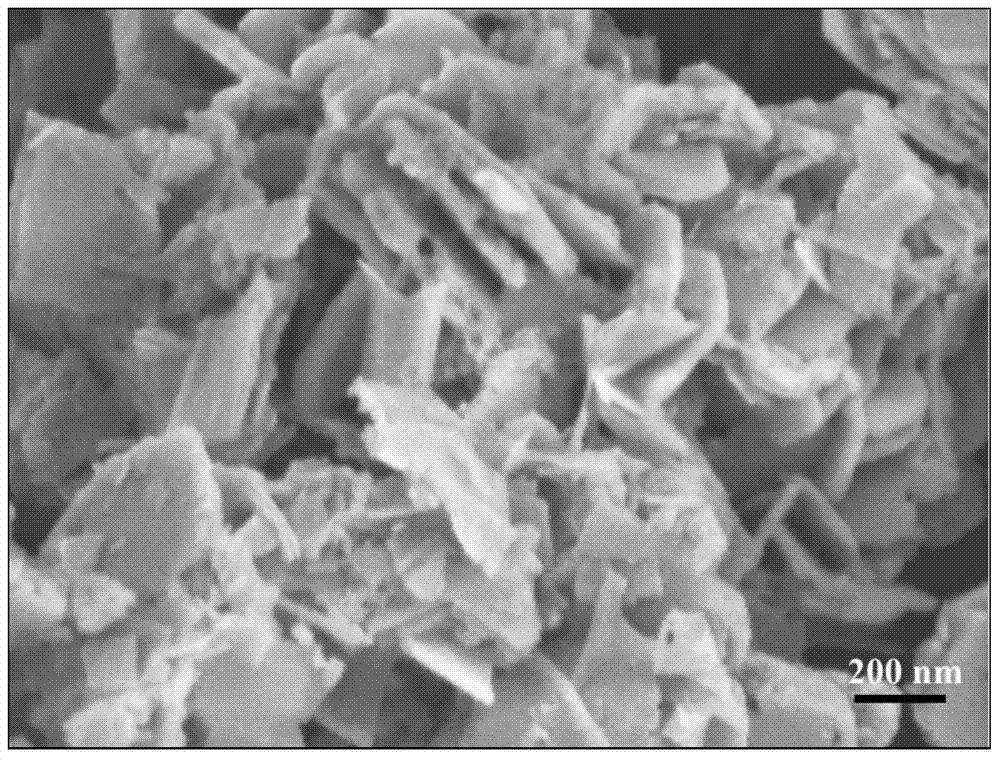

A kind of layered structure copper-based catalyst and its preparation method and application

A copper-based catalyst, layered structure technology, applied in the preparation of hydroxyl compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of poor methanol selectivity, large specific surface area, low conversion rate, etc., and achieve stable reaction performance. , The effect of high catalytic activity and reduction of copper loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

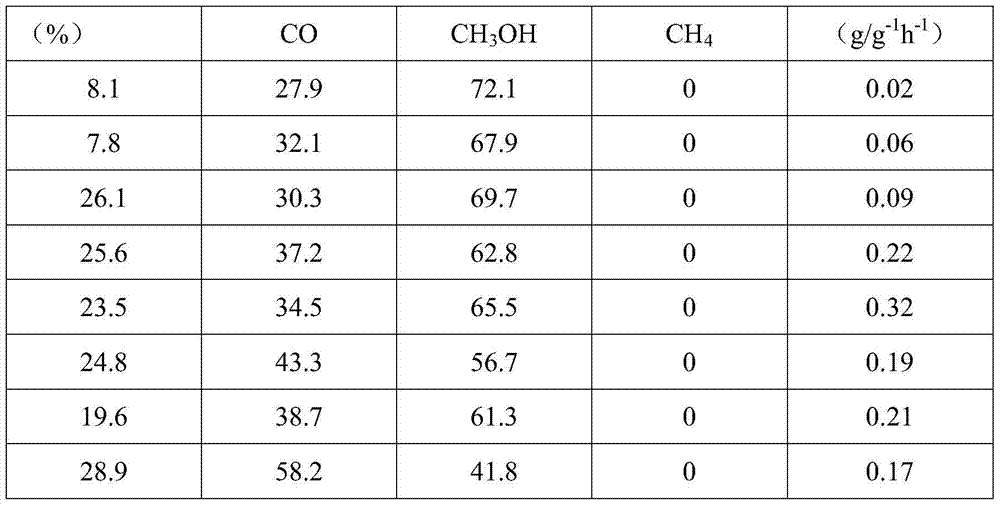

Embodiment 1

[0037] Take an appropriate amount of copper nitrate, zinc nitrate, aluminum nitrate, of which Cu 2+ , Zn 2+ and Al 3+ The ratio of the metal is based on the metal, and the molar ratio of various metals is: [n(Cu)+n(Zn)] / n(Al)=2, n(Cu) / n(Zn)=0.5, formulated as total metal ions The concentration of the mixed aqueous solution is 0.5mol / L, the mixed aqueous solution is heated to 80°C, the urea solution is added dropwise to the mixed aqueous solution through a peristaltic pump, and the speed of the peristaltic pump is 45r / min, wherein the concentration of the urea solution is urea: ∑M + =1:1(∑M + is the sum of the total metal ion concentration). During the dropwise addition process, an appropriate amount of nitrogen gas was continuously introduced, and the nitrogen flow rate was controlled by a mass flow meter, and the flow rate was 5 mL / min. Reflux for 6 hours, cool the precipitate, filter, wash, and dry (the drying temperature is 80°C, the drying time is 12h), and then roaste...

Embodiment 2

[0039] Take an appropriate amount of copper nitrate, zinc nitrate, aluminum nitrate, of which Cu 2+ , Zn 2+ and Al 3+ The ratio of the metal is based on the metal, and the molar ratio of various metals is: [n(Cu)+n(Zn)] / n(Al)=4, n(Cu) / n(Zn)=3, formulated as a total metal ion Concentration of 2.0mol / L mixed aqueous solution, heat the mixed aqueous solution to 80°C, urea solution is added dropwise to the mixed aqueous solution through a peristaltic pump, the speed of the peristaltic pump is 80r / min, and the concentration of the urea solution is urea: ∑M + =2.5:1(∑M + is the sum of the total metal ion concentration). During the dropwise addition, an appropriate amount of nitrogen gas was continuously introduced, and the nitrogen flow rate was controlled by a mass flow meter, and the flow rate was 20 mL / min. Reflux for 12 hours, cool the precipitate, filter, wash, and dry (the drying temperature is 100°C, the drying time is 24h), and then roasted at 350°C for 3 hours to obtain...

Embodiment 3

[0041] Take an appropriate amount of copper nitrate, zinc nitrate, aluminum nitrate, of which Cu 2+ , Zn 2+ and Al 3+ The proportion of the metal is calculated, and the molar ratio of various metals is: [n(Cu)+n(Zn)] / n(Al)=6, n(Cu) / n(Zn)=1.5, and the total metal ion is prepared The concentration of the mixed aqueous solution is 3.0mol / L, the mixed aqueous solution is heated to 110°C, the urea solution is added dropwise into the mixed aqueous solution through a peristaltic pump, and the speed of the peristaltic pump is 70r / min, wherein the concentration of the urea solution is urea: ∑M + =6:1(∑M + is the sum of the total metal ion concentration). During the dropwise addition, an appropriate amount of nitrogen gas was continuously introduced, and the nitrogen flow rate was controlled by a mass flow meter, and the flow rate was 8 mL / min. Reflux for 48 hours, cool the precipitate, filter, wash, and dry (the drying temperature is 100°C, the drying time is 24h), and then roasted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com