Inkjet printing material for bleeding and eduction resistance and high precision

An inkjet material, high-precision technology, applied in textiles, copying/marking methods, lamination, etc., can solve problems not involved in the production of anti-dialysis inkjet materials, and achieve significant stabilization, low odor, and improved fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] An anti-dialysis high-precision inkjet material prepared by the following method:

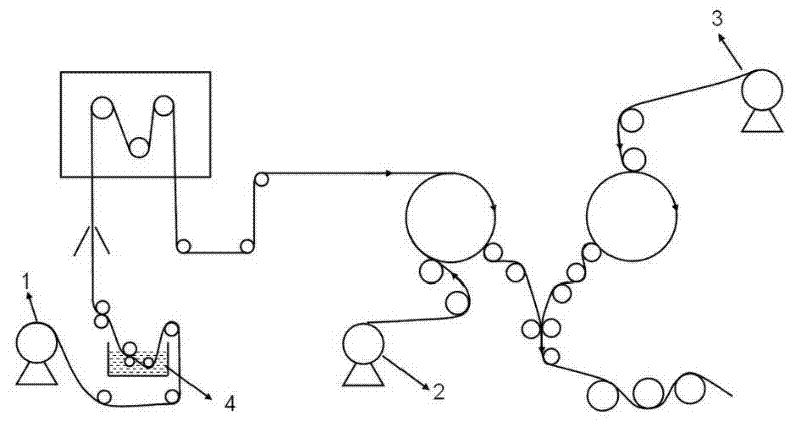

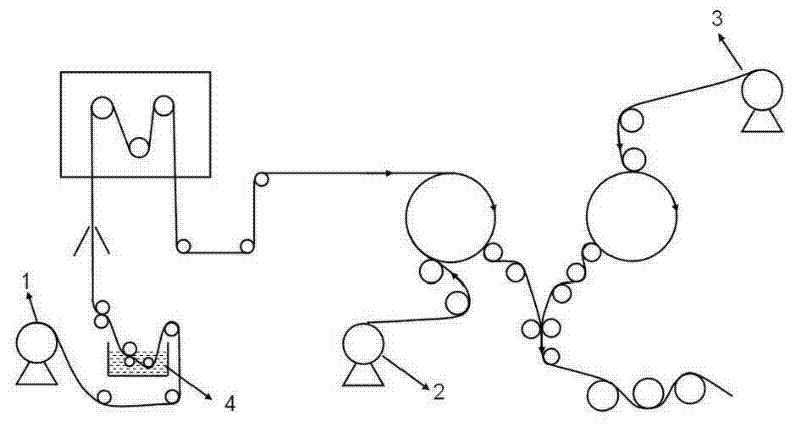

[0032] (1) Using high-strength and low-shrinkage polyester yarn as the raw material, the base fabric after warping, weaving and splitting and winding is used as the skeleton material; (2) The skeleton material in step (1) is dipped, dried and pre-shaped , using double-sided hot-melt lamination of PVC film and then embossing, cooling, shaping and trimming to obtain anti-dialysis high-precision inkjet materials. The preparation process of step (2) is as figure 1 As shown, 1 is the skeleton material, 2 is the base film, 3 is the mask, and 4 is the water-based polyurethane glue.

[0033] The specification of the high-strength and low-shrinkage polyester yarn is 1000d, and the fabric density of the skeleton material is 18×12 threads / inch.

[0034] In the hot-melt lamination, after preheating the base film and the facial mask, the base film is first bonded, and then the facial mask is bonded...

Embodiment 2

[0040] An anti-dialysis high-precision inkjet material prepared by the following method:

[0041] (1) Using high-strength and low-shrinkage polyester yarn as the raw material, the base fabric after warping, weaving and splitting and winding is used as the skeleton material; (2) The skeleton material in step (1) is dipped, dried and pre-shaped , using double-sided hot-melt lamination of PVC film and then embossing, cooling, shaping and trimming to obtain anti-dialysis high-precision inkjet materials. The preparation process of step (2) is as figure 1 As shown, 1 is the skeleton material, 2 is the base film, 3 is the mask, and 4 is the water-based polyurethane glue.

[0042] The specification of the high-strength and low-shrinkage polyester yarn is 500d, and the fabric density of the skeleton material is 18×18 threads / inch.

[0043] In the hot-melt lamination, after preheating the base film and the facial mask, the base film is first bonded, and then the facial mask is bonded....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com