Method for manufacturing anodic foil of aluminum electrolytic capacitor

A technology for aluminum electrolytic capacitors and manufacturing methods, which is applied in the direction of electrolytic capacitors, capacitors, circuits, etc., can solve problems such as long hydration-resistant boosting time, decreased oxide film withstand voltage value, and fast boosting time recovery, etc., to improve product quality , the bending strength is improved, and the production process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

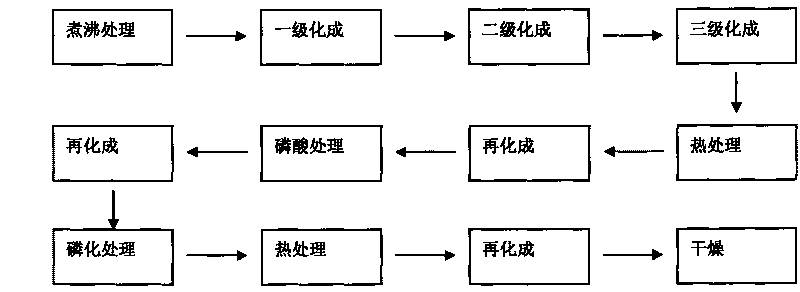

Image

Examples

Embodiment 1

[0013] Use a medium-pressure corroded foil with a purity of more than 99.99% to boil in pure water at 96°C for 5 minutes, then conduct a primary constant pressure 130V formation for 10 minutes in the formation solution of citric acid and its salts; Secondary constant voltage 280V formation for 10min in the formation solution of salts; followed by a third level constant pressure 315V formation for 20min in the formation solution of azelaic acid and its salts; heat treatment at 400°C for 1min; Press 315V for 10 minutes; perform phosphoric acid treatment in 1v / v% phosphoric acid solution at 80°C for 5 minutes; phosphating treatment is immersion treatment at 5v / v% concentration of phosphoric acid-based treatment agent at 80°C for 1min , the phosphoric acid-based treatment agent is phosphoric acid. The temperature of the second heat treatment is 400° C. for 1 min.

[0014] After testing for 3 months of storage, the variation of the voltage rise time of the oxide film of the anode ...

Embodiment 2

[0019] Use a high-pressure corroded foil with a purity of more than 99.99% to boil in pure water at 96°C for 10 minutes, then conduct a primary constant pressure 200V formation for 15 minutes in the formation solution of citric acid and its salts; Carry out secondary constant pressure 400V for 15min in a similar chemical forming solution; followed by a third level of constant pressure 530V for 30min in a chemical forming solution containing azelaic acid and its salts; heat treatment at 500°C for 3min; Press 530V for 15 minutes; carry out phosphoric acid treatment in 6v / v% phosphoric acid solution at 70°C for 10 minutes; phosphating treatment is immersion treatment at 60°C for 5 minutes at a concentration of phosphoric acid-based treatment agent of 2v / v% , the phosphoric acid-based treatment agent is phosphorous acid. Ammonium dihydrogen solution and 85% phosphorous acid. The temperature of the second heat treatment is 300° C. for 3 minutes.

[0020] After testing for 3 month...

Embodiment 3

[0025] Use a high-pressure corroded foil with a purity of more than 99.99% to boil in pure water at 96°C for 15 minutes, and then conduct a primary constant pressure 250V formation for 20 minutes in the formation solution of citric acid and its salts; Carry out secondary constant pressure 480V for 20min in the chemical forming liquid of azelaic acid and its salts; then carry out three-stage constant pressure 590V for 40min in the chemical forming liquid of azelaic acid and its salts; conduct heat treatment at 550°C for 5min; 590V for 20 minutes; phosphoric acid treatment in 10v / v% phosphoric acid solution at 60°C for 15 minutes; phosphating treatment is 10 minutes of immersion treatment at a concentration of phosphoric acid-based treatment agent at 1v / v% and a temperature of 20°C. The phosphoric acid-based treatment agent is 50 wt% ammonium dihydrogen phosphate solution and 50 wt% ammonium hypophosphite solution. The temperature of the second heat treatment is 80° C. for 5 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com