Titanium tungsten silicon composite powder used for diesel vehicle/steamship tail gas SCR denitration, and preparation method thereof

A diesel vehicle, titanium-tungsten-silicon technology is applied in the field of titanium-tungsten-silicon composite powder for SCR denitration of diesel vehicle/ship exhaust gas and its preparation, which can solve the problem of high production cost, and achieve long service life, strong adsorption, and high temperature resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

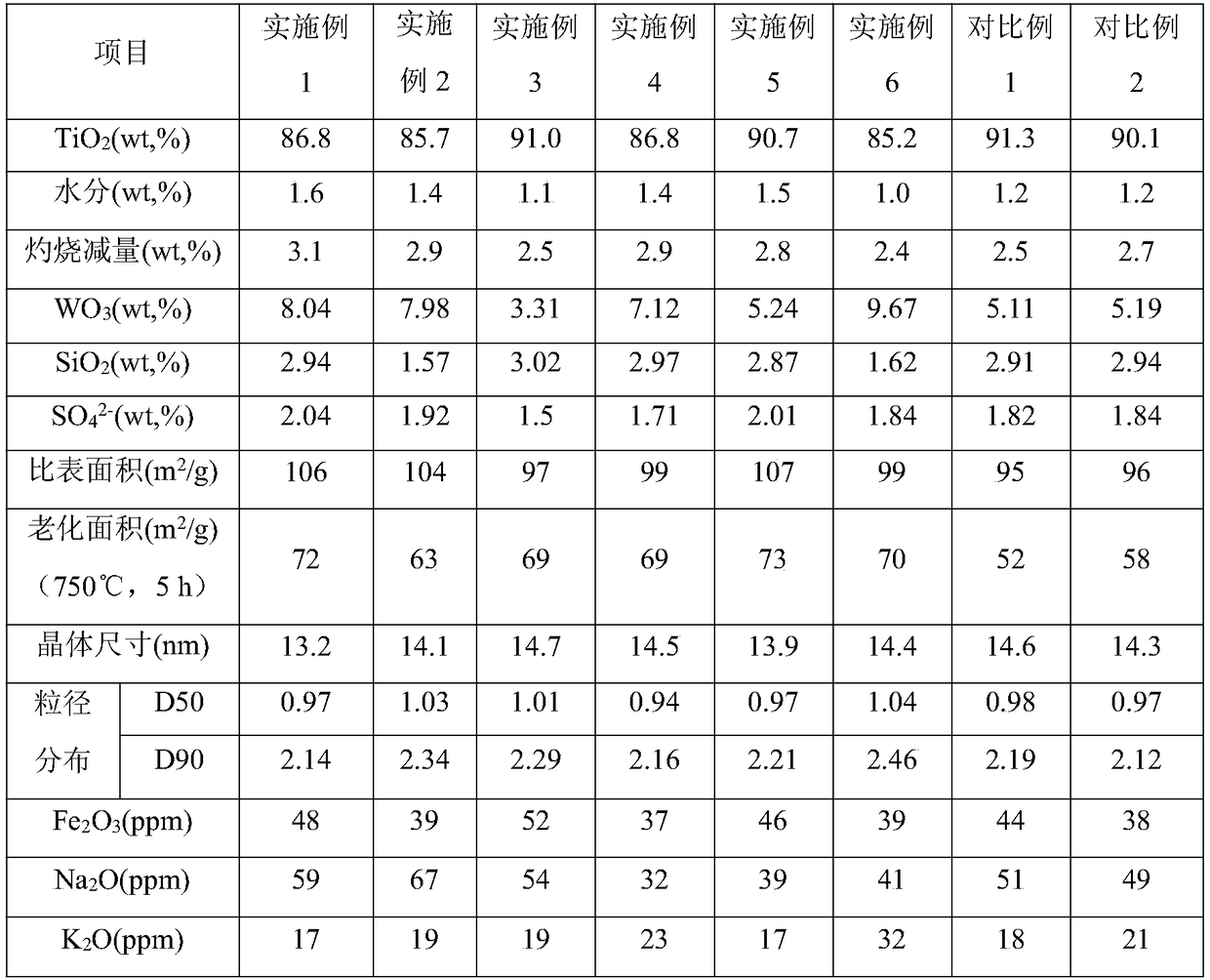

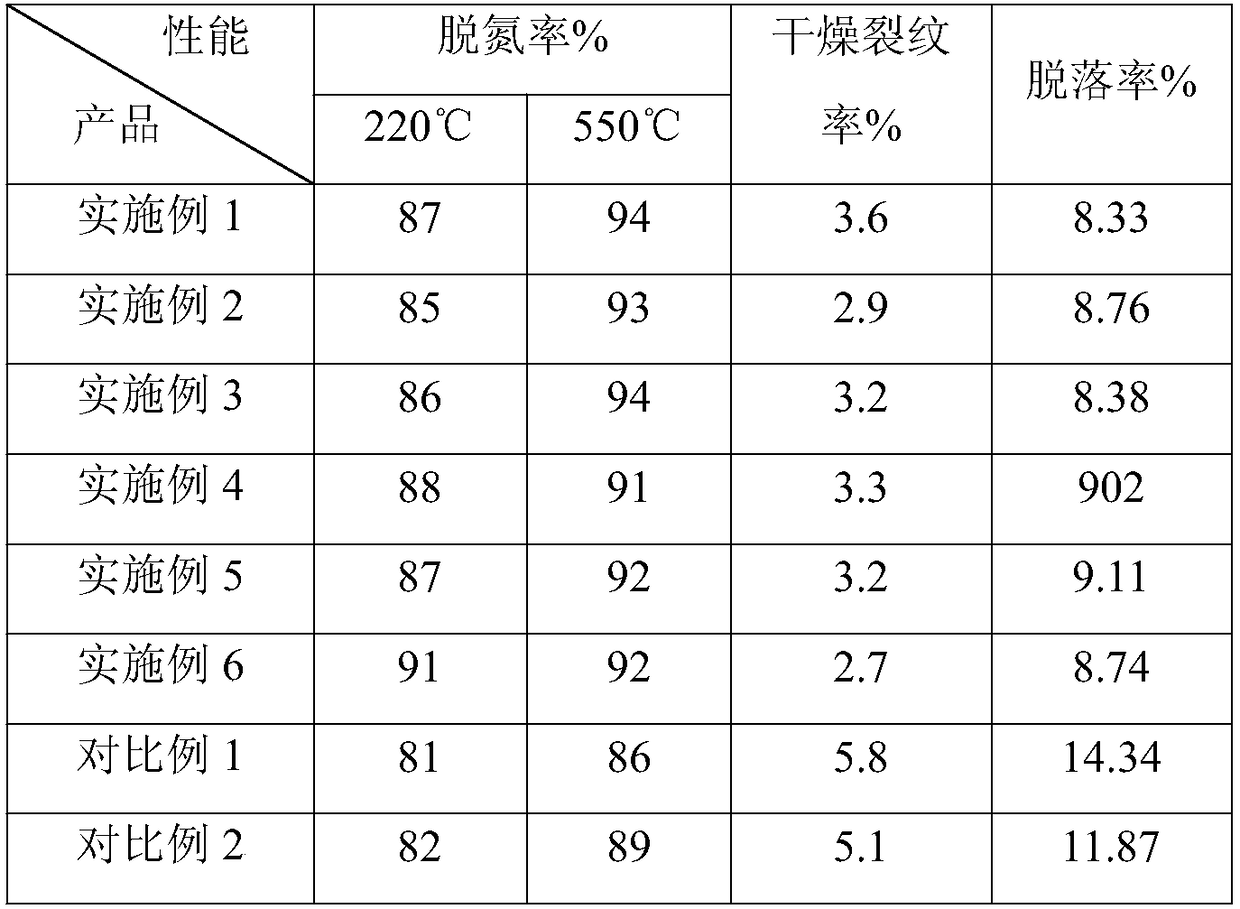

Examples

preparation example Construction

[0030] Specifically, a titanium-tungsten-silicon composite powder for diesel vehicle / ship exhaust SCR denitrification, which is prepared by the following method:

[0031] a. Beat and disperse the metatitanic acid until the mass fraction calculated by titanium dioxide is 22% to 25%, add ammonia water to adjust the pH, stir evenly to obtain a slurry, and set aside;

[0032]b. Beat and disperse metatitanic acid to a mass fraction of 18% to 20% based on titanium dioxide, add ammonia water to adjust pH, then add tungsten source and silicon source, heat and keep warm to obtain a masterbatch;

[0033] c. Mix the slurry obtained in step a and the masterbatch obtained in step b uniformly, then press filter, dry the obtained filter cake, and then calcinate, and pulverize the calcined material to obtain titanium-tungsten-silicon composite powder for SCR denitrification of diesel vehicle / ship exhaust.

[0034] In the present invention, the mass concentration of metatitanic acid as a raw m...

Embodiment 1

[0051] a, weigh 10Kg metatitanic acid (according to TiO 2 One part is added to the reactor with stirring device, and deionized water is added, and the slurry is dispersed until the mass fraction based on titanium dioxide is 23%, and ammonia water is added to adjust the pH to 7.93, and the mixture is evenly stirred to obtain a slurry ,spare;

[0052]b. Add the other part to the reactor with stirring device, add deionized water, beat and disperse until the mass fraction based on titanium dioxide is 20%, add ammonia water to adjust the pH to 7.91, and add ammonium paratungstate (APT) 1.1 to the slurry kg, 1.1kg of silica sol, heated to 75°C and kept for 2 hours, during the process of heating and keeping warm, add ammonia water to keep the pH of the system at 7.5-8.8 to obtain a masterbatch;

[0053] c. Mix and stir the slurry and masterbatch evenly, press filter to obtain block filter cake, dry the filter cake at 250°C for 2 hours, put it into the rotary kiln for calcination, an...

Embodiment 2

[0055] a, weigh 10Kg metatitanic acid (according to TiO 2 One part is added to the reactor with stirring device, and deionized water is added, and the slurry is dispersed until the mass fraction based on titanium dioxide is 23%, and ammonia water is added to adjust the pH to 7.76, and the slurry is obtained by stirring evenly ,spare;

[0056] b. Add the other part to the reactor with stirring device, add deionized water, beat and disperse until the mass fraction based on titanium dioxide is 18%, add ammonia water to adjust the pH to 7.84, and add ammonium paratungstate (APT) 1.1 to the slurry kg, 0.52kg of silica sol, heated to 75°C and kept for 2 hours, during the process of heating and keeping warm, add ammonia water to keep the pH of the system at 7.5-8.8 to obtain a masterbatch;

[0057] c. Mix and stir the slurry and masterbatch evenly, press filter to obtain block filter cake, dry the filter cake at 250°C for 2 hours, put it into the rotary kiln for calcination, and cal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size distribution | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com