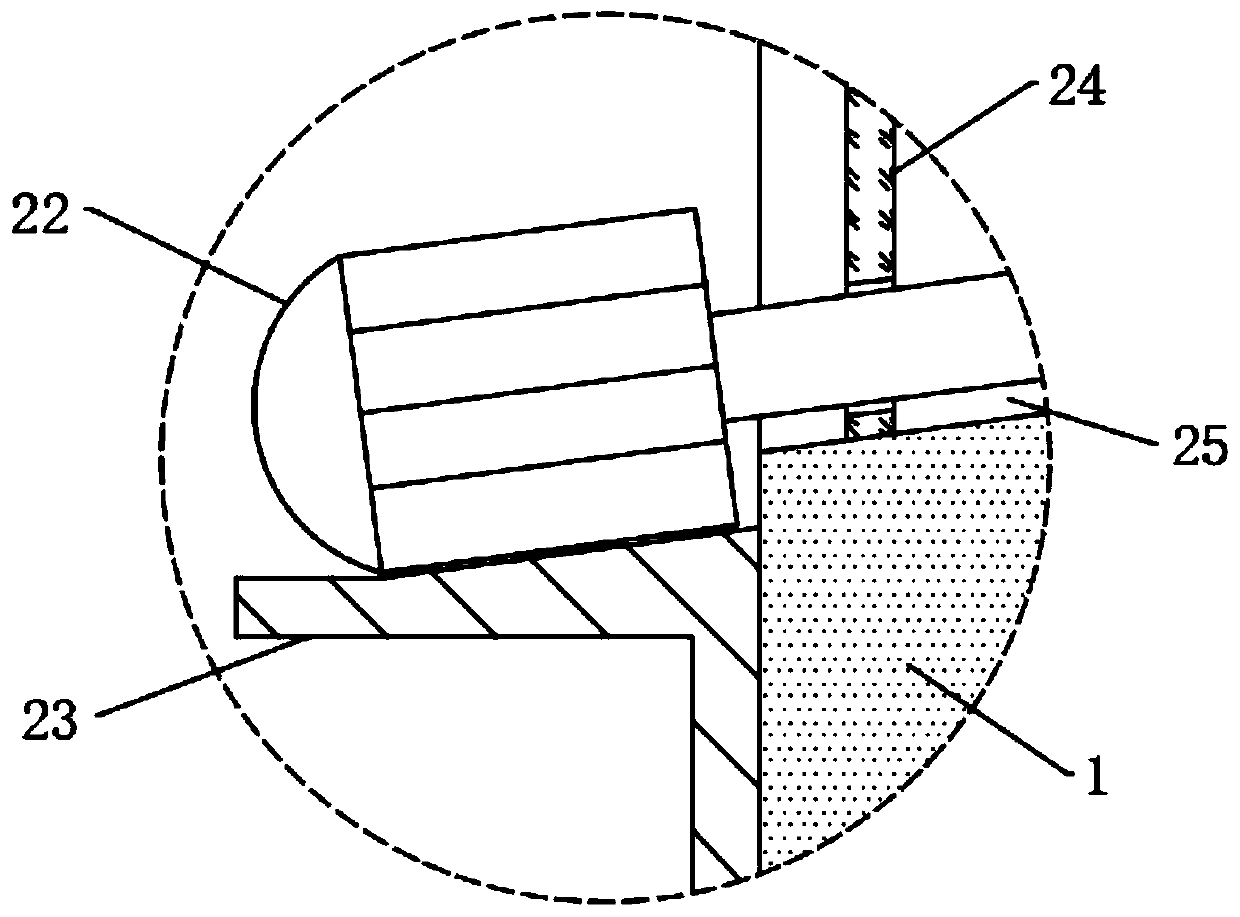

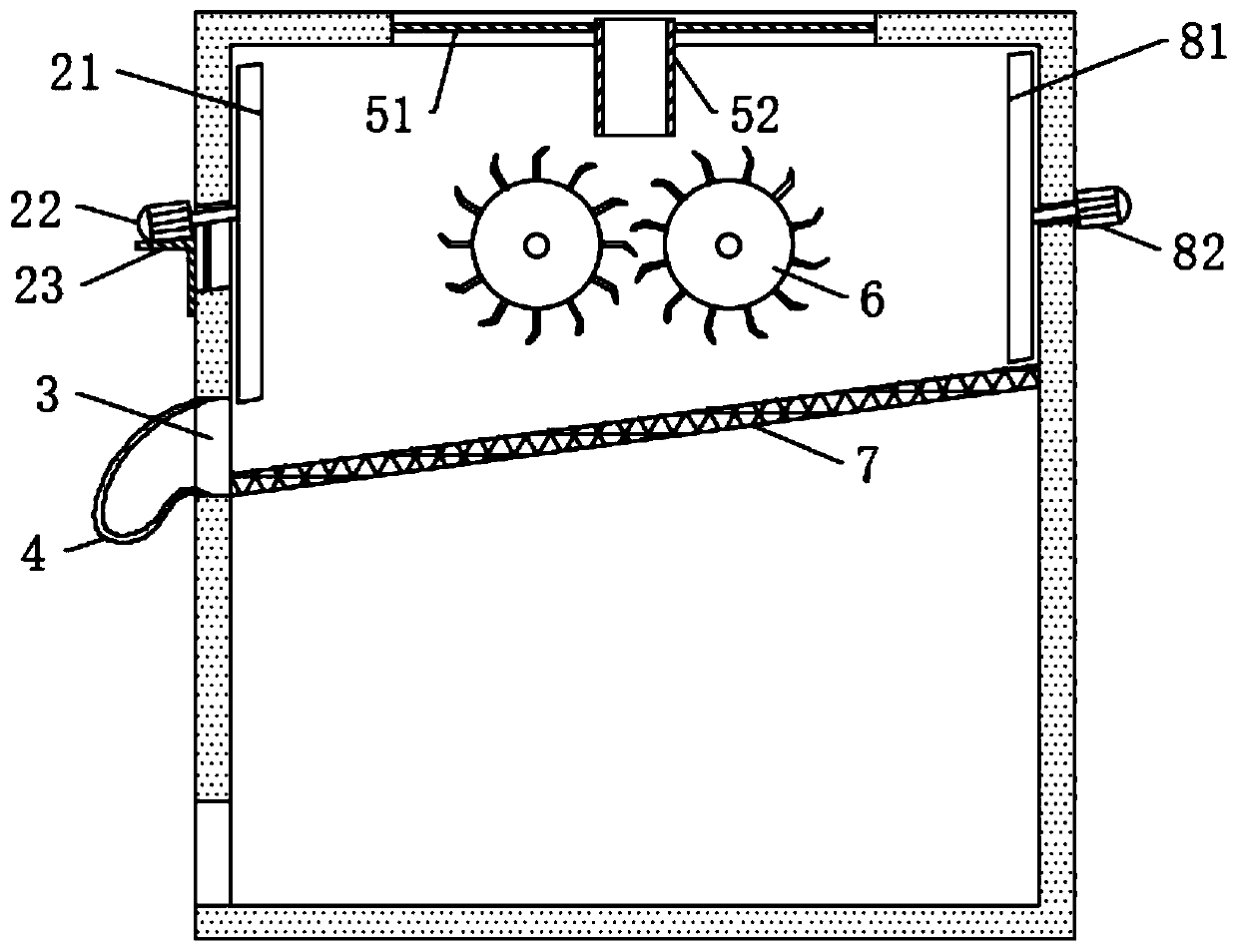

[0040] see figure 1 , a pulverizing and screening device for recycling construction waste, comprising a pulverizing shell 1, a controller (not shown) is arranged on the pulverizing shell 1, and there are two in the pulverizing shell 1 by which are arranged outside the pulverizing shell 1 The driving motor drives and rotates the crushing roller 6 with crushing teeth (the driving motor is not shown, the driving motor is electrically connected to the controller), the rotation directions of the two crushing rollers 6 are opposite, and the crushing teeth on the two crushing rollers 6 The two crushing rollers 6 are engaged with each other, so that the crushing efficiency of the two crushing rollers 6 is higher. The upper end and the left end of the crushing shell 1 are respectively provided with a feeding port and a discharging port, and an inclined setting is fixed between the left and right inner walls of the crushing shell 1. The sieve plate 7 is located on the lower side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com