Preparing method of high-performance multi-sized nanostructure skutterudite material

A nanostructure, multi-dimensional technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of reduced performance of bulk materials, decreased performance or activity, poor repeatability, etc., to achieve High thermoelectric figure of merit, good shape and performance, and high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

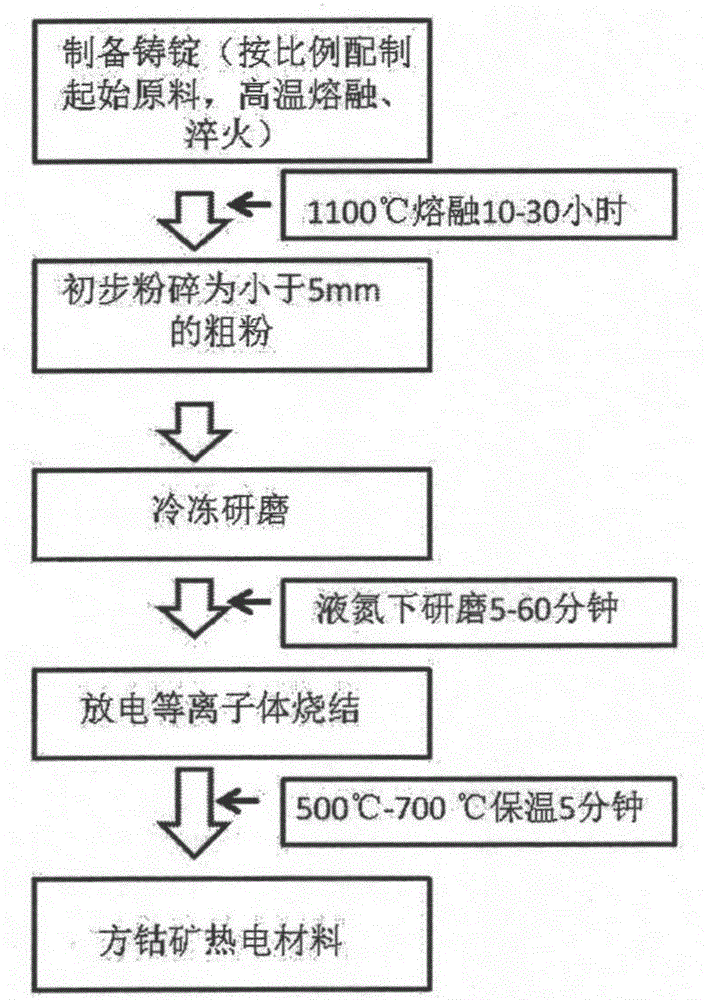

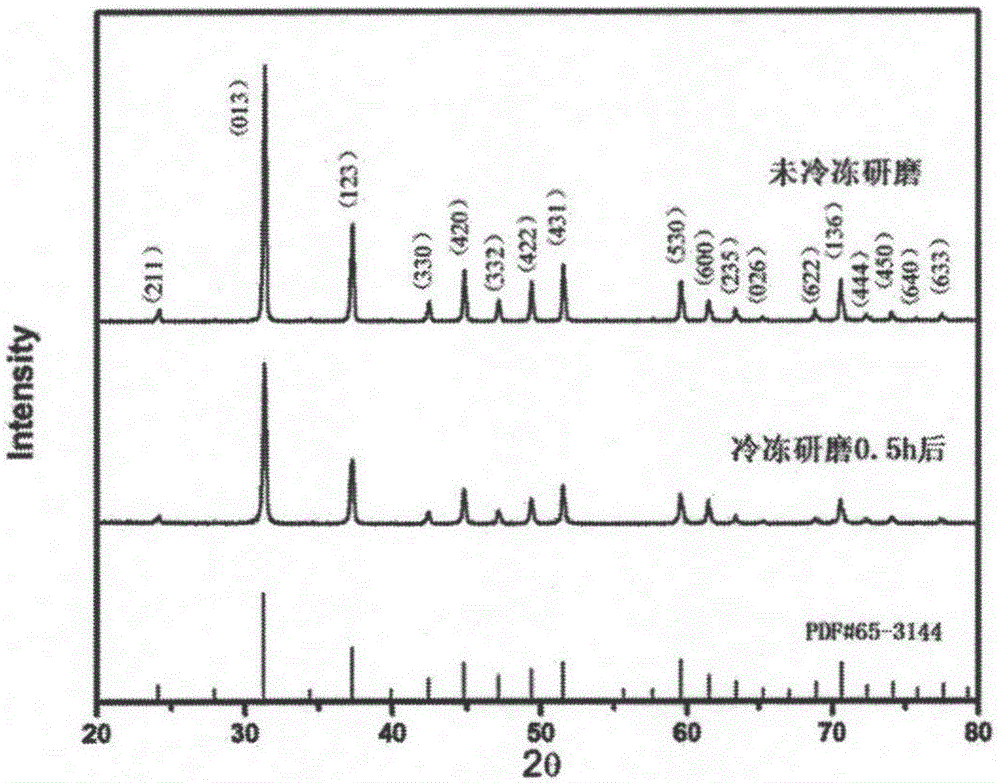

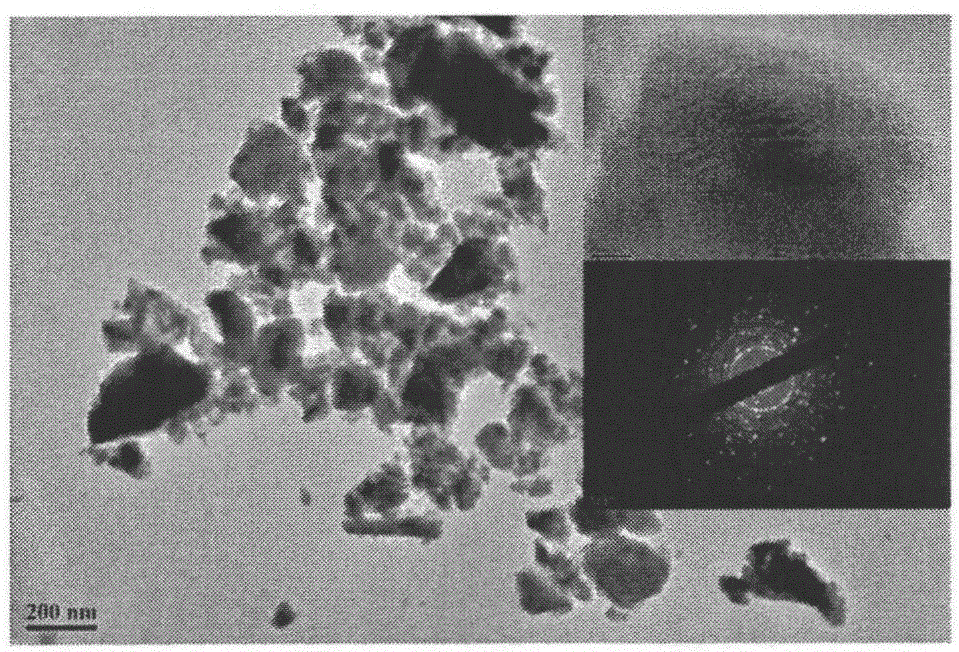

Embodiment 1

[0031] Homemade Yb by melting method 0.3 Co 4 Sb 12 Polycrystalline materials are used as raw materials, and nano-scale powders are prepared by freezing and grinding methods, and the thermoelectric material blocks are obtained by spark plasma sintering technology. The specific process flow is as follows figure 1 The specific steps are as follows: first crush the crystal material in a steel mold into coarse particles less than 5mm, weigh 20g of the sample and the stainless steel ram into the central cylinder, and then fix it on a freezing grinder filled with liquid nitrogen. Set the starting pre-cooling time to 20min, the frequency to 10cps, the single grinding time to 3min, the single cooling time to 3min, and the cycle to be 20. This not only guarantees the grinding, and at the same time, recooling can also bring out the heat generated by the grinding to avoid occurrence. Phase change or chemical decomposition. After 60 minutes of freezing and grinding, it was raised to room te...

Embodiment 2

[0033] Ba made by melting method 0.3 Co 4 Sb 12 The crystal material is the raw material. Firstly, the crystal material is crushed into coarse particles less than 5mm in a steel mold, and 15g of the sample is weighed into the central cylinder together with the stainless steel ram, and then fixed on a freezing grinder filled with liquid nitrogen. Set the starting pre-cooling time to 10min, the frequency to 7cps, the single grinding time to 2min, the single cooling time to 2min, and the cycle to be 60. This not only ensures the grinding, while re-cooling can also bring out the heat generated by the grinding to avoid occurrence Phase change or chemical decomposition. After 120 minutes of freezing and grinding, it was raised to room temperature and then sampled, and then vacuum-dried to obtain nano-sized powder. Put the powder into a graphite mold and put it into the SPS sintering furnace. Under the protection of argon-hydrogen mixture, the temperature is rapidly raised to 670°C an...

Embodiment 3

[0035] Yb made by melting method 0.2 In 0.1 Co 4 Sb 12 The crystal material is the raw material. First, the crystal material is crushed into coarse particles smaller than 5mm in a steel mold, and 15-20g of the sample is weighed into the central cylinder with the stainless steel ram, and then fixed on the freezing grinder filled with liquid nitrogen. Set the starting pre-cooling time to 15min, the frequency to 9cps, the single grinding time to 3min, the single cooling time to 3min, and the cycle to 50. This not only ensures the grinding, while re-cooling can also bring out the heat generated by the grinding to avoid occurrence Phase change or chemical decomposition. After 150 minutes of freezing and grinding, it was raised to room temperature and then sampled, and then vacuum-dried to obtain nano-sized powder. Put the powder into a graphite mold, put it into an SPS sintering furnace, and quickly raise the temperature to 600°C under an Ar gas shield and keep it at 65MPa for 3 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com