Steel tube online cooling process control system and method

A process control system and steel pipe technology, applied in temperature control, workpiece cooling device, metal rolling, etc., can solve problems such as single process, and achieve good performance and shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

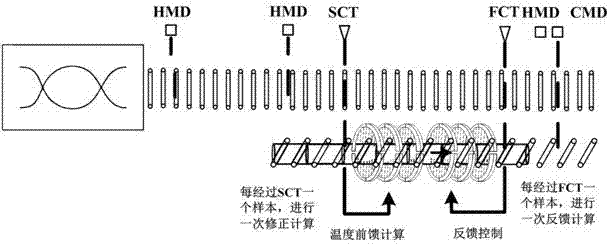

[0024] see figure 1 with Figure 5 , a process control system for on-line cooling of steel pipes (L2 for short), including:

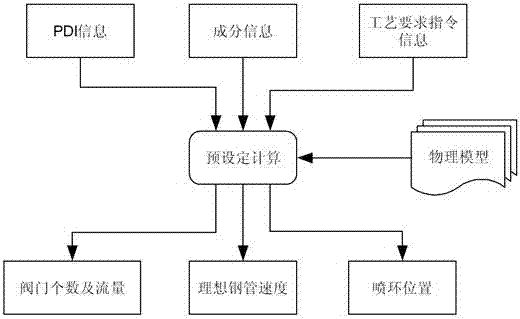

[0025] Presetting calculation module: when the steel pipe leaves the sizing machine, the hot metal detector HMD at the outlet of the sizing machine triggers the presetting calculation module; according to the original data of the steel pipe, the cooling target process data and the actual measurement data, the operation of the steel pipe head Set the speed curve, cooling spray ring configuration, cooling water pressure and flow rate, set the cooling speed curve of the steel pipe according to the temperature distribution of the steel pipe exiting the sizing machine, and the production rhythm, and transmit the setting results to the basic automation system for online cooling ( L1 for short), see figure 2 .

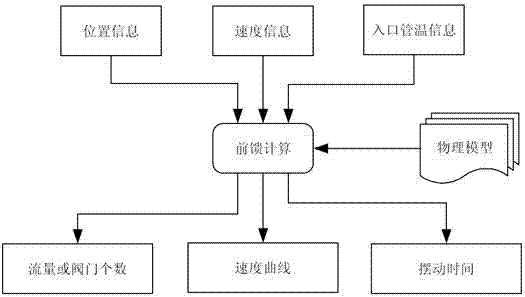

[0026] Fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com