Inner cylinder rotating type biomass particle burner

A biomass particle, rotary technology, applied in the combustion method, combustion equipment, combustion of solid fuel and other directions, can solve the problems of easy slagging and insufficient combustion of biomass particles, and achieves the goal of not easy slagging, compact structure, full burn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

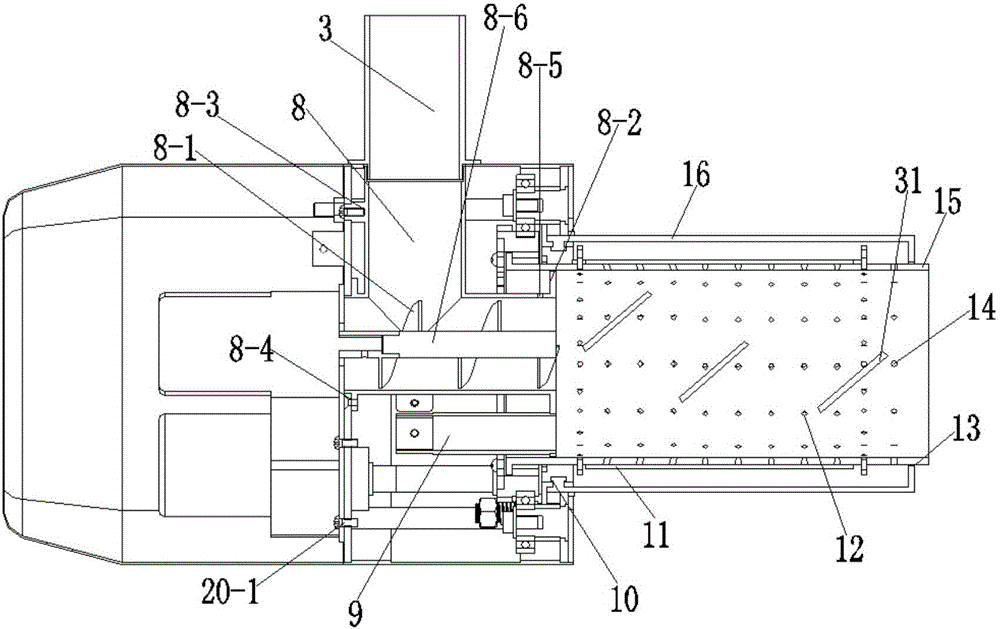

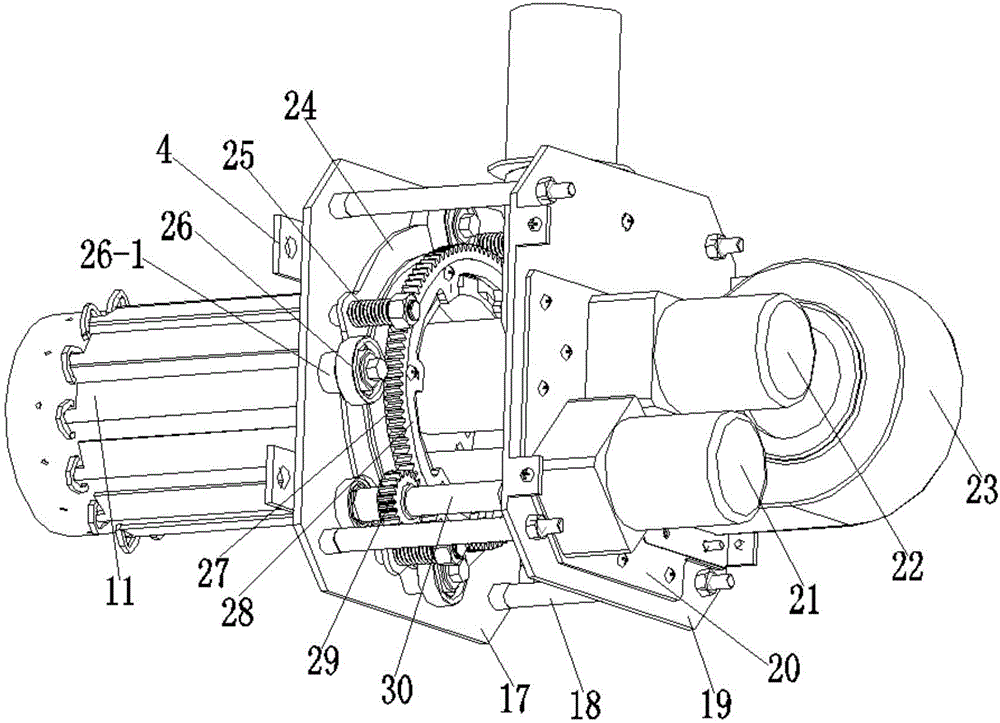

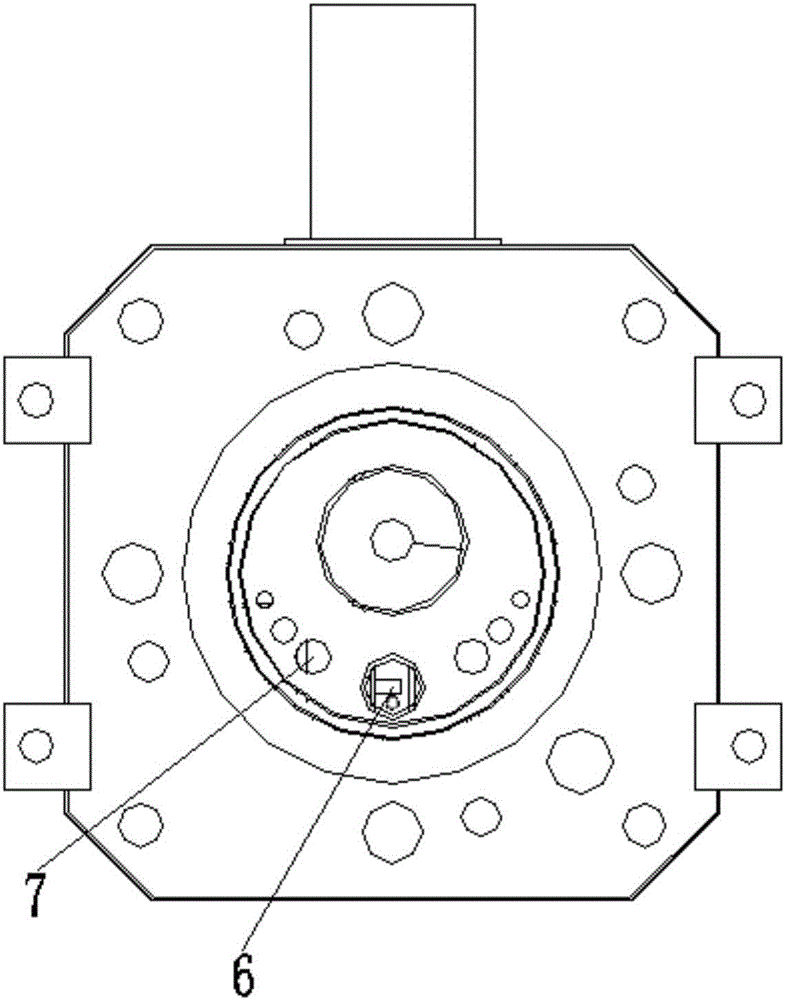

[0021] Inner barrel rotary biomass particle burner of the present invention, such as figure 1 , figure 2 As shown, it includes a front mounting plate 17 and a rear mounting plate 19 which are oppositely arranged and connected, and a combustion tube is installed on the side of the front mounting plate 17 away from the rear mounting plate 19. The combustion tube is composed of a combustion inner cylinder 15 and a combustion outer cylinder 16. Combustion The outer cylinder 16 is coaxially socketed on the outside of the combustion inner cylinder 15, leaving a gap between the combustion inner cylinder 15 and the combustion outer cylinder 16; the outer wall of the combustion inner cylinder 15 is provided with multiple rows of secondary air tangential air holes 12 along the axial direction, each The row of secondary air tangential air holes 12 are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com