A kind of preparation method of electric field activated supercapacitor

A supercapacitor, electric field activation technology, applied in the manufacture of hybrid/electric double layer capacitors, etc., can solve the problems of large ionic radius, large volume of non-closed structure quaternary ammonium salt, poor chemical stability of non-closed structure quaternary ammonium salt, etc. The effect of high electric field activation voltage and working voltage, improving constant current charging and discharging efficiency, and improving insertion-migration capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

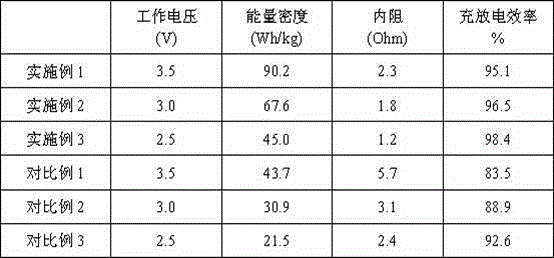

Examples

Embodiment 1

[0022] 1. The specific surface area of 100gBET is 50m 2 / g, layer spacing (d 002 ) is mesophase carbon microspheres of 0.355nm, 5g of polytetrafluoroethylene powder is used as binder, 1g of Ketjen black is used as conductive agent, 15g of isopropanol is added, mixed in a planetary ball mill for 48 hours, and then mixed in a jet mill Crushed into particles with a particle size of less than 100 μm, press the single-sided coating with a thickness of 100 μm and 500 μm on two pieces of stainless steel foil by a roller press, and then use a button cell slicer to cut into pieces Φ A 15.5mm disc was vacuum-dried at 180°C for 24 hours to obtain an electrode sheet;

[0023] 2. Use the electrode sheet with a coating thickness of 100 μm as the positive electrode, and the electrode sheet with a coating thickness of 500 μm as the negative electrode. In an argon atmosphere glove box (water, oxygen content ≤ 10ppm), the positive electrode and the negative electrode are separated by a poly...

Embodiment 2

[0026] 1. The specific surface area of 100gBET is 200m 2 / g, layer spacing (d 002 ) is 0.375nm expanded graphite, 10g polyvinylidene fluoride powder is used as binder, 5g synthetic graphite is used as conductive agent, 50g dimethylformamide is added, mixed in a high-speed mixer for 24h, and two pieces of copper are coated with a spreader After the surface of the foil is coated with a coating with a thickness of 50 μm and 200 μm, it is vacuum-dried at 150 ° C for 48 hours to prepare an electrode sheet;

[0027] 2. The electrode sheet with a coating thickness of 50 μm is used as the positive electrode, and the electrode sheet with a coating thickness of 200 μm is used as the negative electrode. The pole piece of cm was prepared into a coiled electrode, and dried in vacuum at 150°C for 24 hours; in an argon atmosphere glove box (water and oxygen content ≤ 10ppm), the dried coiled electrode was packaged in a stainless steel battery case, and added Tetrabutylammonium trifluoros...

Embodiment 3

[0030] 1. The specific surface area of 100gBET is 500m 2 / g, layer spacing (d 002 ) is 0.385nm pyrolytic graphite, 15g styrene-butadiene rubber and 35g sodium carboxymethyl cellulose are binders, 50g natural flake graphite is a conductive agent, add 60g deionized water, mix in a homogenizer for 12h, and use a coating After coating the surface of the corroded aluminum foil with a thickness of 100 μm, it was vacuum-dried at 80° C. for 48 hours to prepare electrode sheets.

[0031] 2. Cut the prepared electrode sheet into two rectangular sheets of 2.0cm×10.0cm as the positive electrode and the negative electrode of the electrode respectively, and separate the positive electrode and the negative electrode with a glass fiber separator, and use a pole piece winding machine to prepare a winding The electrode was vacuum-dried at 120°C for 24 hours; in an argon atmosphere glove box (water and oxygen content ≤ 10ppm), the dried wound electrode was packaged in a stainless steel batter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com