A kind of ternary cathode material for NCF type thermal battery and preparation method thereof

A cathode material and thermal battery technology, applied in the field of material chemistry, can solve the problems of no obvious improvement in performance and reports have not yet appeared, and achieve the effects of single component, improved cathode utilization rate, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

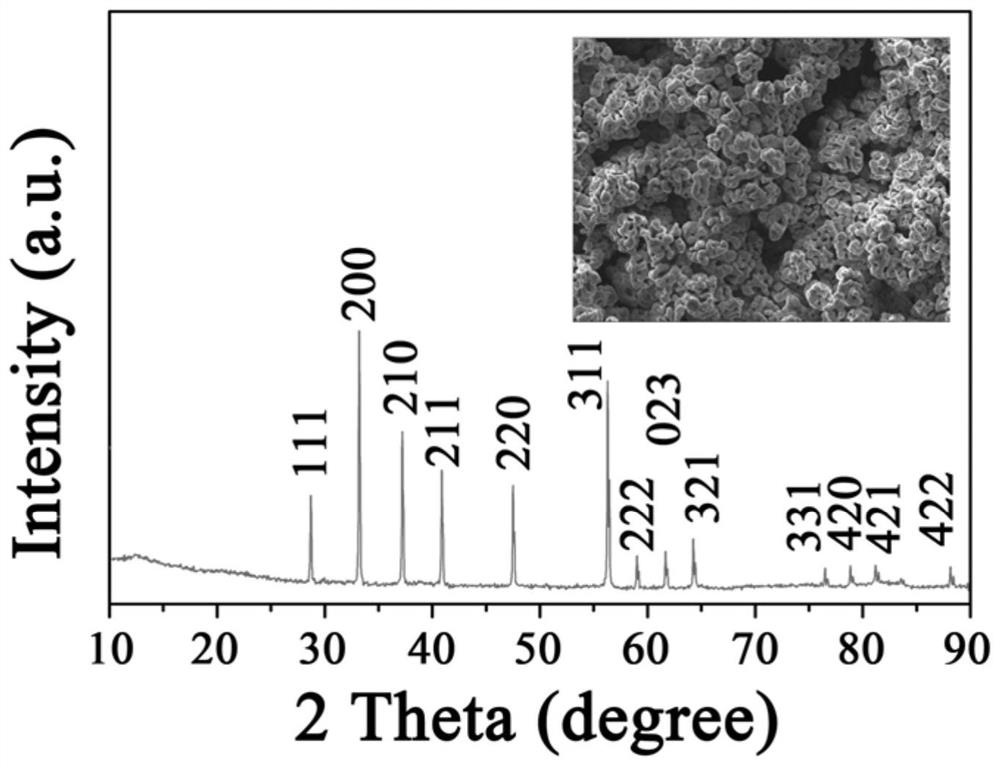

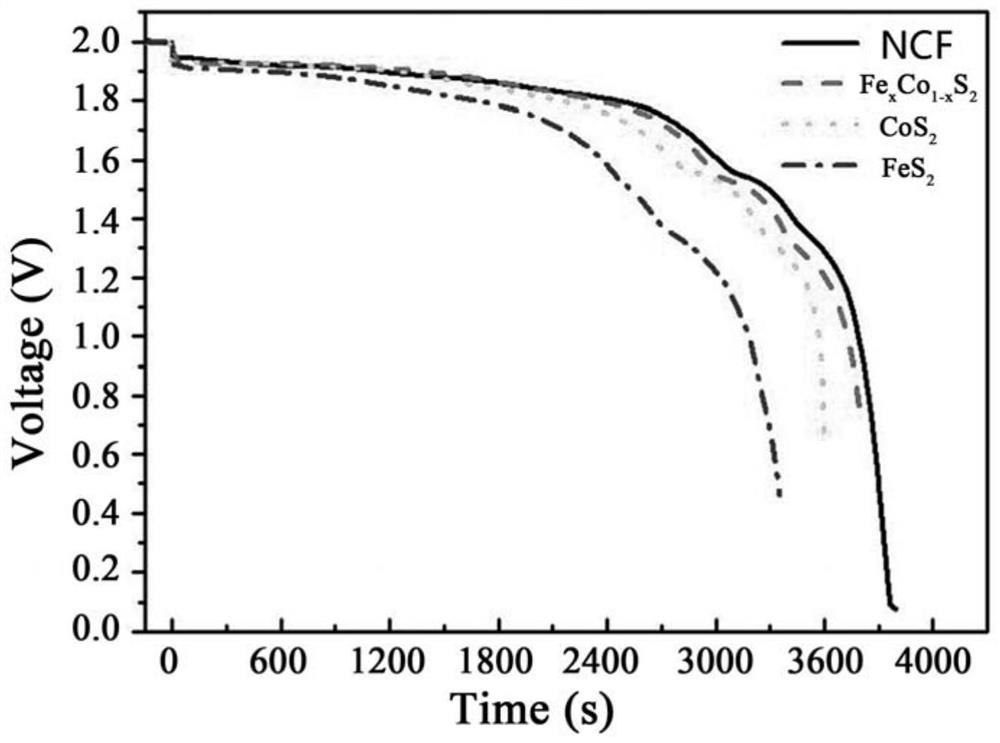

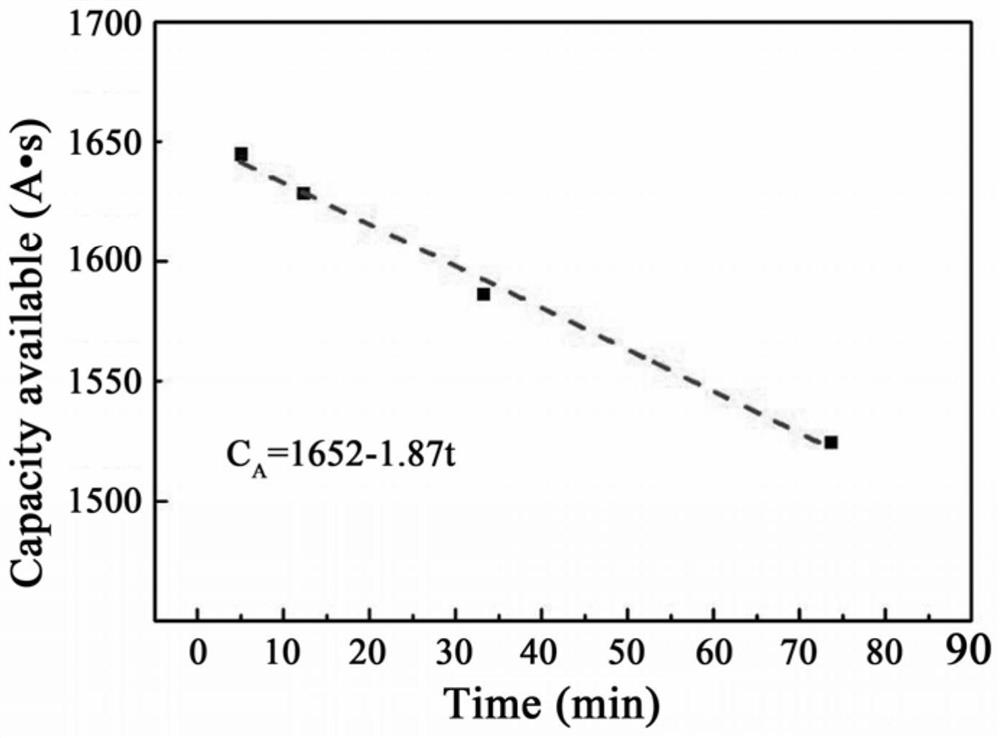

[0035] The weight ratio of target product NCF type ternary positive electrode material component for heat battery is: Ni 0.1 co 0.45 Fe 0.45 S 2 Accounted for 80%, Li 2O accounts for 5%, and the LiF-LiCl-LiBr electrolyte accounts for 15%. First, weigh NiSO according to the stoichiometric ratio 4 ·6H 2 O. CoSO 4 ·7H 2 O and FeSO 4 ·7H 2 O, configured as a solution with a total metal ion content of 1mol / L; slowly add 0.5mol / L (NH 4 ) 2 C 2 o 4 Solution to pH 12, stirred and aged for 2 hours, aged at room temperature, filtered, washed and dried to obtain the precursor, the drying temperature was 80°C; Reduction in the atmosphere, the reduction temperature is 600 ° C, the reduction time is 12 hours, after the reduction is completed, cool to room temperature and reheat to 120 ° C, and keep warm for 12 hours for passivation treatment; then put the metal powder in the atmosphere protection furnace, add excess Sulfur powder, carry out solid-phase reaction in an argon atm...

Embodiment 2

[0041] The weight ratio of target product NCF type ternary positive electrode material component for heat battery is: Ni 0.1 co 0.45 Fe 0.45 S 2 Accounted for 80%, Li 2 O accounts for 5%, and the LiF-LiCl-LiBr electrolyte accounts for 15%. First, weigh NiSO according to the stoichiometric ratio 4 ·6H 2 O. CoSO 4 ·7H 2 O and FeSO 4 ·7H 2 O, configured as a solution with a total metal ion content of 2mol / L; slowly add 0.5mol / L (NH 4 ) 2 C 2 o 4 Solution until the pH value is 13, stir and age for 12 hours, the aging temperature is 50 ° C, filter, wash the precursor and dry to obtain the precursor, the drying temperature is 120 ° C; the precursor is placed in a tubular reduction furnace, in Reduction in a hydrogen atmosphere, the reduction temperature is 700°C, and the reduction time is 6h. After the reduction is completed, cool to room temperature and reheat to 200°C, and keep warm for 6h for passivation treatment; then put the metal powder in the atmosphere protecti...

Embodiment 3

[0043] The weight ratio of target product NCF type ternary positive electrode material component for heat battery is: Ni 0.1 co 0.45 Fe 0.45 S 2 Accounted for 80%, Li 2 O accounts for 5%, and the LiF-LiCl-LiBr electrolyte accounts for 15%. First, weigh NiSO according to the stoichiometric ratio 4 ·6H 2 O. CoSO 4 ·7H 2 O and FeSO 4 ·7H 2 O, configured as a solution with a total metal ion content of 1mol / L; slowly add 0.5mol / L (NH 4 ) 2 C 2 o 4 Solution to pH 12, stirred and aged for 6 hours, aged at room temperature, filtered, washed and dried to obtain the precursor, the drying temperature was 110°C; the precursor was placed in a tubular reduction furnace, under hydrogen Reduction in the atmosphere, the reduction temperature is 650 ° C, the reduction time is 8 hours, after the reduction is completed, cool to room temperature and then reheat to 150 ° C, and keep warm for 8 hours for passivation treatment; then put the metal powder in the atmosphere protection furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com