A kind of miniature non-premixed burner with corrugated plate

A corrugated plate and burner technology, applied in the field of micro-miniature non-premixed burners, can solve the problems of complicated internal structure and processing technology of the burner, limited flame stability of the micro-burner, uneven thermal stress, etc. Fire risk, enhanced flame stability, enhanced mixing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

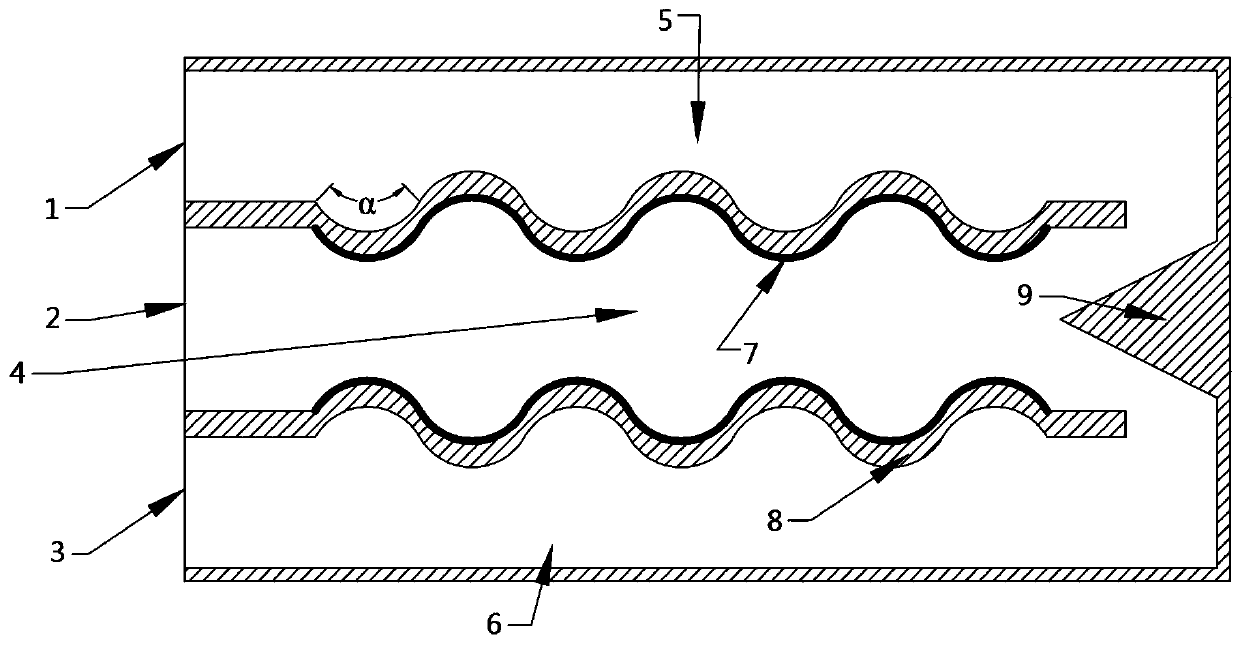

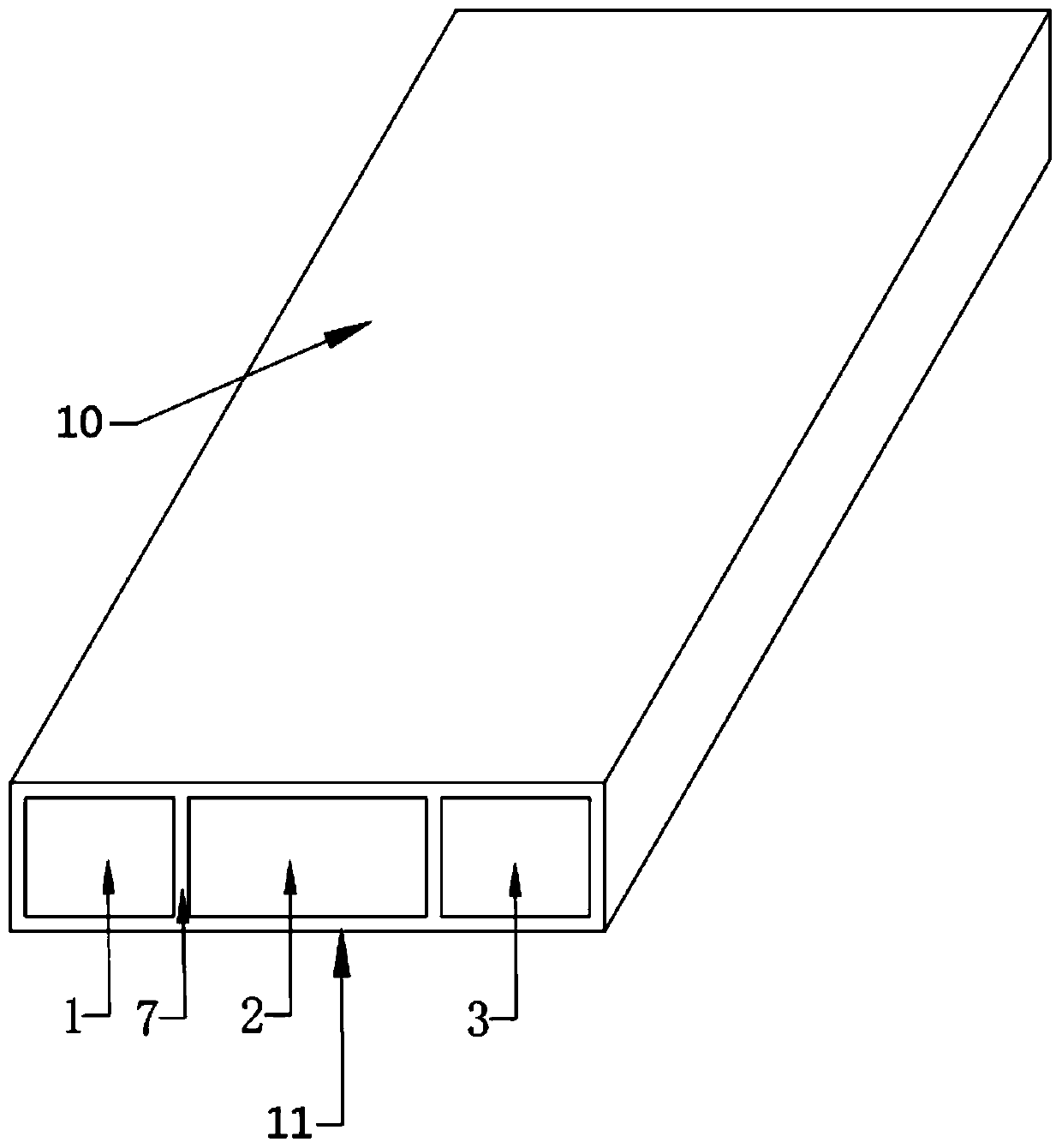

[0043] The specific parameters of the embodiment are as follows: the fuel is hydrogen, and the oxidant is air. The length, width and height of the burner are 40mm, 20mm and 5mm respectively. The number of corrugations is 4, the corrugation radian α is 60°, and the surface of the corrugated plate facing the combustion chamber is coated with catalyst. The cross-section of the turbulent body is an equilateral triangle with a side length of 6mm.

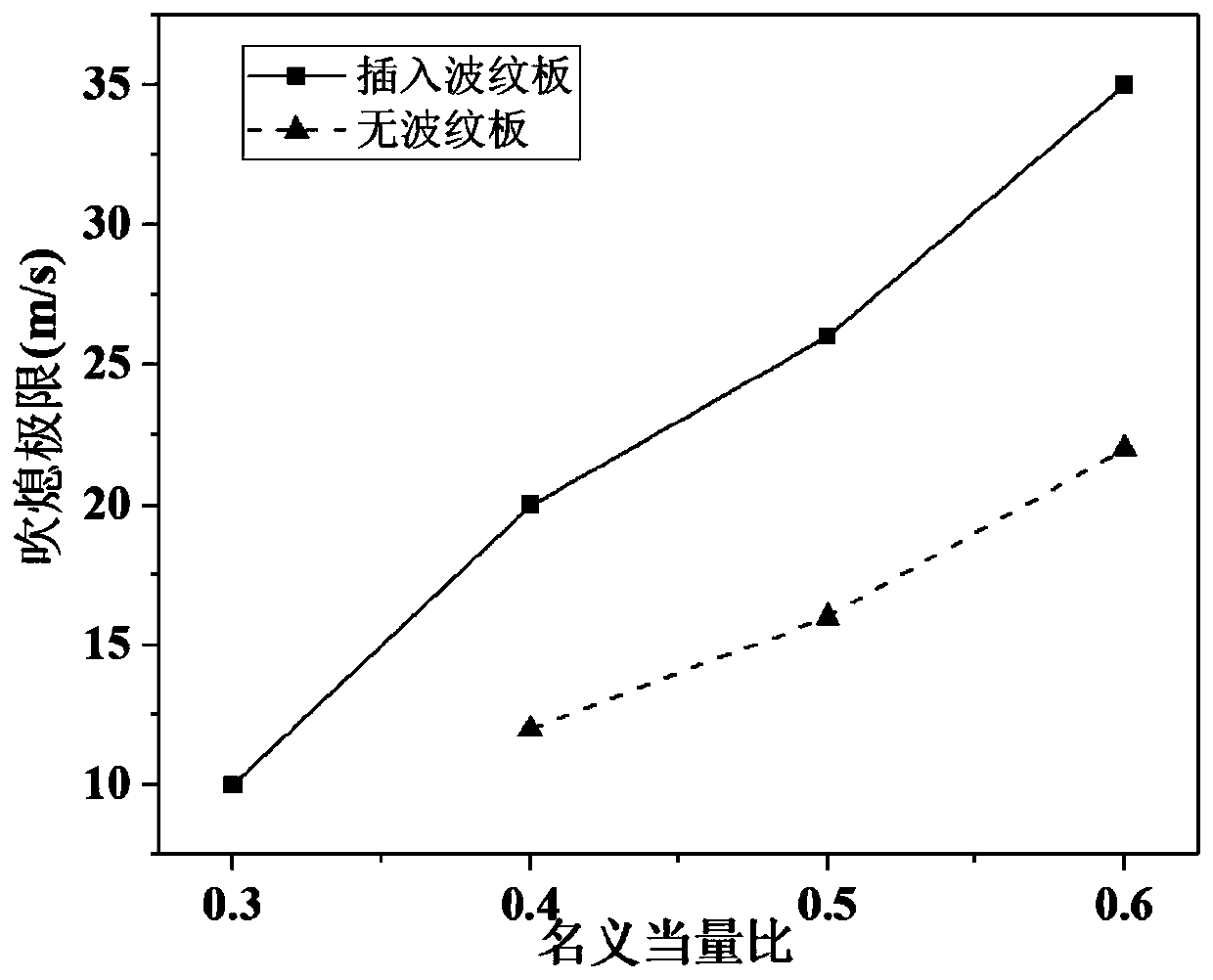

[0044] image 3 It is a comparison of the blow-out limit of the miniature non-premixed burner with corrugated plate and the miniature non-premixed burner with straight channel constructed according to the preferred embodiment of the present invention. From image 3 It can be seen that, when the nominal equivalence ratio is 0.4, 0.5, 0.6, adding the corrugated plate increases the blow-out limit of the burner, especially when the nominal equivalence ratio is 0.3, the straight channel burner without the corrugated plate is at all speeds ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com