Mining timeliness four-wheel drive automatic speed changing multi-mode power driving system

An automatic variable speed, power-driven technology, applied in the direction of power devices, electric power devices, control devices, etc., can solve the problem that mining electric drive vehicles cannot efficiently meet the complex and changing working conditions of coal mines, and achieve improved energy utilization. The effect of high power utilization and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

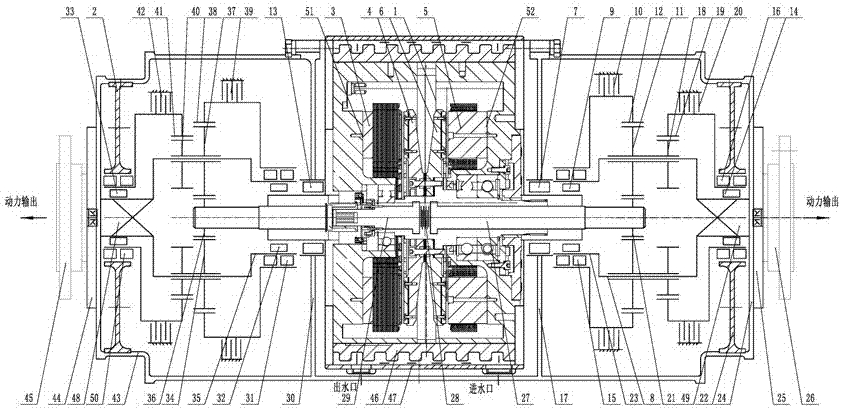

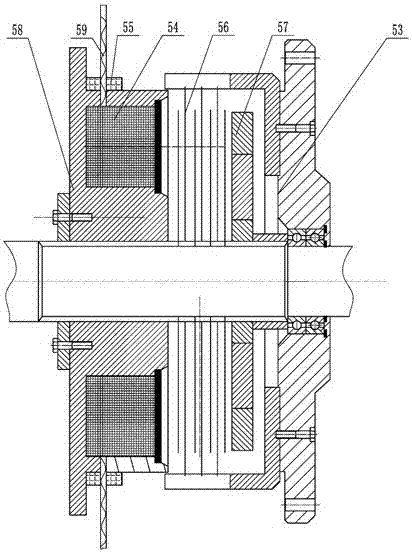

[0016] The invention provides a timely four-wheel drive automatic variable speed multi-mode power drive system for mining, such as figure 1 As shown, it includes a water-cooled central double-drive explosion-proof motor 1, a planetary reduction mechanism I8, a planetary reduction mechanism II34, a left output flange 45 and a right output flange 26. The double-drive explosion-proof motor 1 passes through the left shaft 29 running through the center. and the right shaft 27 are respectively connected with the planetary reduction mechanism I8, the planetary reduction mechanism II34, the left output flange 45 and the right output flange 26, and the junction of the left shaft 29 and the right shaft 27 is provided with a shaft clutch device 28, through which the clutch device 28 The separation and combination of the friction disc realizes the switching of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com