Online double phosphating method for steel wires and continuous production equipment for method

A technology for production equipment and steel wire, applied in the direction of phosphating, metal material coating technology, etc., can solve the problems of high environmental protection treatment cost, a large amount of acidic waste water and waste gas, environmental pollution, etc., to improve equipment utilization, improve multi-purpose use, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

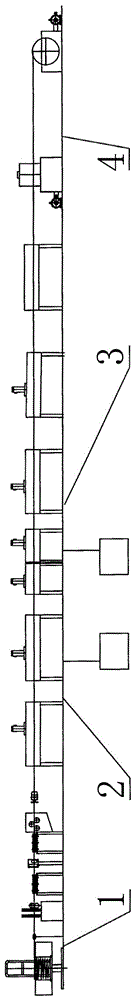

[0031] Example 1 (see figure 1 shown)

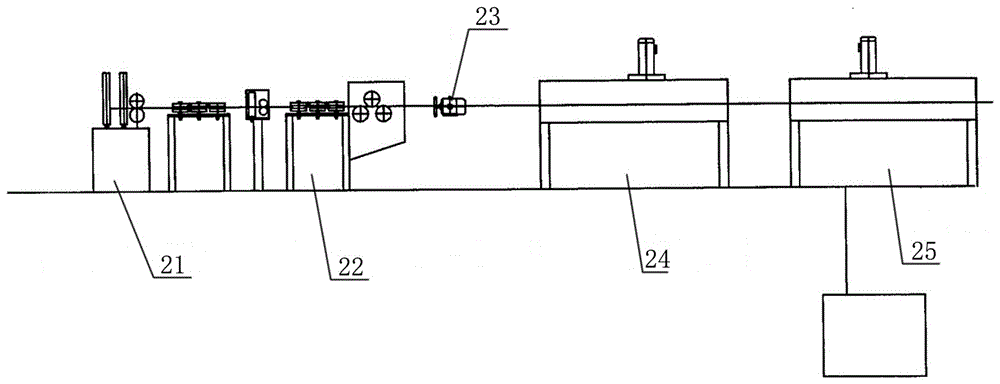

[0032] Step 1. After straightening the 10#, Φ6.5mm wire rod, pass two sets of shelling wheels 22 perpendicular to each other to realize the horizontal peeling and longitudinal peeling treatment of the oxide scale on the steel wire surface;

[0033] Step 2. After the shelled steel wire passes through the steel brush, the remaining oxide skin on the surface of the steel wire can be completely removed;

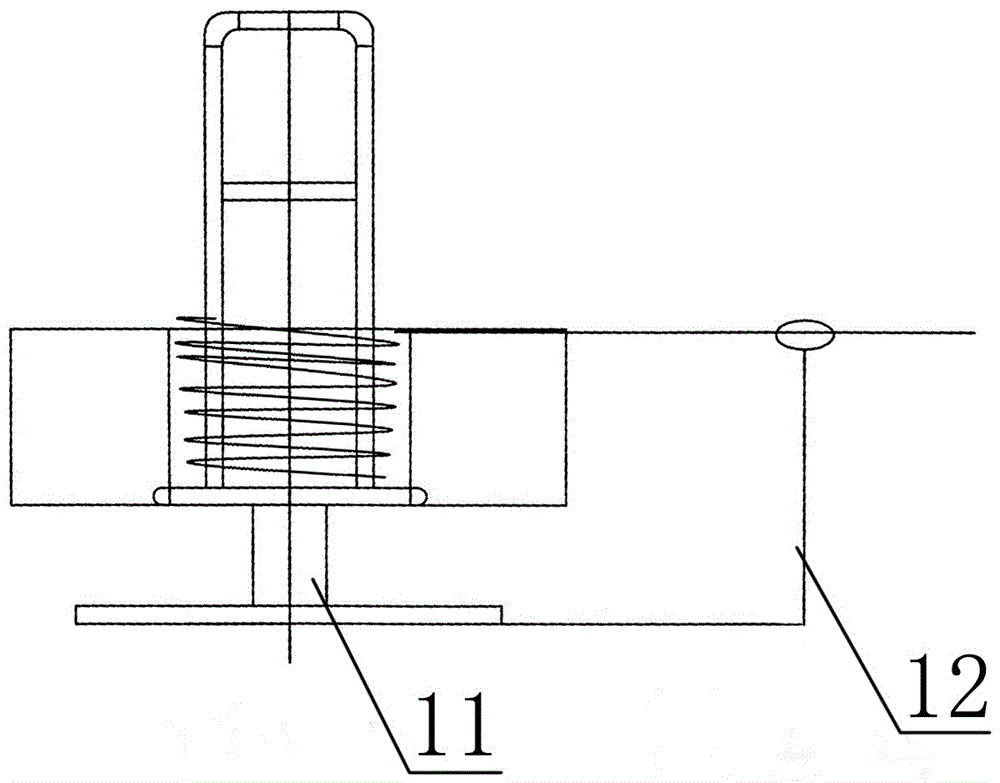

[0034] Step 3. Rinse the surface of the peeled and peeled steel wire through the washing tank I 24 equipped with steel balls and connected to high-pressure water, and then enter the low-temperature electrolytic pickling tank 25 for activation. Activation is to pass the steel wire through a phosphoric acid solution with a concentration of 15% for 5-10 seconds. Then the steel wire enters the medium-low temperature phosphating tank 31 for pre-phosphating, the phosphating temperature is 45-55° C., and the time is 10-20 seconds. The surface ...

Embodiment 2

[0038] Step 1. After straightening the 55CrSi, Φ7.3 mm peeling and normalizing wire, pass two sets of peeling wheels 22 perpendicular to each other, and select the appropriate size of the peeling wheels 22 and the wrapping angle to realize the horizontal peeling and peeling of the oxide skin on the steel wire surface. Longitudinal peeling;

[0039] Step 2. After the shelled steel wire passes through the steel brush, the remaining oxide skin on the surface of the steel wire can be completely removed;

[0040]Step 3. Rinse the surface of the peeled and peeled steel wire through the washing tank I 24 equipped with steel balls and connected to high-pressure water, and then enter the low-temperature electrolytic pickling tank 25 for activation. Activation is to pass the steel wire through a phosphoric acid solution with a concentration of 15% for 5-10 seconds. Then the steel wire enters the medium-low temperature phosphating tank 31 for pre-phosphating, the phosphating temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com