Surface Treated Copper Foil for High Speed Printed Circuit Board Products Including the Copper Foil and Methods of Making

A surface treatment, high-speed printing technology, used in printed circuit manufacturing, printed circuits, printed circuit components, etc., can solve problems such as signal loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Roller polishing with buffing wheels

[0076] Roller speed: 1.0-5.0m / min

[0077] Polishing wheel speed: 150-550rpm (#1500, Nippon Tokushu Kento Co., Ltd.)

[0078] Load current: 0.5-1.5A

[0079] Preparation of electrolytic copper foil (untreated copper foil)

[0080] Copper wire was dissolved in 50% by weight of sulfuric acid aqueous solution to prepare 320g / L copper sulfate pentahydrate (CuSO 4 ·5H 2 O) and the copper sulfate electrolyte of 100g / L sulfuric acid. For each liter of copper sulfate electrolyte, 20 mg chloride ion, 0.35 mg gelatin (DV, Nippi Company) were added. Subsequently, at a liquid temperature of 50°C and 70A / dm 2 An electrolytic copper foil (untreated copper foil) with a thickness of 18 μm was prepared at a current density of 100 μm.

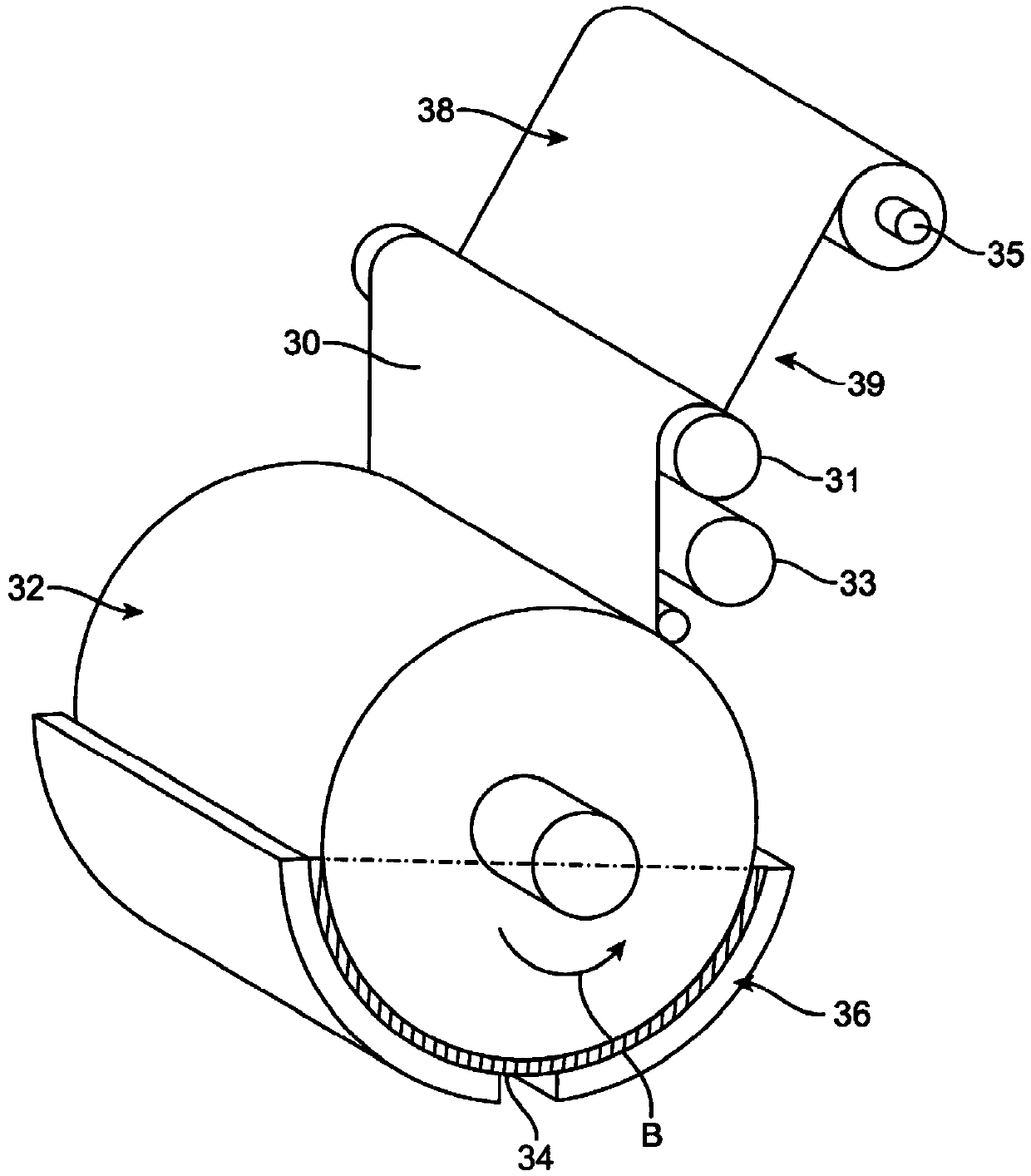

[0081] A typical apparatus for preparing electrolytic copper foil includes a metal cathode roll and an insoluble metal anode, generally as image 3 As shown, the metal cathode roll rotates about a central lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com