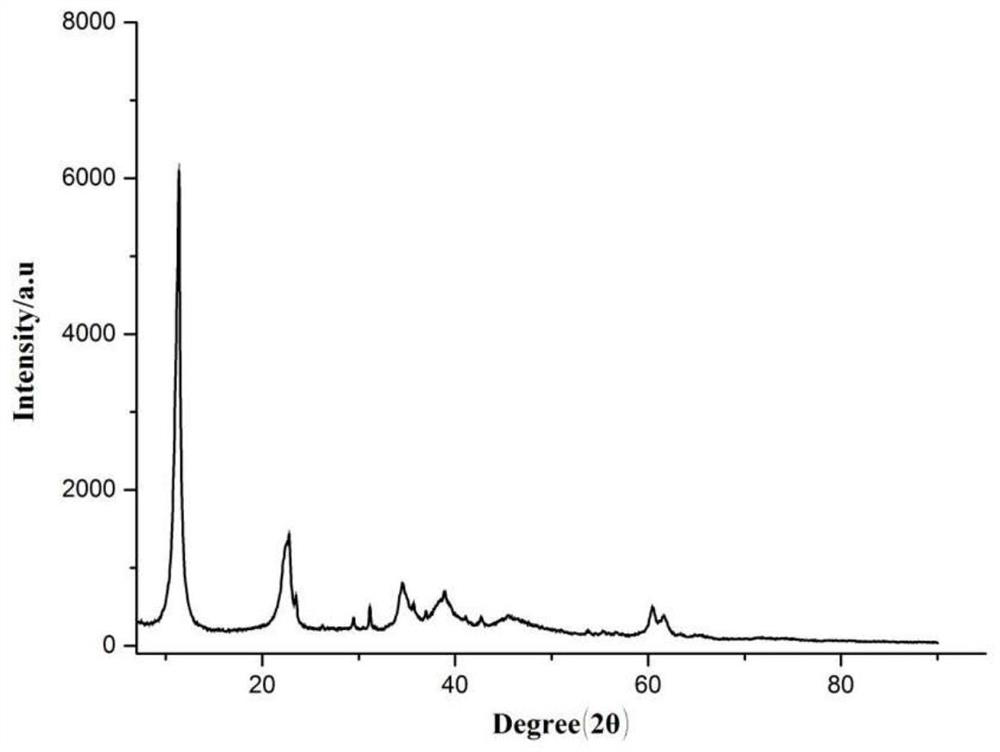

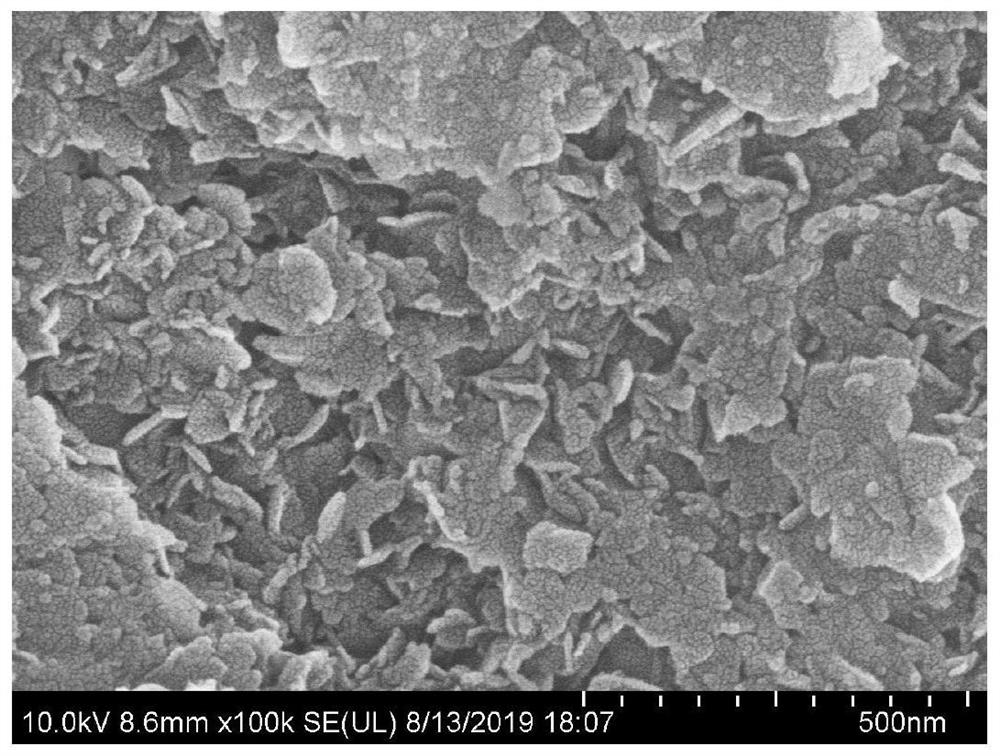

Method for preparing composite flame retardant of organic acid pillared hydrotalcite using phosphorus tailings

A technology of composite flame retardant and organic acid column, which is applied in the field of waste resource utilization, can solve the problems of low resource utilization rate of phosphorus tailings and low added value of products, and achieve reduction of preparation costs, huge economy, and improvement of ecology environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing a composite flame retardant of organic acid pillared hydrotalcite by utilizing phosphorus tailings, specifically comprising the following steps:

[0032] 1) Weigh 100g of phosphorus tailings, wash them repeatedly, dry them, place them in a muffle furnace and calcinate them at 600°C for 3 hours, remove organic impurities, and obtain impurity-removed phosphorus tailings;

[0033] 2) Add 80ml of hydrochloric acid into the stirring reactor, start stirring, raise the temperature to 50°C, slowly add the phosphorus tailings that have been removed in step 1), stir and react for 2.5 hours, after the leaching reaction is fully carried out, heat-preserve and filter, and then , add white clay to the above-mentioned filtrate by the dosage of 20g / L, stir, filter, obtain refined inorganic acid decomposition filtrate A;

[0034] 3) Add the inorganic acid decomposition filtrate A in step 2) into a three-necked flask, stir and dropwise add ammonia water with a mass...

Embodiment 2

[0038] A method for preparing a composite flame retardant of organic acid pillared hydrotalcite by utilizing phosphorus tailings, specifically comprising the following steps:

[0039] 1) Weigh 100g of phosphorus tailings, wash them repeatedly, then dry them, place them in a muffle furnace and calcinate at 700°C for 2 hours, remove organic impurities, and obtain impurity-removed phosphorus tailings;

[0040] 2) Add 70ml of hydrochloric acid into the stirred reactor, start stirring, heat up to 60°C, slowly add the phosphorus tailings that have been removed in step 1), stir and react for 2 hours, after the leaching reaction is fully carried out, heat-preserve and filter, and then , add clay to the above-mentioned filtrate according to the dosage of 30g / L, stir, filter, obtain refined inorganic acid decomposition filtrate A;

[0041] 3) Add the inorganic acid decomposition filtrate A in step 2) into a three-necked flask, stir and dropwise add ammonia water with a mass fraction of ...

Embodiment 3

[0045] A method for preparing a composite flame retardant of organic acid pillared hydrotalcite by utilizing phosphorus tailings, specifically comprising the following steps:

[0046] 1) Weigh 100g of phosphorous tailings, wash them repeatedly, then dry them, place them in a muffle furnace and calcinate them at 800°C for 1 hour, remove organic impurities, and obtain impurity-removed phosphorous tailings;

[0047] 2) Add 77ml of hydrochloric acid into the stirred reactor, start stirring, raise the temperature to 70°C, slowly add the phosphorus tailings that have been removed in step 1), stir and react for 1.5 hours, after the leaching reaction is fully carried out, heat-preserve and filter, and then , add white clay to the above-mentioned filtrate by the dosage of 40g / L, stir, filter, obtain refined inorganic acid decomposition filtrate A;

[0048] 3) Add the inorganic acid decomposition filtrate A in step 2) into a three-necked flask, stir and dropwise add ammonia water with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com