Alkaline chemical cleaning agent for electrogalvanizing pretreatment

A cleaning agent, a technology for electro-galvanized sheet, applied in the field of cleaning agents, can solve problems such as unreported, and achieve the effects of wide applicability, wide operating temperature range and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A chemical cleaning agent for pretreatment of electro-galvanized sheets, the components and their mass percentages include: 35% sodium hydroxide, 40% sodium carbonate, 5% trisodium phosphate, 5% sodium benzoate, 9.5% sodium citrate, Nonylphenol polyoxyethylene ether surfactant 5%, polyether type defoamer 0.5%; weigh each raw material chemical cleaning agent according to the above ratio conditions, stir and mix the weighed raw materials evenly, and obtain the pretreatment of electro-galvanized sheet Use chemical cleaners.

[0033] The chemical cleaning agent obtained in this example is added with water to prepare a mixed solution with a total concentration of each component of 3%, which is used to chemically clean electrogalvanized sheets (cold-rolled sheets with a plate thickness of 0.5mm). The specific parameters are as follows: cleaning temperature The temperature is 80°C, the spray cleaning pressure is 0.5MPa, and the spray cleaning time is 10s.

[0034] During the ...

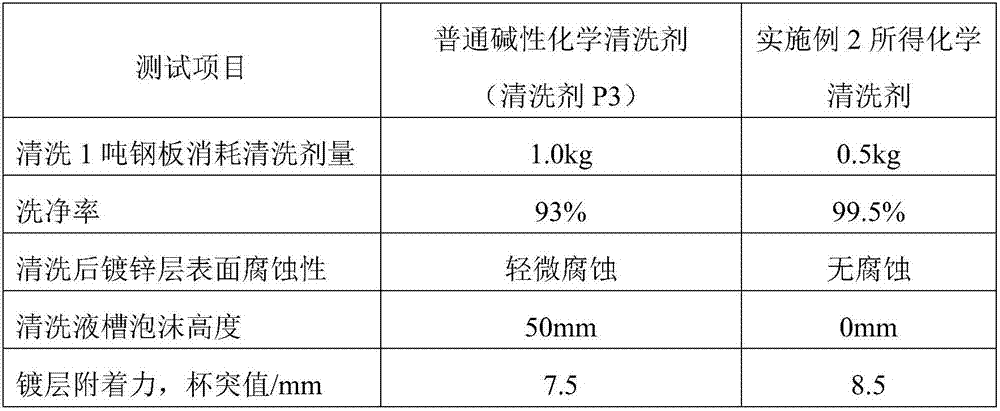

Embodiment 2

[0037] A chemical cleaning agent for pretreatment of electro-galvanized sheets, the components and their mass percentages include: 20% sodium hydroxide, 35% sodium carbonate, 15% trisodium phosphate, 10% sodium benzoate, 7% sodium citrate, Nonylphenol polyoxyethylene ether surfactant 11%, polyether type defoamer 2%; weigh each raw material chemical cleaning agent according to the above proportioning conditions, stir and mix the weighed raw materials evenly, and obtain the pretreatment of electro-galvanized sheet Use chemical cleaners.

[0038] The chemical cleaning agent obtained in this example is added with water to prepare a mixed solution with a total concentration of each component of 2.5%, which is used to chemically clean electrogalvanized sheets (cold-rolled sheets with a plate thickness of 0.8mm). The specific parameters are as follows: cleaning temperature The temperature is 70°C, the spray cleaning pressure is 0.25MPa, and the spray cleaning time is 5s.

[0039] Duri...

Embodiment 3

[0041] A chemical cleaning agent for pretreatment of electro-galvanized sheets, the components and their mass percentages include: 16% sodium hydroxide, 55% sodium carbonate, 6% trisodium phosphate, 6% sodium benzoate, 10% sodium citrate, Nonylphenol polyoxyethylene ether surfactant 6%, polyether type defoamer 1%; weigh each raw material chemical cleaning agent according to the above ratio conditions, stir and mix the weighed raw materials evenly to obtain the pretreatment of electro-galvanized sheet Use chemical cleaners.

[0042] The chemical cleaning agent obtained in this embodiment is added with water to prepare a mixed solution with a total concentration of each component of 2%, which is used to chemically clean electrogalvanized sheets (cold-rolled sheets with a plate thickness of 1.0mm). The specific parameters are as follows: cleaning temperature The temperature is 90°C, the spray cleaning pressure is 0.4MPa, and the spray cleaning time is 15s.

[0043] During the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com