Preparation method of starch adhesive used for artificial board production

A starch adhesive and wood-based panel technology, applied in the direction of starch-derived adhesives, adhesive types, polymer adhesive additives, etc., can solve problems such as endangering the environment and human health, and achieve improved bonding performance and water resistance , The process is simple, and the effect of rapid promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

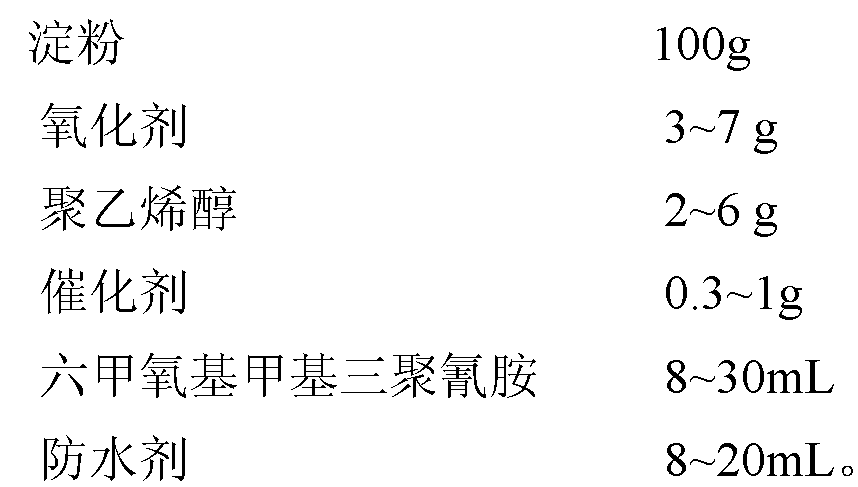

[0019] formula:

[0020]

[0021] Process: Mix 100g cornstarch with 60mL, 1.5mol / L hydrochloric acid to make starch milk with a concentration of 30g / 100g, add 4g ammonium persulfate, put it into a four-necked flask equipped with a stirrer, and acidify at 60°C After 100 minutes of deoxidation, adjust the pH to 6.5, add 14mL of hexamethoxymethylmelamine, 0.5g of catalyst oxalic acid, add 3g of polyvinyl alcohol after 60 minutes of reaction, then raise the temperature to 90°C and keep it for 30 minutes, slowly cool down to 50°C, add 11mL of styrene-butadiene Latex, heat preservation 30min and discharge to obtain the starch adhesive.

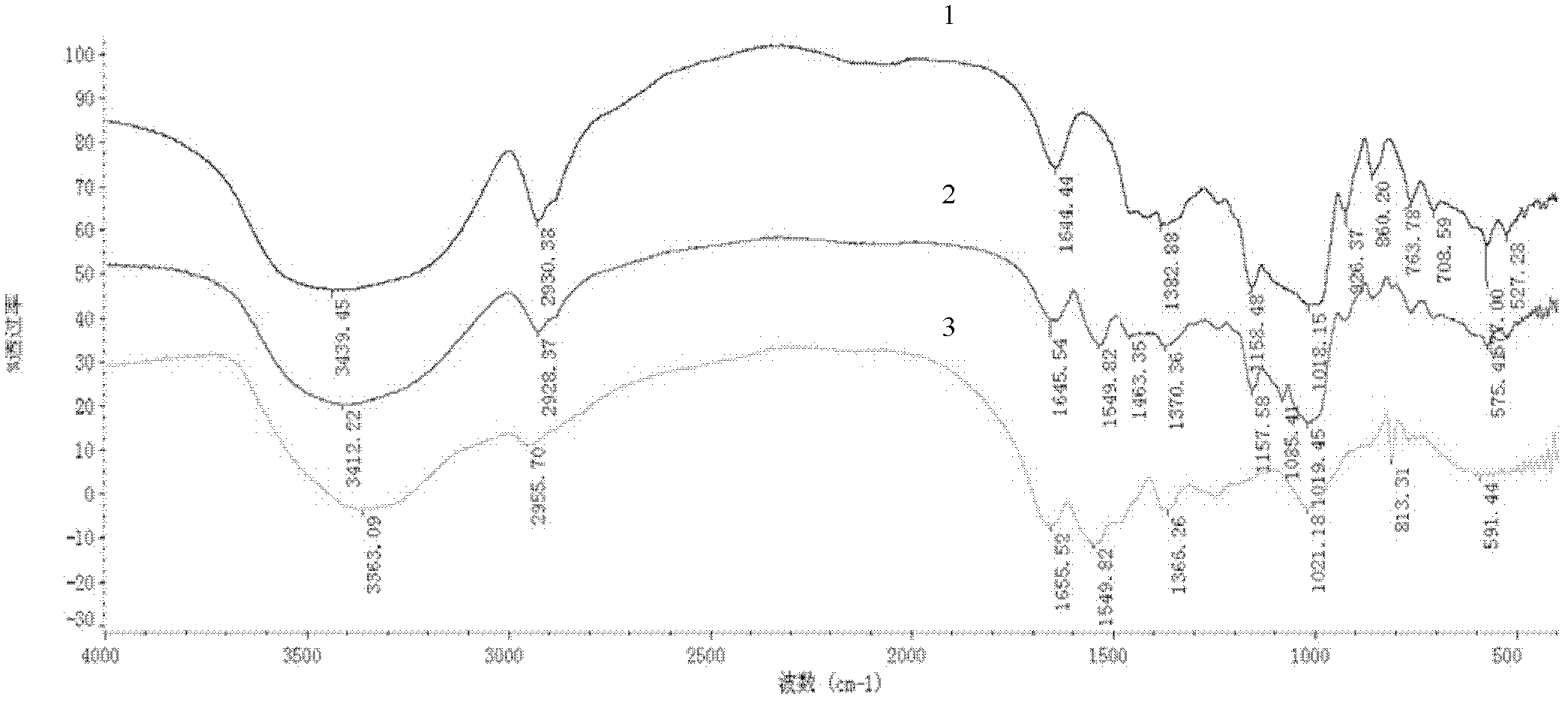

[0022] Corn starch, the prepared starch adhesive, and hexamethoxymethylmelamine were analyzed by infrared spectroscopy, and the results are shown in Figure 1 below. It can be seen from Figure 1 that the infrared spectrum of the reaction product of hexamethoxymethyl melamine and corn starch is roughly similar to that of unmodified corn starch. H...

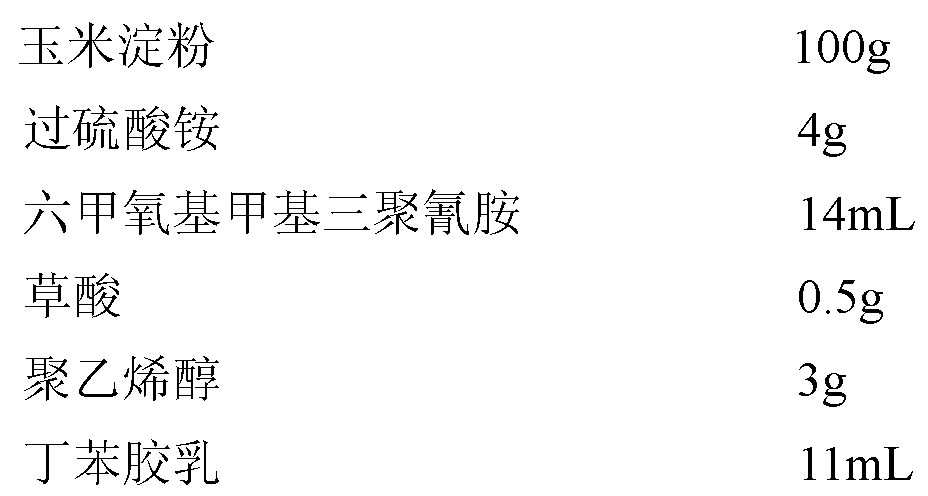

Embodiment 2

[0027]

[0028] Process: Mix 100g of cornstarch with 60mL, 2mol / L hydrochloric acid to make starch milk with a concentration of 40% (w / w), add 5g of ammonium persulfate, put it into a four-necked flask equipped with a stirrer, and heat it at 60°C After acidolysis and oxidation for 90 minutes, adjust the pH to 7, add 22mL hexamethoxymethyl melamine, 0.85g catalyst citric acid, add 2.5g polyvinyl alcohol after 75 minutes of reaction, then raise the temperature to 85°C and keep it for 30min, then slowly cool down to 50°C, Add 16mL of water-repellent styrene-butadiene latex, keep warm for 30min, and discharge to obtain the prepared starch adhesive. The obtained starch adhesive is applied to the pressing of the particleboard, and the internal bonding strength of the obtained particleboard reaches 0.41MPa, which meets the requirement of ≥0.4MPa in the national standard for particleboard, and the water expansion rate of 7.2% meets the requirement of ≤8% in the national standard for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com