Low temperature fast phosphating solution for drawing wire and its phosphating process

A phosphating solution and low-temperature technology, which is applied in the coating process of metal materials, etc., can solve the problems that the wire drawing production line cannot be subjected to medium-high temperature soaking and phosphating treatment, the lubricating performance between the wire rod and the mold is reduced, and the wire is broken during drawing. Achieve good effect, good environmental performance, and reduce usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

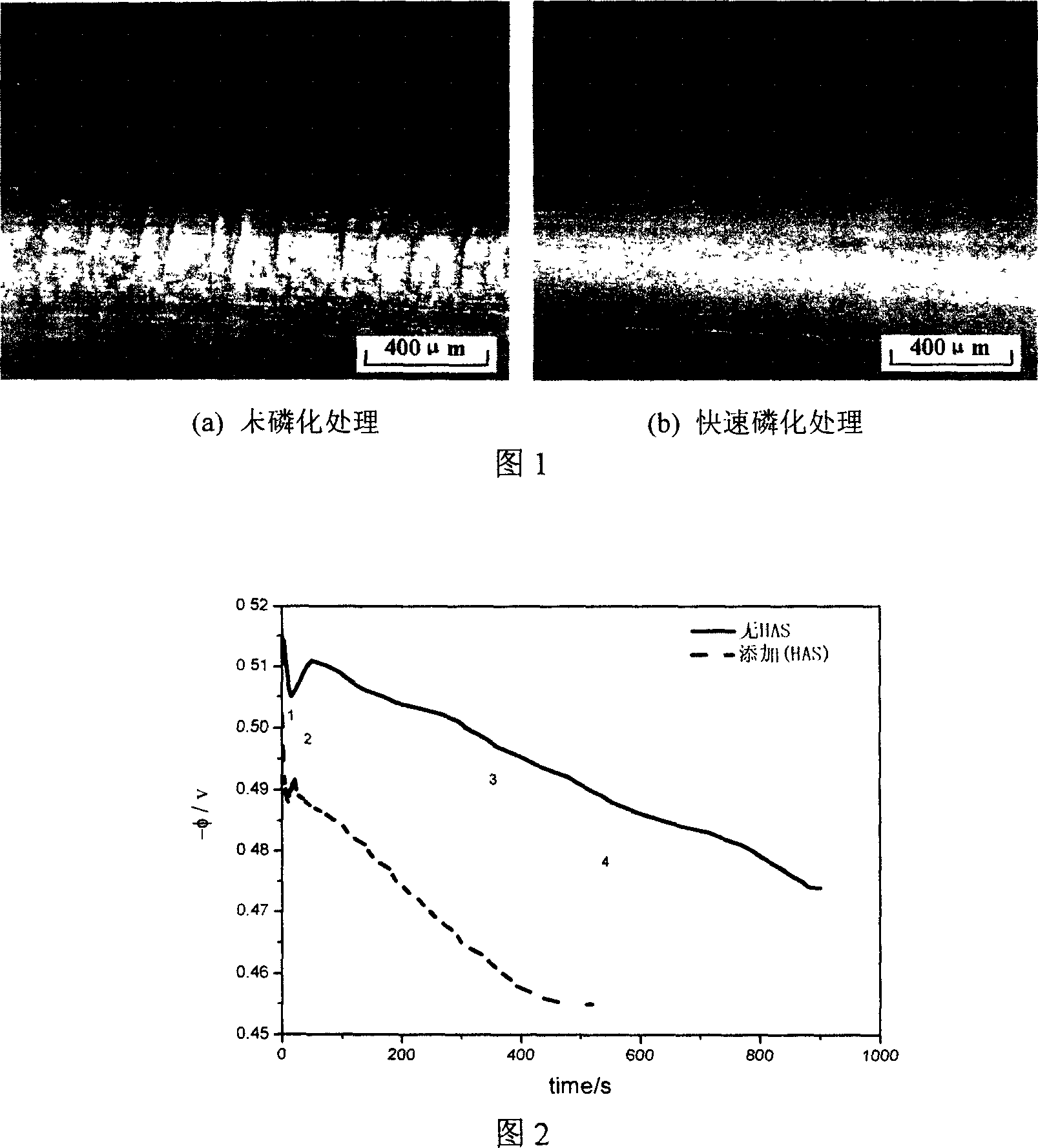

[0029] A low-temperature rapid phosphating solution for wire drawing, including Zn(H 2 PO 4 ) 2 , Zn(NO 3 ) 2 , H 3 PO 4 , HAS, La(NO 3 ) 3 and H 2 O, its mass ratio is: Zn(H 2 PO 4 ) 2 : Zn(NO 3 ) 2 :H 3 PO 4 :HAS:La(NO 3 ) 3 :H 2 O=65:60:8:5:0.5:861.5. It is used for phosphating of welding area of 1860MPa grade PC steel strand, the ambient temperature is 0°C, after phosphating for 7 minutes, the film weight after phosphating is 5g / m 2 , There is no transverse crack on the surface of the steel wire, and the broken wire caused by surface defects during the stranding process is basically eliminated.

Embodiment 2

[0031] A low-temperature rapid phosphating solution for wire drawing, including Zn(H 2 PO 4 ) 2 , Zn(NO 3 ) 2 , H 3 PO 4 , HAS, La(NO 3 ) 3 and H 2 O, its mass ratio is: Zn(H 2 PO 4 ) 2 : Zn(NO 3 ) 2 :H 3 PO 4 :HAS:La(NO 3 ) 3 :H 2 O=55:50:6:5:0.5:873.5. It is used for phosphating of welding area of 1860MPa grade PC steel strand, the ambient temperature is 5°C, after phosphating for 7 minutes, the film weight after phosphating is 5g / m 2 , There is no transverse crack on the surface of the steel wire, and the broken wire caused by surface defects during the stranding process is basically eliminated.

Embodiment 3

[0033] A low-temperature rapid phosphating solution for wire drawing, including Zn(H 2 PO 4 ) 2 , Zn(NO 3 ) 2 , H 3 PO 4 , HAS, La(NO 3 ) 3 and H 2 O, its mass ratio is: Zn(H 2 PO 4 ) 2 : Zn(NO 3 ) 2 :H 3 PO 4 :HAS:La(NO 3 ) 3 :H 2 O=50:50:5:6:0.5:888.5. It is used for phosphating of welding area of 1860MPa grade PC steel strand, the ambient temperature is 10°C, after phosphating for 7 minutes, the film weight after phosphating is 6g / m2 , There is no transverse crack on the surface of the steel wire, and the broken wire caused by surface defects during the stranding process is basically eliminated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com