Intermediate-temperate zinc phosphating solution and preparation method thereof

A zinc-based phosphating solution and medium-temperature technology, applied in the direction of metal material coating technology, can solve the problems of difficult process control, safety, environmental protection, economy and cheapness, and many raw materials for formula selection, so as to shorten the phosphating time, the process is concise, and the The effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

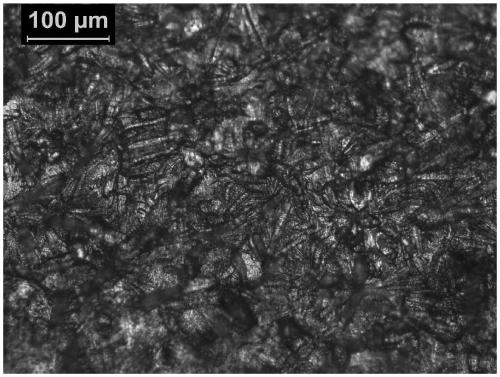

Image

Examples

Embodiment 1

[0019] A kind of preparation method of medium-temperature zinc system phosphating solution, it is that earlier by the zinc oxide 10% of proportioning by mass percentage, drop into the container that is filled with water and is equipped with stirrer such as reactor and stir 10min, the rotating speed of stirrer is 100rpm, then sequentially add 11.5% nitric acid and 22% phosphoric acid according to the mass percentage ratio in the aforementioned container and continue to stir for 30min, the rotating speed of the stirring device when continuing to stir is 80rpm, then add successively into the aforementioned container according to the mass percentage ratio Manganese nitrate 2%, sodium molybdate 1%, sodium gluconate 1% and sodium chlorate 0.1%, then stirred for 25min, then the rotating speed of the stirring device during stirring was controlled to 90rpm, after the completion of stirring, the solution was clear , so as to obtain a medium-temperature zinc-based phosphating solution. T...

Embodiment 2

[0021] A kind of preparation method of medium-temperature zinc system phosphating solution, it is to drop into the container that is filled with water and is equipped with stirrer such as reactor 20min with the zinc oxide 12% of proportioning by mass percentage earlier, and the rotating speed of stirrer is 20min. 90rpm, then sequentially add 10% nitric acid and 18% phosphoric acid according to the mass percentage ratio to the aforementioned container and continue to stir for 20min. Manganese nitrate 1.5%, sodium molybdate 0.7%, sodium gluconate 2.7% and sodium chlorate 0.6%, then stirred for 30min, then the rotating speed of the stirring device during stirring was controlled to be 80rpm, after finishing and then stirring, the solution was clear , so as to obtain a medium-temperature zinc-based phosphating solution. It can be seen that the water in the present embodiment is 54.5%.

Embodiment 3

[0023] A kind of preparation method of middle temperature zinc system phosphating solution, it is to drop into the container that is filled with water and is equipped with stirring device such as reactor and stir 15min by the zinc oxide 11% of proportioning by mass percentage earlier, the rotating speed of stirring device is 80rpm, then sequentially add 13% nitric acid and 15% phosphoric acid according to the mass percentage ratio in the aforementioned container and continue to stir for 25min. Manganese nitrate 1%, sodium molybdate 0.5%, sodium gluconate 1.4% and sodium chlorate 1%, then stirred for 20min, then the rotating speed of the stirring device during stirring was controlled to 100rpm, after the completion of stirring, the solution was clear , so as to obtain a medium-temperature zinc-based phosphating solution. This shows that the water in the present embodiment is 57.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com