Low-temperature phosphating solution containing chromic acid

A low-temperature phosphating and chromic acid technology, which is applied in the coating process of metal materials, can solve the problems of low working temperature, low working efficiency and high working temperature, and achieve the effect of low working temperature, high working efficiency and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

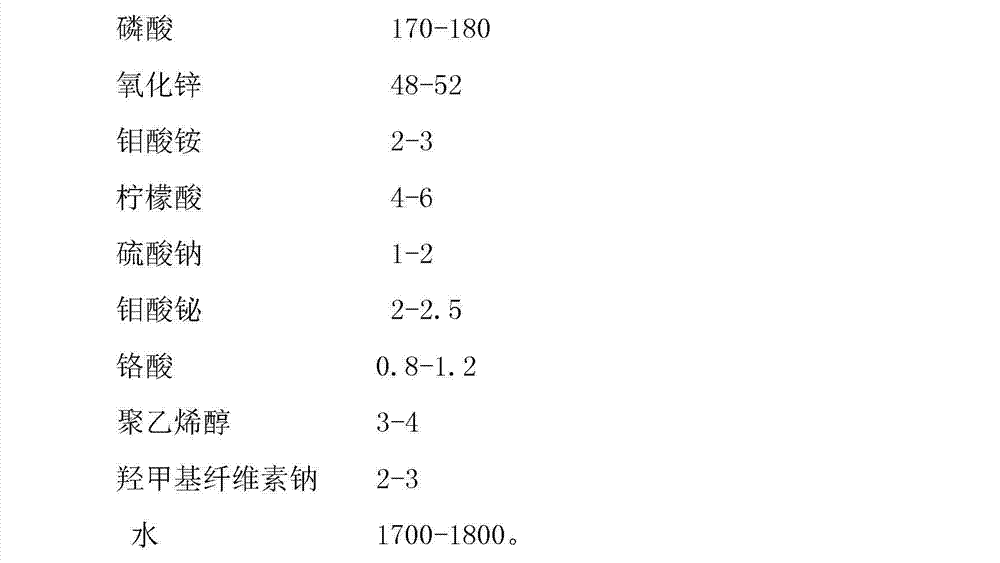

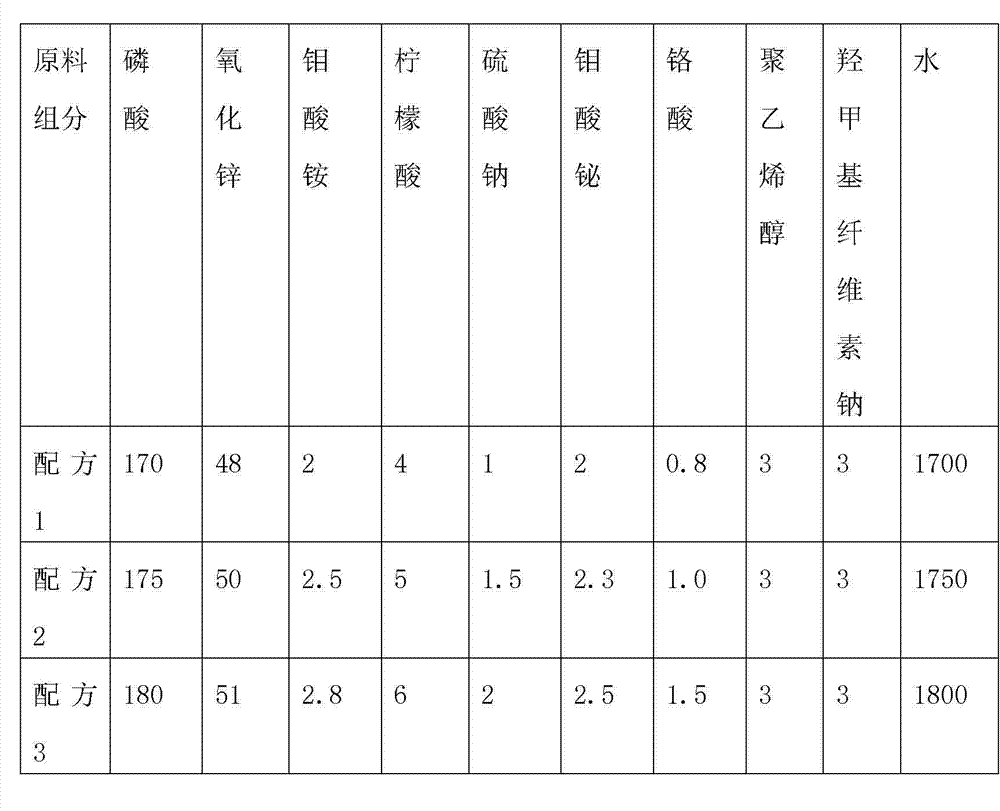

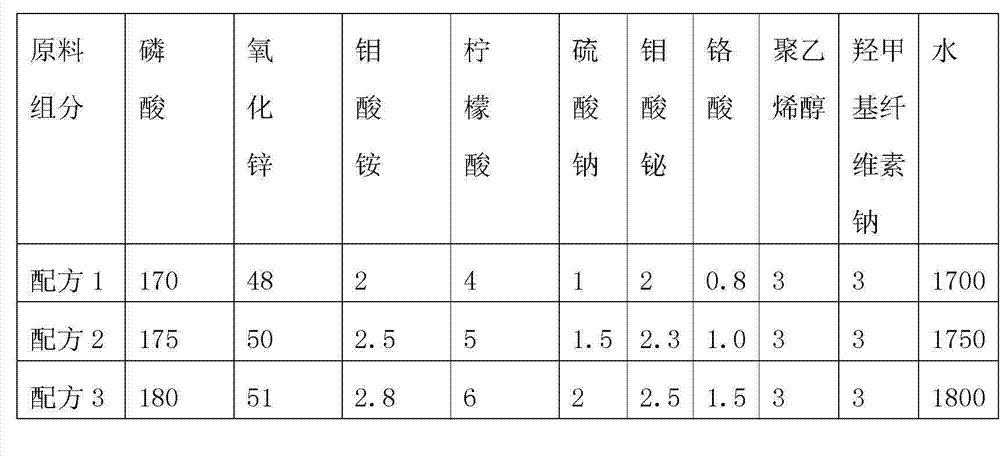

[0017] A low-temperature phosphating solution containing chromic acid, each raw material component is one of the formulas listed in the following table (g):

[0018]

[0019] .

[0020] The preparation method comprises the following steps:

[0021] (1) Dilute phosphoric acid at a ratio of 1:10, stir thoroughly, and place for 20-24 hours;

[0022] (2) Then add zinc oxide in the proportion of formula, stir thoroughly, and cool for 9-11 hours to obtain a mixture of phosphoric acid and zinc oxide;

[0023] (3) After fully mixing other ingredients in the formula, add it to the mixture in step (2), and stir well.

[0024] The following table is that the present invention and the characteristics of each index of traditional phosphating solution are compared as follows:

[0025] this invention

[0026] When working: Prepare the above-mentioned phosphating solution stock solution and water at a ratio of 1:25 to make a working solution, first pour water into the phospha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com