Liquid surface regulator capable of improving film-forming performance of phosphating film and preparation method thereof

A technology of liquid surface and film-forming performance, applied in the direction of metal material coating process, etc., can solve the problems of difficult formation of phosphating film, rapid decline of phosphating tank, difficult storage of titanium colloid, etc. Phosphating temperature and effect of shortening phosphating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

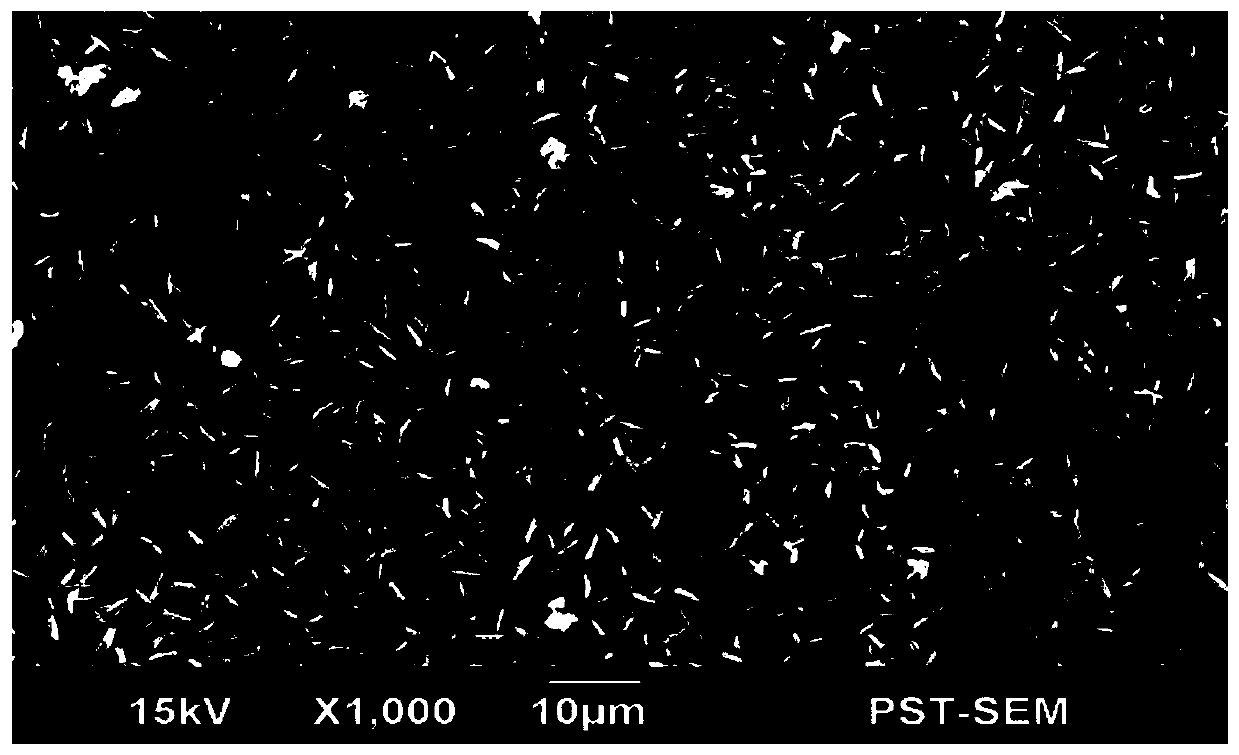

Image

Examples

Embodiment 1

[0026] The present invention can improve the preparation method of the liquid surface conditioner of phosphating film film-forming performance, first dissolve 3% zinc nitrate and 1% calcium nitrate in 25% water, then dissolve 8% disodium hydrogen phosphate in 15% % water, then mix the two solutions, then add 2% polyvinyl alcohol, stir well to get the colloidal active ingredient, then add 3% fatty alcohol polyoxyethylene ether sodium sulfate and 2% coke to the colloidal salt Trisodium phosphate is finally added with 41% water to form a uniform mixture, which is the liquid surface conditioner of the present invention; during the synthesis process, all operations are at normal temperature and constant stirring is required.

[0027] The weight percent of each component of the above-mentioned liquid surface conditioner is: 3% of zinc nitrate, 1% of calcium nitrate, 8% of disodium hydrogen phosphate, 2% of polyvinyl alcohol, 3% of fatty alcohol polyoxyethylene ether sodium sulfate, t...

Embodiment 2

[0029] The present invention can improve the preparation method of the liquid surface conditioner of film-forming performance of phosphating film, first dissolve 9% zinc nitrate and 5% calcium nitrate in 15% water, then dissolve 15% disodium hydrogen phosphate in 10 % water, then mix the two solutions, then add 4% polyvinyl alcohol, stir well to get the colloidal active ingredient, then add 7% fatty alcohol polyoxyethylene ether sodium sulfate and 5% coke to the colloidal salt Trisodium phosphate is finally added with 30% water to form a homogeneous mixture, which is the liquid surface regulator of the present invention; during the synthesis process, all operations are at normal temperature and continuous stirring is required.

[0030] The weight percent of each component of the above-mentioned liquid surface conditioner is: zinc nitrate 9%, calcium nitrate 5%, disodium hydrogen phosphate 15%, polyvinyl alcohol 4%, fatty alcohol polyoxyethylene ether sodium sulfate 7%, pyrophos...

Embodiment 3

[0032] The present invention can improve the preparation method of the liquid surface conditioner of film-forming performance of phosphating film, first dissolve 6% zinc nitrate and 3% calcium nitrate in 10% water, then dissolve 12% disodium hydrogen phosphate in 20 % water, then mix the two solutions, then add 3% polyvinyl alcohol, stir well to get the colloidal active ingredient, then add 5% fatty alcohol polyoxyethylene ether sodium sulfate and 4% coke to the colloidal salt Trisodium phosphate is finally added with 37% water to form a uniform mixture, which is the liquid surface conditioner of the present invention; during the synthesis process, all operations are at normal temperature and constant stirring is required.

[0033] The weight percent of each component of the above-mentioned liquid surface conditioner is: zinc nitrate 6%, calcium nitrate 3%, disodium hydrogen phosphate 12%, polyvinyl alcohol 3%, fatty alcohol polyoxyethylene ether sodium sulfate 5%, pyrophosphat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com