Large dynamic gasification combustion biomass burning machine

A biomass and burner technology, applied in the direction of combustion methods, combustion equipment, solid fuel combustion, etc., can solve problems such as burner instability, environmental pollution, combustion backfire, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

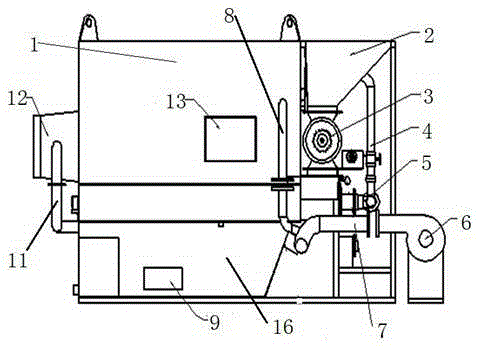

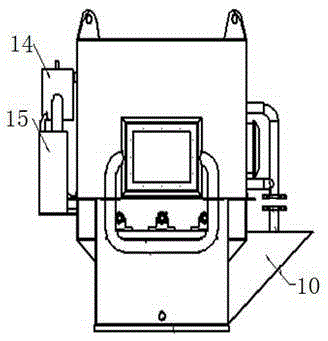

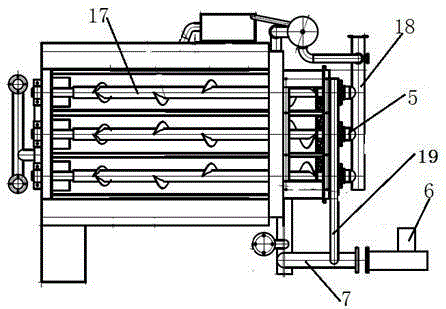

[0028] Embodiment one of the large-scale dynamic gasification combustion biomass burner of the present invention, such as Figure 1~11 As shown, it includes a combustion chamber 1 arranged horizontally, a feeding system and an air duct system, the feeding system includes a material box 2 and three feeding augers 5, the lower outlet of the material box 2 is connected with an airtight device 3, The airtight device 3 is used to prevent smoke from entering the hopper, the bottom of the airtight device 3 is connected to the input end of the feed auger 5, the output end of the feed auger 5 is connected to the combustion chamber 1, and the output end of the feed auger 5 The rotating shaft 17 at the end extends through the combustion chamber and is fixed on the casing of the combustion chamber through a bearing seat. The lower part of the rotating shaft 17 is a large air chamber. It communicates with the large air chamber, and a fire outlet 12 is provided on the left side of the combu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com