Production process of plastic coated pipe fitting without secondary tapping

A production process and technology of plastic pipe fittings, which is applied in the field of production process of plastic-coated composite pipe fittings, can solve problems such as high cost and high scrap rate, and achieve the effects of improving product quality, high production efficiency, and quality assurance of phosphating film

Active Publication Date: 2012-04-11

GUANGDONG LIANSU TECH INDAL

View PDF7 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In order to overcome the disadvantages of high scrap rate and high cost caused by the secondary tapping of the product tooth pattern after plastic coating in the above-mentioned prior art process, the present invention provides a plastic-coated pipe fitting without secondary tapping. production process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0019] The present invention is a production process that does not require secondary tapping of plastic-coated pipe fittings, and its specific process flow is as follows:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

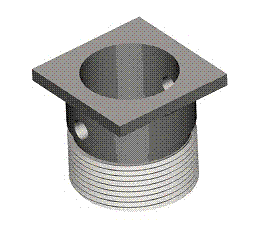

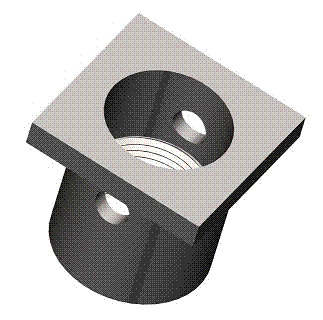

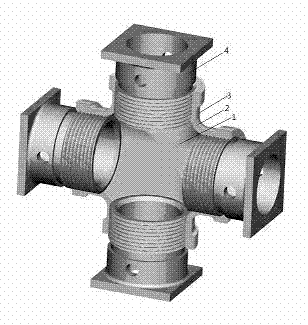

The invention provides a production process of a plastic coated pipe fitting without secondary tapping in order to overcome the defects of high rejection rate, high cost and the like, which are caused by secondary tapping on tooth patterns of a product after coating plastic in the prior art process. The production process comprises the following steps of: removing oil and rust from a malleable cast iron pipe fitting, neutralizing through swimming immersion, water washing through swimming immersion, surface conditioning through swimming immersion, high-temperature phosphating, water washing through swimming immersion, water washing through spraying, preheating, installing a tooth socket, coating plastic internally and externally, dismounting the tooth socket, curing and leveling, cooling, checking, preventing rust of the tooth patterns, and obtaining the finished product. Compared with the prior art, the production process has the beneficial effects that: due to the adoption of high-temperature Zn-Ca phosphating, the phosphating time is shortened, the quality of a phosphating film is ensured, the product has stable properties, such as adhesion force, impact property and the like, the production procedure is simple, the production efficiency is high, labor investment and high rejection rate caused by factors, such as secondary tapping and the like, are reduced, and the quality of the product is improved because a tooth pattern rust-preventing process is added.

Description

technical field [0001] The invention relates to a production process of plastic-coated composite pipe fittings, in particular to a production process of plastic-coated pipe fittings without secondary tapping. Background technique [0002] With the rapid development of national economic construction and the gradual improvement of urban infrastructure, people's living standards have been greatly improved. While my country's pipe processing industry is developing rapidly, problems related to sanitation, environmental protection, energy saving and emission reduction in processing and application links, as well as policy issues are becoming increasingly prominent. In 2000, the Ministry of Construction issued guidance documents for the selection of building materials in the construction field, clearly stipulating that galvanized steel pipes and various composite cast iron water supply pipes should be eliminated and restricted in construction projects. However, due to the disadvan...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16L9/147

Inventor 方有泉

Owner GUANGDONG LIANSU TECH INDAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com