Technical configuration method for major-diameter aluminum-alloy round cast ingot heating facility

A configuration method and heating facility technology, applied in the field of aluminum alloy processing, can solve the problems of large radial temperature difference, affecting product performance, long heating time, etc., and achieve the effect of solving large radial temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

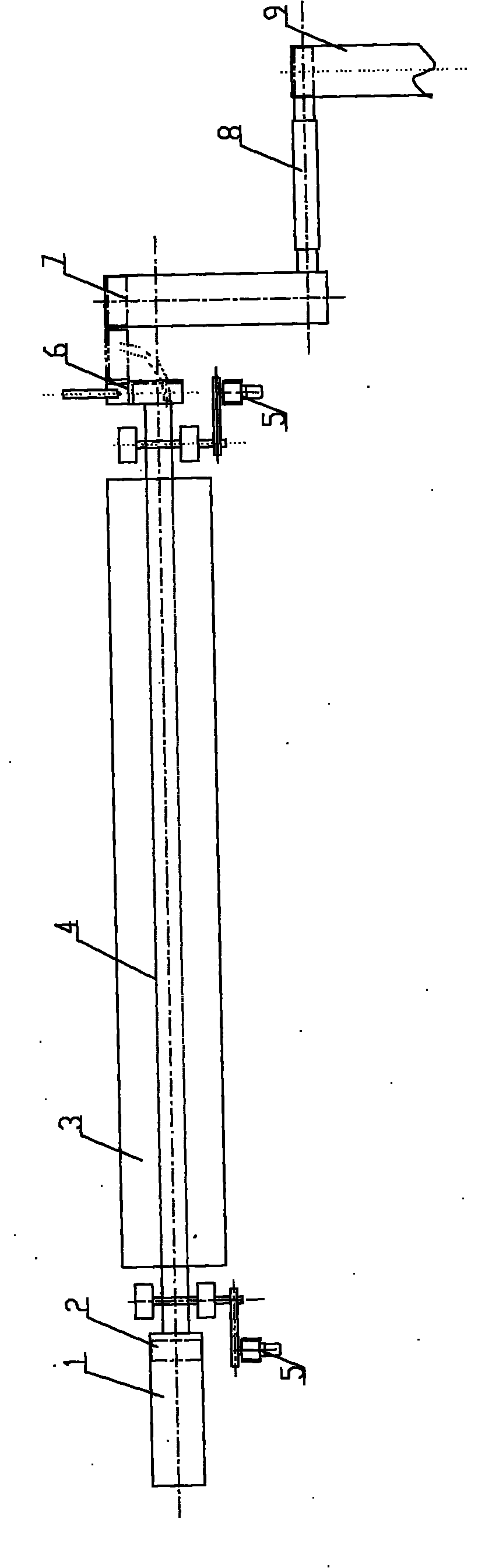

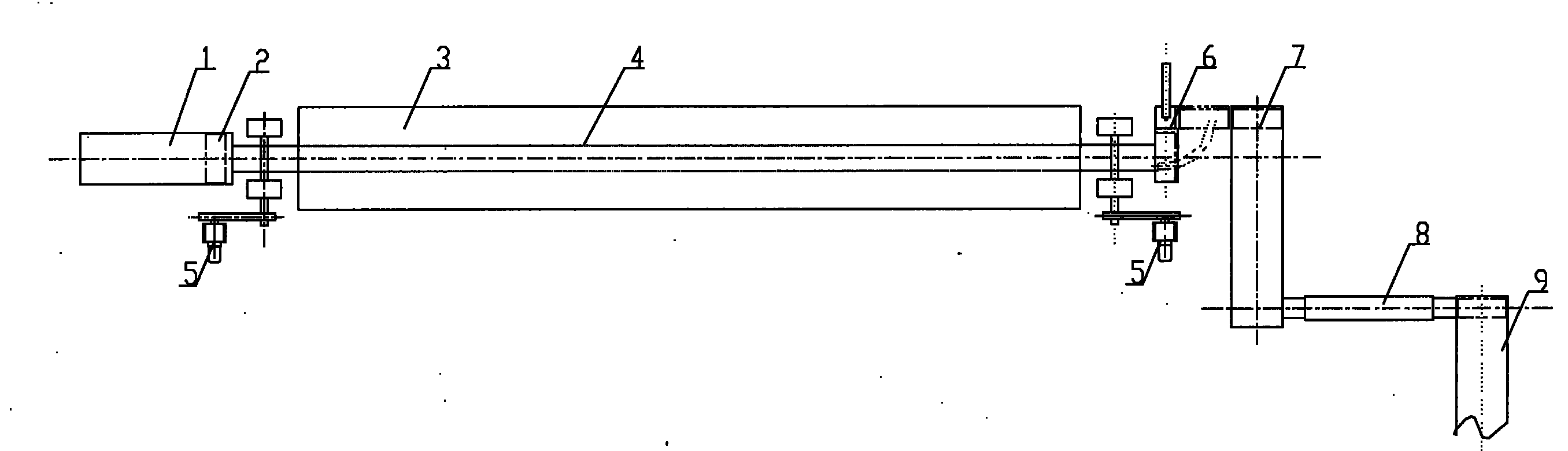

[0016] to combine figure 1 , the process configuration method of the large-diameter aluminum alloy round ingot heating facility of the present invention mainly includes two-step process configuration of preheating and gradient heating; preheating is to place the aluminum alloy round ingot on the feeding table and transport it through the chain and the chain The motor is transported to the natural gas preheating furnace for heating. The furnace temperature of the natural gas preheating furnace is controlled at 300-350°C. The walking speed is controlled by the chain conveying motor; the gradient heating is to move the aluminum alloy round ingot out of the natural gas preheating furnace through the rotary table for 90° rotation adjustment and then push it to the ingot transporting trolley, and the ingot transporting trolley will transfer the aluminum alloy round casting The ingot is transported to the induction heating furnace and then pushed into the induction heating furnace fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com