Integrated structure of drive controller and direct current converter

A DC converter and drive controller technology, which is applied in the direction of output power conversion devices, electrical components, cooling/ventilation/heating transformation, etc., can solve the problems of large vehicle space, space occupation, and high material cost, and reduce layout Complexity, space saving, effect of improving cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

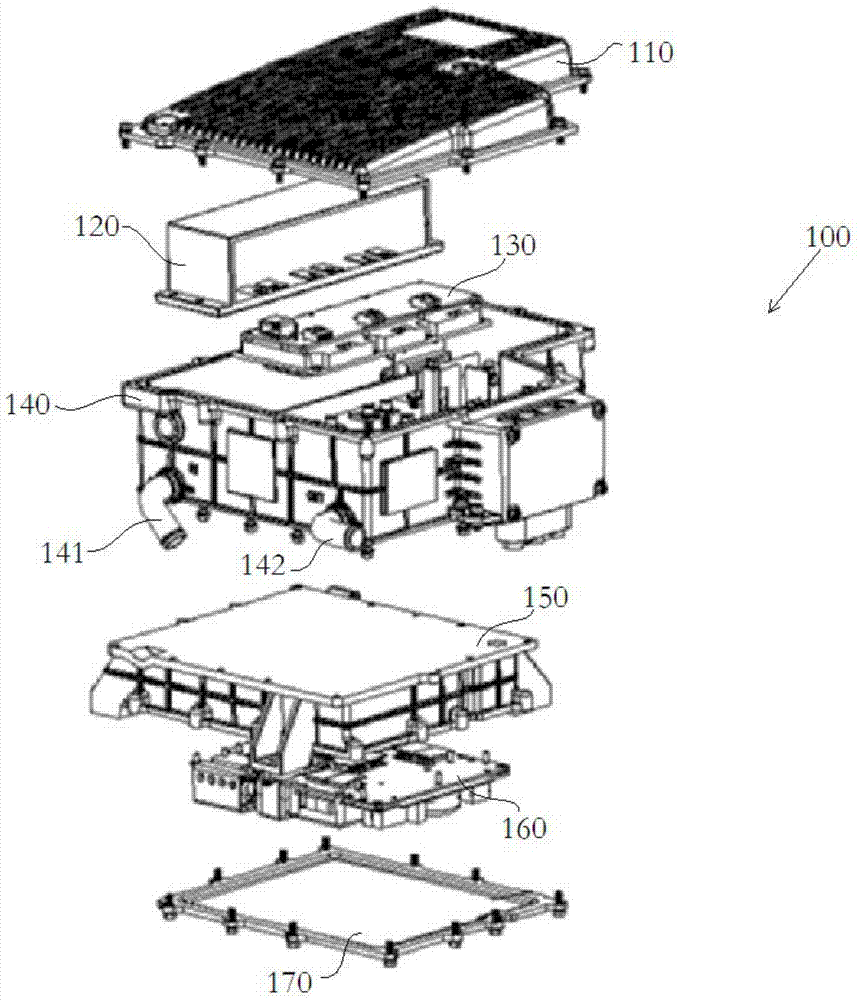

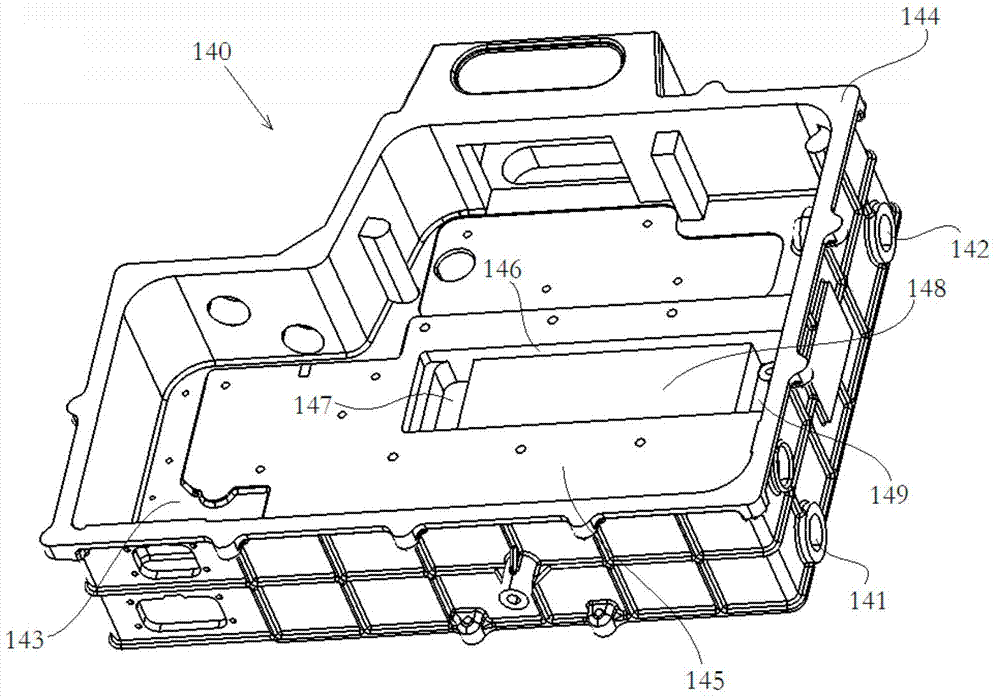

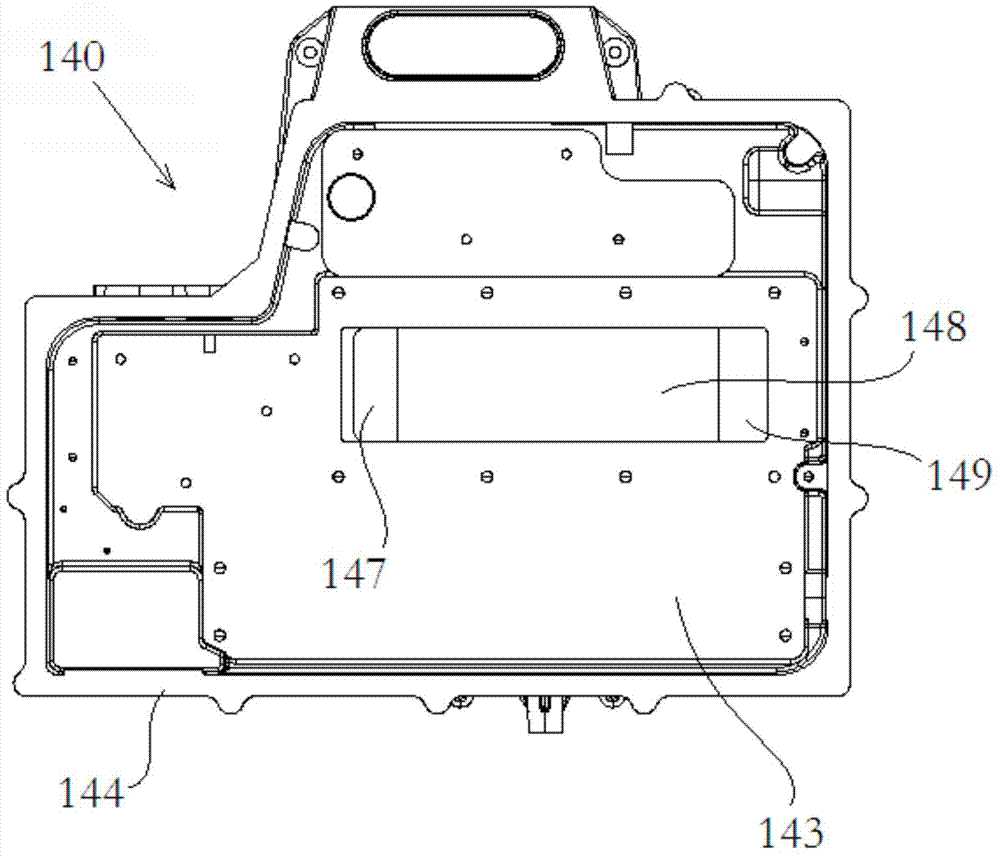

[0027] refer to figure 1 , the shell of the integrated structure 100 of the drive controller and the DC converter mainly includes an upper cover 110, a drive controller housing 140, a DC converter housing 150 and a lower cover 170, and the internal components mainly include a film capacitor 120, IGBT (Insulated Gate Bipolar Transistor, insulated gate bipolar transistor) module 130 and DC conversion module 160 . Drive control modules including film capacitors 120 , IGBT modules 130 , drive boards and control boards not shown are installed in the drive controller housing 140 , and are closed with the upper cover 110 . A DC converter module 160 is installed in the DC converter housing 150 and is closed by a lower cover plate 170 . Among them, the IGBT module 130 belongs to the heating module in the drive controller, and the DC conversion module 160 will also generate relatively high heat during operation. They all need to be cooled, or there are other components that need to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com