Multifunctional spiral plate dephlegmator and working method thereof

A shrinker and spiral plate technology, which is applied in the field of multifunctional spiral plate shrinkers, can solve the problems of low heat transfer efficiency, liquid flooding, and fast flow of mixed steam, so as to improve heat transfer efficiency and reduce entrainment , Improve the effect of water side heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

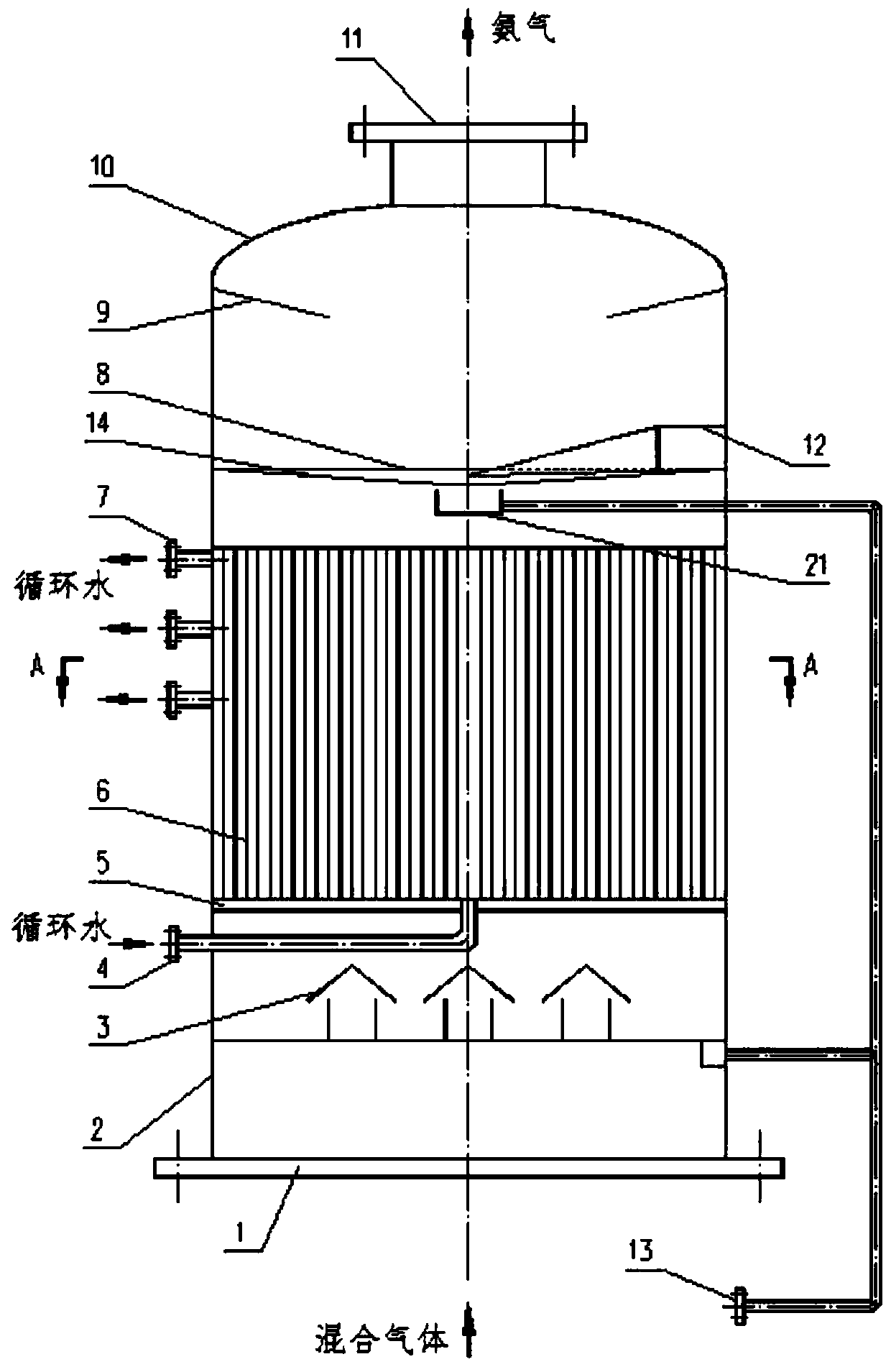

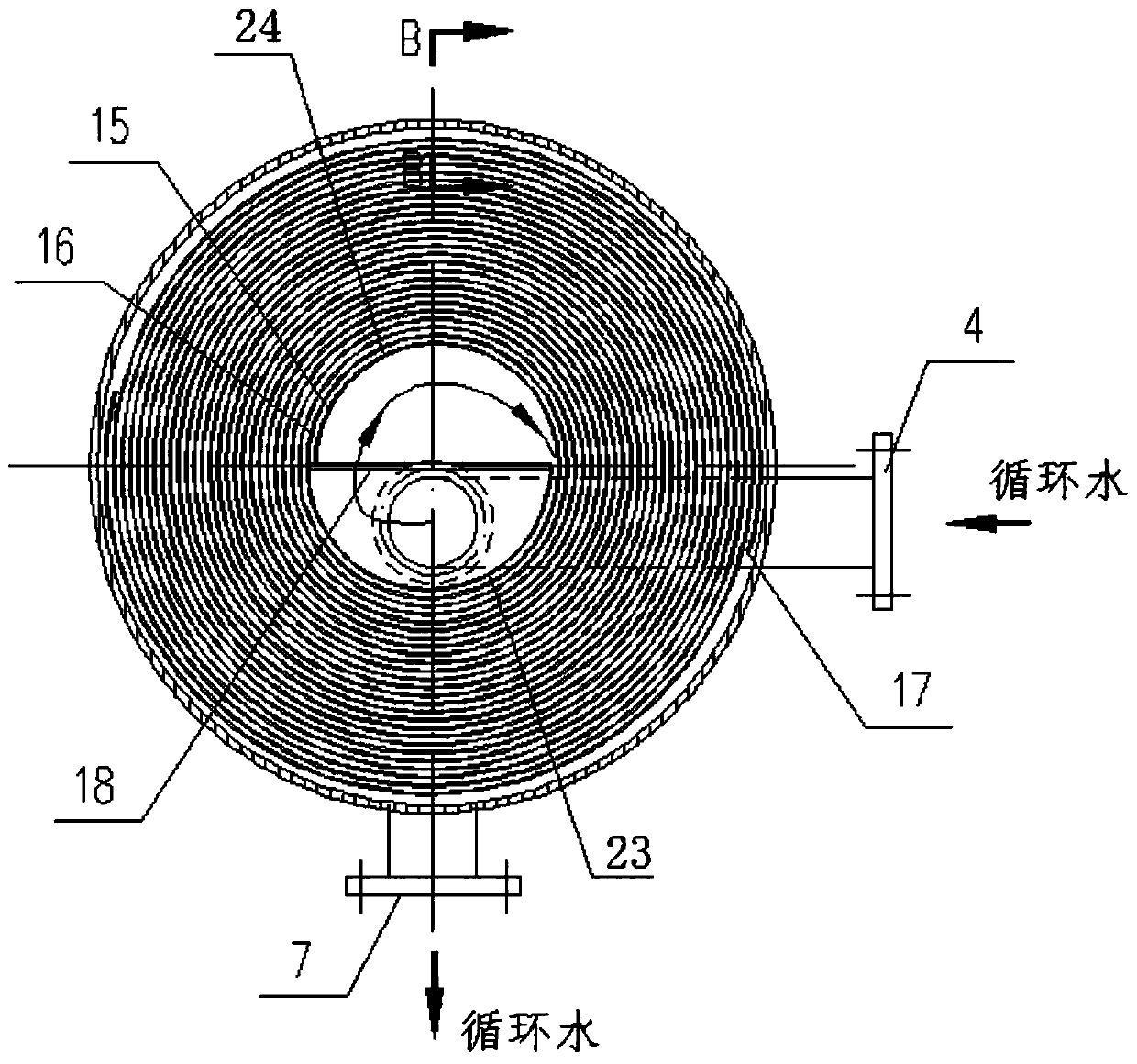

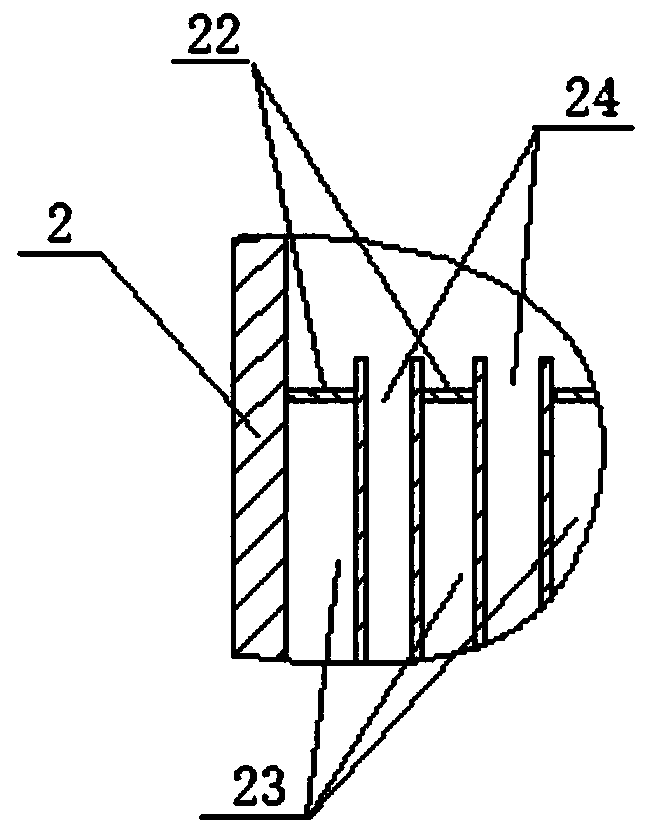

[0036] like figure 1 As shown, a multifunctional spiral plate shrinker according to the present invention includes a shrinker cylinder 2 and a liquid baffle 9 sequentially arranged in the shrinker cylinder 2 from top to bottom, and a conical spiral separation device 8. The spiral plate heat exchange device 6 and the liquid collecting device 3; the top of the shrinker cylinder 2 is provided with an ammonia gas outlet 11, and the flange 1 at the bottom is used to connect with the mixed steam outlet at the top of the ammonia distillation tower; figure 2 As shown, the spiral plate heat exchange device 6 is composed of coil one 15, coil two 16, connecting reinforcement plate 18, edge blocking plate 22, end blocking plate 17, circulating water outlet 4, circulating water outlet 7 The first coil 15 and the second coil 16 are evenly wound in the splitte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com