Preparation method for low alloy steel surface phosphating film

A surface phosphating and low-alloy steel technology, applied in phosphating, metal material coating process, etc., to achieve excellent corrosion resistance, simple pre-treatment process, and accelerated phosphating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

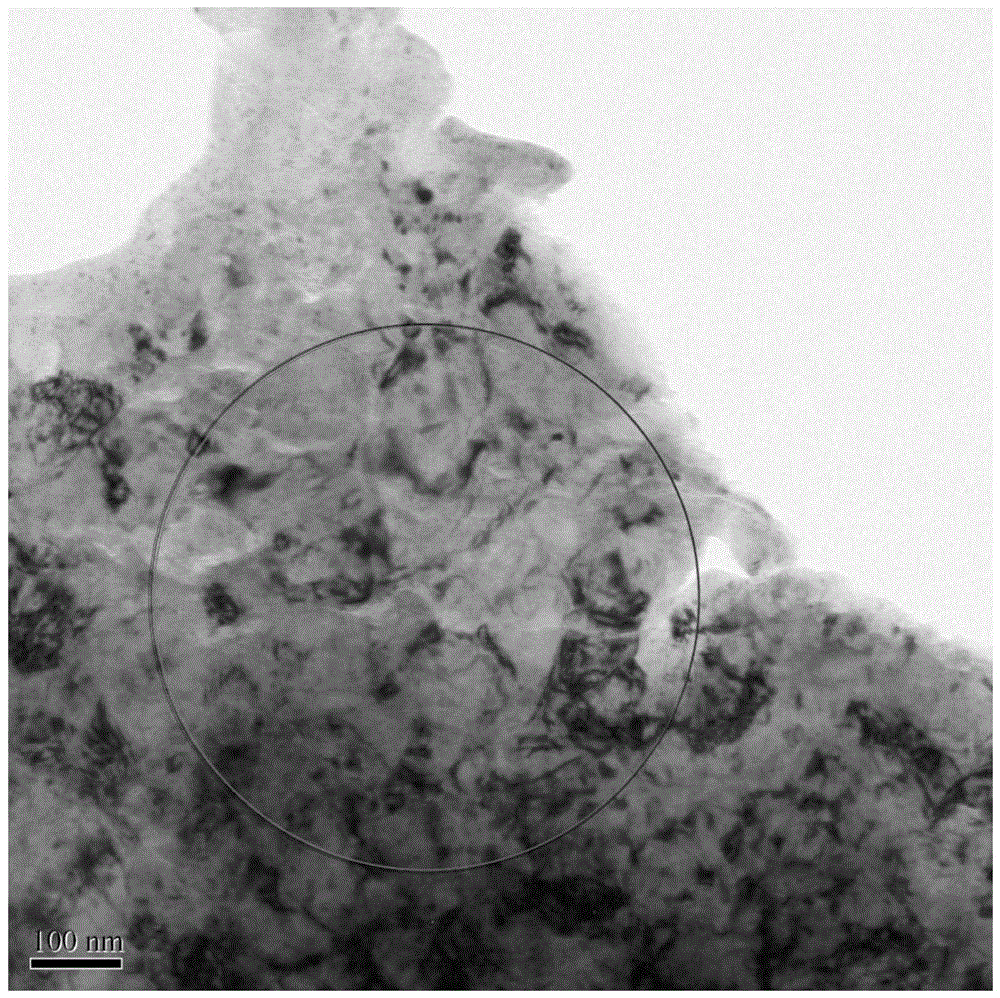

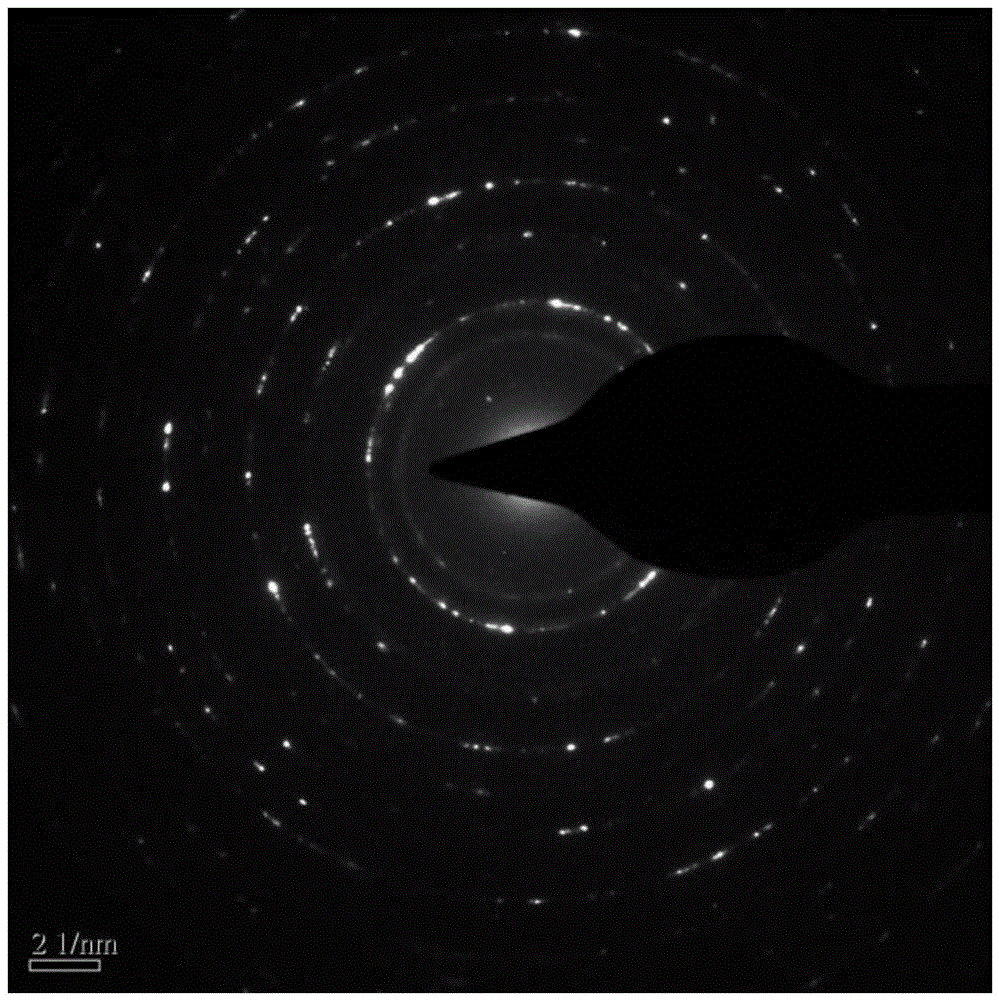

[0033] (1) Nanoization of the surface of the workpiece: After the 16Mn steel is degreased, degreased, and SiC sandpaper is gradually polished to 800 mesh, the surface of the workpiece is treated by microbead strong shot peening. The diameter of the stainless steel projectile used for microbead strong shot peening is 0.10 mm, the spraying distance is 5.5cm, the spraying pressure is 1.0MPa, and the blasting time is 6min, such as figure 1 with figure 2 It can be seen that the grain refinement effect of 16Mn steel surface microbead strong shot peening is obvious, and the average grain size after refinement is only 60nm, while figure 2 The diffraction pattern in the figure is circular, indicating that the selected area is composed of polycrystals, which further proves that the surface of the 16Mn steel has achieved nanoscale grains.

[0034] (2) Workpiece pretreatment: place the workpiece treated in step (1) in a 80°C container containing 15g / LNaOH, 10g / LNaCO 3 and 10g / LNaSiO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com