Method for preparing bioceramic membrane

A bioceramic membrane and solution technology, applied in medical science, phosphating, prosthesis, etc., can solve the problems of complicated preparation process, complicated preparation process, poor biological activity, etc., and achieve the effect of good biological activity and high bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

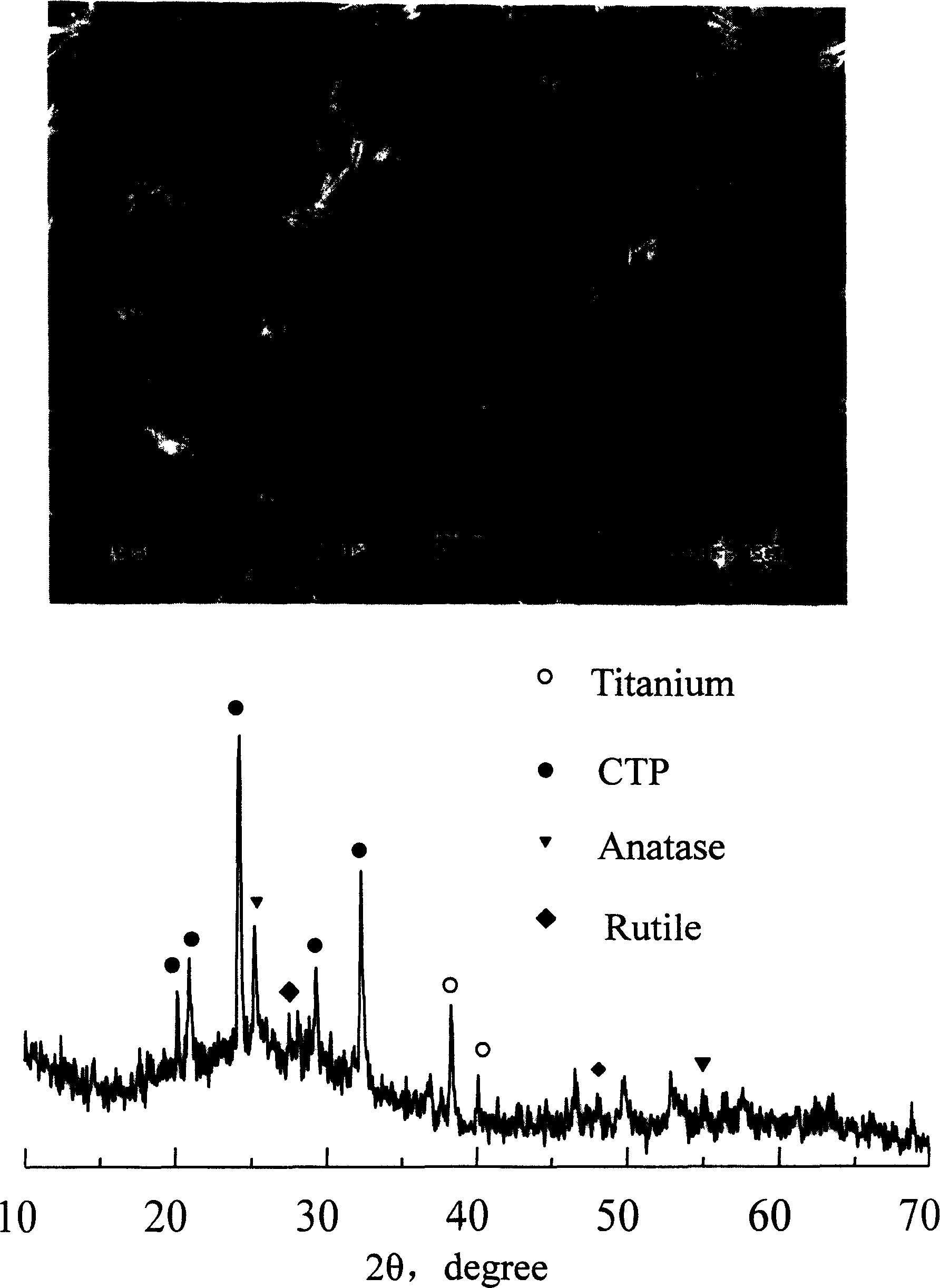

[0029] Embodiment 1. use sodium hexametaphosphate (NaPO 3 ) 6 150g / l, calcium chloride CaCl 2 2H 2 O 15g / l, pH 9 solution, titanium as anode, stainless steel as cathode, DC power supply 150V, current density 50mA / cm 2, micro-arc oxidation for 30 minutes under the condition of pole distance of 10 cm, a porous layer with a thickness of about 50 μm is formed on the titanium surface, and the scanning electron microscope photo is as attached figure 1 ; X-ray diffraction analysis shows that the coating is composed of titanium dioxide and CTP, with a bonding strength of 44.7MPa. It is soaked in artificial body fluid for 11 days to induce the deposition of hydroxyapatite, which has good biological activity.

Embodiment 2

[0030] Embodiment 2. use sodium hexametaphosphate (NaPO 3 ) 6 90g / l, calcium chloride CaCl 2 2H 2 O 10g / l, pH 10 solution, titanium as anode, stainless steel as cathode, DC power supply 140V, current density about 45mA / cm 2 , micro-arc oxidation for 40min under the condition of pole distance of 10cm forms a porous layer with a thickness of about 45μm on the titanium surface. X-ray diffraction analysis shows that the coating is composed of titanium dioxide and CTP, and hydroxyapatite is induced to deposit after soaking in artificial body fluid for 13 days, which has good biological activity.

Embodiment 3

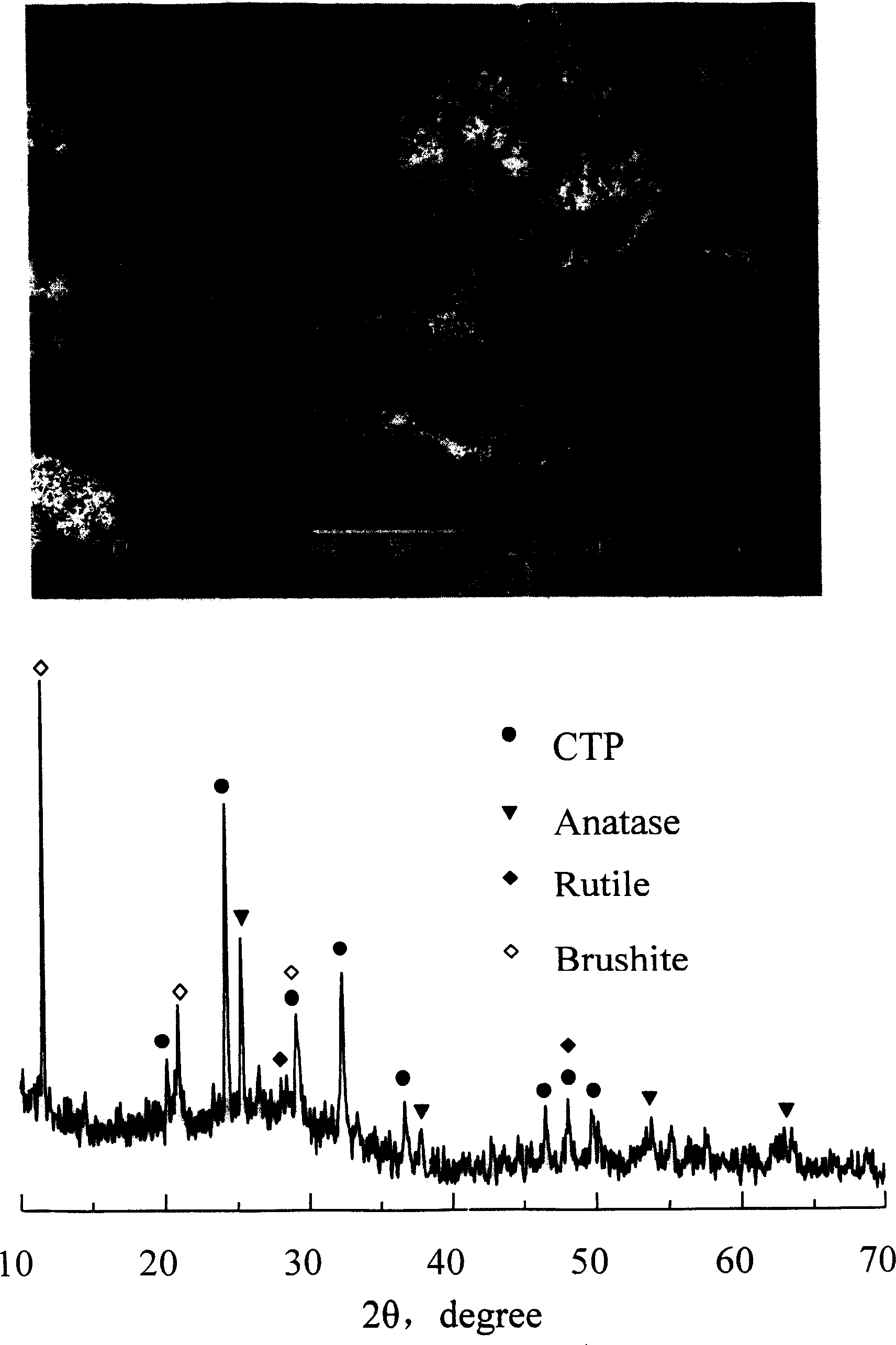

[0031] Embodiment 3. use sodium hexametaphosphate (NaPO 3 ) 6 10g / l, calcium chloride CaCl 2 2H 2 O 1.5g / l, pH 10 solution, titanium as anode, stainless steel as cathode, DC power supply 250V, current density 100mA / cm 2 , micro-arc oxidation for 30 minutes under the condition of pole distance of 10 cm, a porous layer with a thickness of about 50 μm is formed on the titanium surface, and the scanning electron microscope photo is as attached figure 2 ; X-ray diffraction analysis shows that the coating is composed of titanium dioxide, CTP, CaHPO 4 2H 2 Composed of O, with a binding strength of 37.3MPa, hydroxyapatite is induced to be deposited by immersion in artificial body fluid for 5 days, and has good biological activity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com